21

PROBLEM CAUSE SOLUTION

Excessive vibration/

knocking

Loose/worn connecting rod Repair connecting rod

Carbon in combustion

chamber

Clean carbon from chamber

Bentcrankshaft Disassemblecrankcaseand

repair

Engine mount damaged Checkenginemountingbolts

or replace rubber isolator

Timing out Checkflywheelkey

SPEED/GOVERNOR ADJUSTMENT

If speeds are out of adjustment use this procedure to reset to factory settings.

1.Back off both idle adjustment screws far enough so they are out of the way.

NOTE: Thisistheblackplasticscrew(L3,Q2)atcarburetorandthescrewwiththe

blackspringundertheheadonthesolenoidL-shapedlinkage(ifequipped).

C5

E5, Q5

F2

L3, Q2

N5, Z4

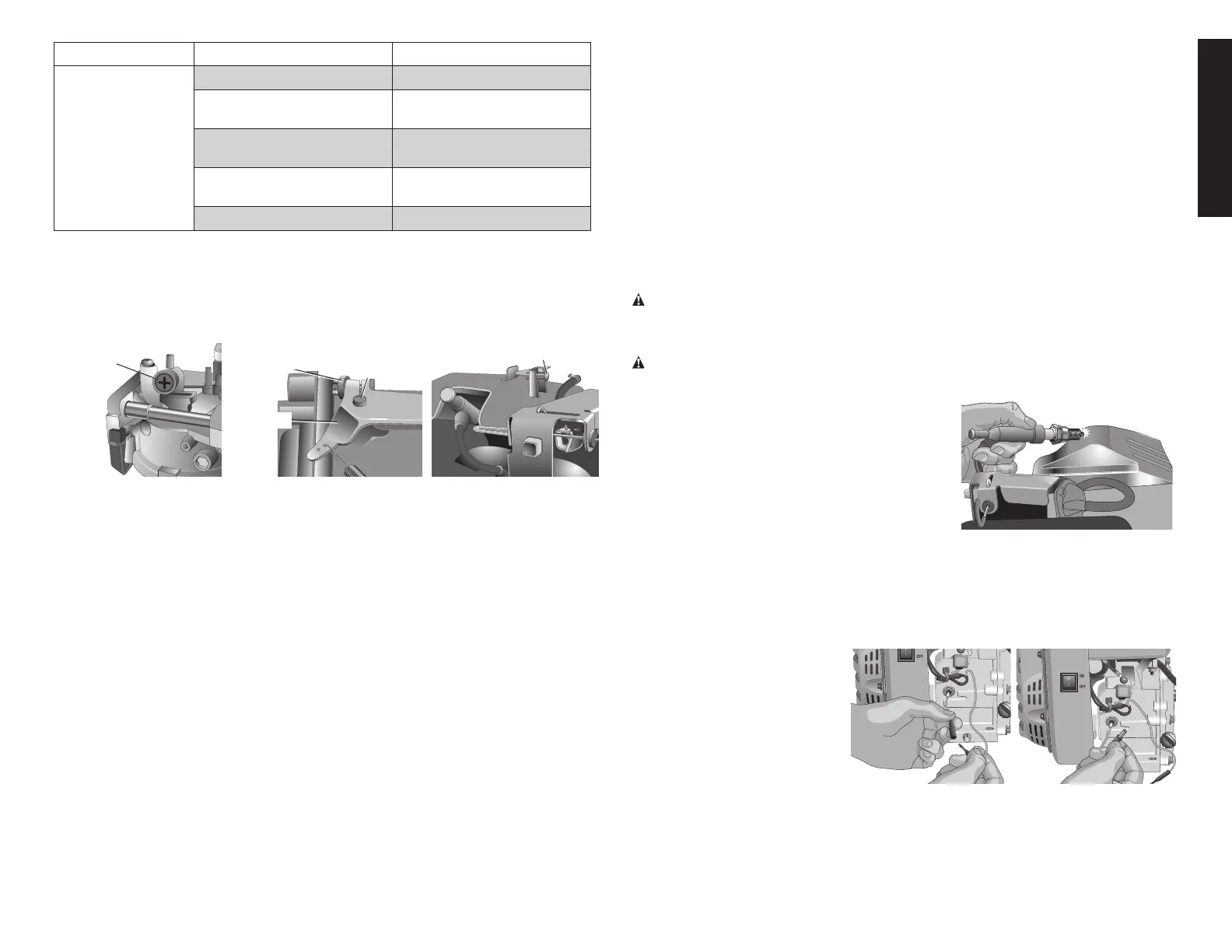

2.Loosenthegovernorarm(E5,Q5)fromtheshaft(F2)comingoutofthetopofengine.

On 9 and 13 HP engines:

Rotate the shaft counterclockwise with the governor arm held to the right at WOT

(wideopenthrottle).Makesuregovernor armremainsstraightanddoesnotpivotat

thejointin the middle(ifequipped). Retighten governorarmto shaft inthisextreme

position.

On 6.5 HP engines:

Rotate the shaft clockwise with the governor arm held to the right at WOT (wide open

throttle).Retightengovernorarmtoshaftinthisextremeposition.

3.Governorspring(largesilver)shouldbeintheholeonthegovernorarmclosesttothe

shaft.

4.Backouthighspeedadjustmentscrew(N5,Z4)ontopoftheengineatthesmallsilver

lever. A few complete turns will do.

5.Starttheengine.Ifithunts(speedvariesupanddown.),movethegovernorspringto

theouterhole,ifpoweristoolowmoveitbackintowardtheshaft.NOTE: Hunting is

unpredictable and sometimes the opposite movement of the spring helps.

6. Engine will probably be running slow. Adjust high speed to 3600 rpm by turning high

speedscrew(N5,Z4)ontop,intoincreasespeedandouttoslowdown.Ifenginestill

runs to fast, governor arm may still be out of adjustment on shaft or it has moved since

tightening.Ortherecouldbeaninternalgovernorissue(thisisrare).

NOTE: If governor arm was over tightened to shaft and has no gap at the end of the

arm next to the shaft, over tightening of the governor arm will not result in sufficient

holding force to shaft. The governor arm must be replaced.

7.Withengineoff,ensureidlelinkagesonsolenoidarenotbindingandarefreetomove

thefulltravel.Alsomakesurethrottlelinkagefromcarburetortogovernorarmmoves

backandforthfreely.

8.Ensuretheidlescrew(withblackspringundertheheadontheL-shapedleveronthe

solenoid) isbacked outfarenoughtojustclear touchingthegovernorarmwithidle

control turned off.

9. Start the engine. Turn idle control on after engine has warmed up some. Solenoid

shouldpushgovernorarmandthrottletothelefttowardcarburetorandtheblackplastic

throttleshouldstopupagainstblackplasticscrew(L3,Q2).Adjusttheidlespeedto

2700–2800RPMbyadjustingthisscrewintoincreaseidlespeed,backitouttoreduce.

Ifsolenoiddoesnotpushleveroverfarenoughtotouchblackplasticscrew(thescrew

withthe blackspring onthe L-shaped solenoid lever) canbe turned into makethis

happen. Both of these screws can be adjusted in our out so one is not at the extreme

of it's adjustment length.

10.Cycleidlecontrolswitchonandoffafewtimesandcheckbothhighspeedandidle

speed to ensure they are still correct.

IGNITION TEST

CHECK FOR SPARK

WARNING: Risk of explosion.

Spilled gas o line and it’s vapors can be come ignited from

sparks from smoking products, electrical arcing, exhaust, flame, gas es and hot engine com-

ponents such as the muffler.

Make sure there are no sources of ignition, such as smoking

products near servicing location. Wipe any fuel spillage from engine.

WARNING:

• Neverholdthesparkplugwirewithwethandswhileperformingtest.

• Wipeanyfuelspillagefromengine.

• Makesurethesparkplugisnotwetwithfuel.

• Donotallowsparksneartheplughole.

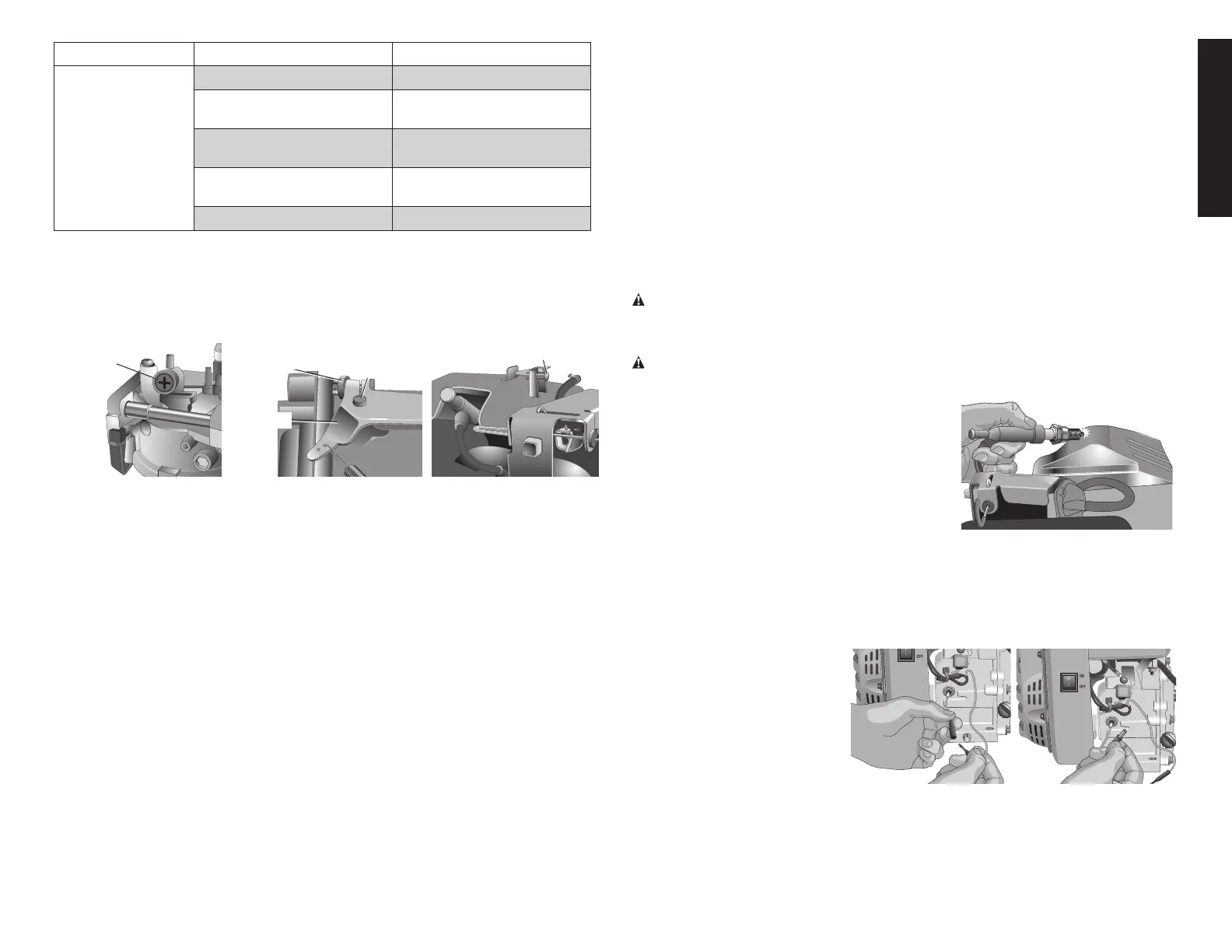

1.Removethesparkplugfromthecylinderhead.

2.Groundsparkplugagainstairshroudasshown.

3. Place the on/off switch in the “ON” position and

cranktheengine.

4.Check to see if the spark bridges the electrode

gap.Ifyoucanseethespark(thismaybedifficult

inbrightdaylight)theproblemismostlikelynottheignitionsystem.Ifsparkplugfails

tospark,seeFlywheel Ignition Inspection.

OIL ALERT TEST

Perform this check if the engine will not start and other troubleshooting attempts

have failed. Ensure oil is a proper level, see Oil under Maintenance.

Engine will not start:

Disconnect the lead from the oil alert

sensor and directly connect the

leads from the ignition switch and

the ignition bypassing the low oil

sensor. If the engine starts replace

the sensor.

Engine will not stop:

With the engine running disconnect

the oil alert sensor lead and ground

it against the engine. If the engine does not stop replace the sensor.

Loading...

Loading...