50

InspeCtIon

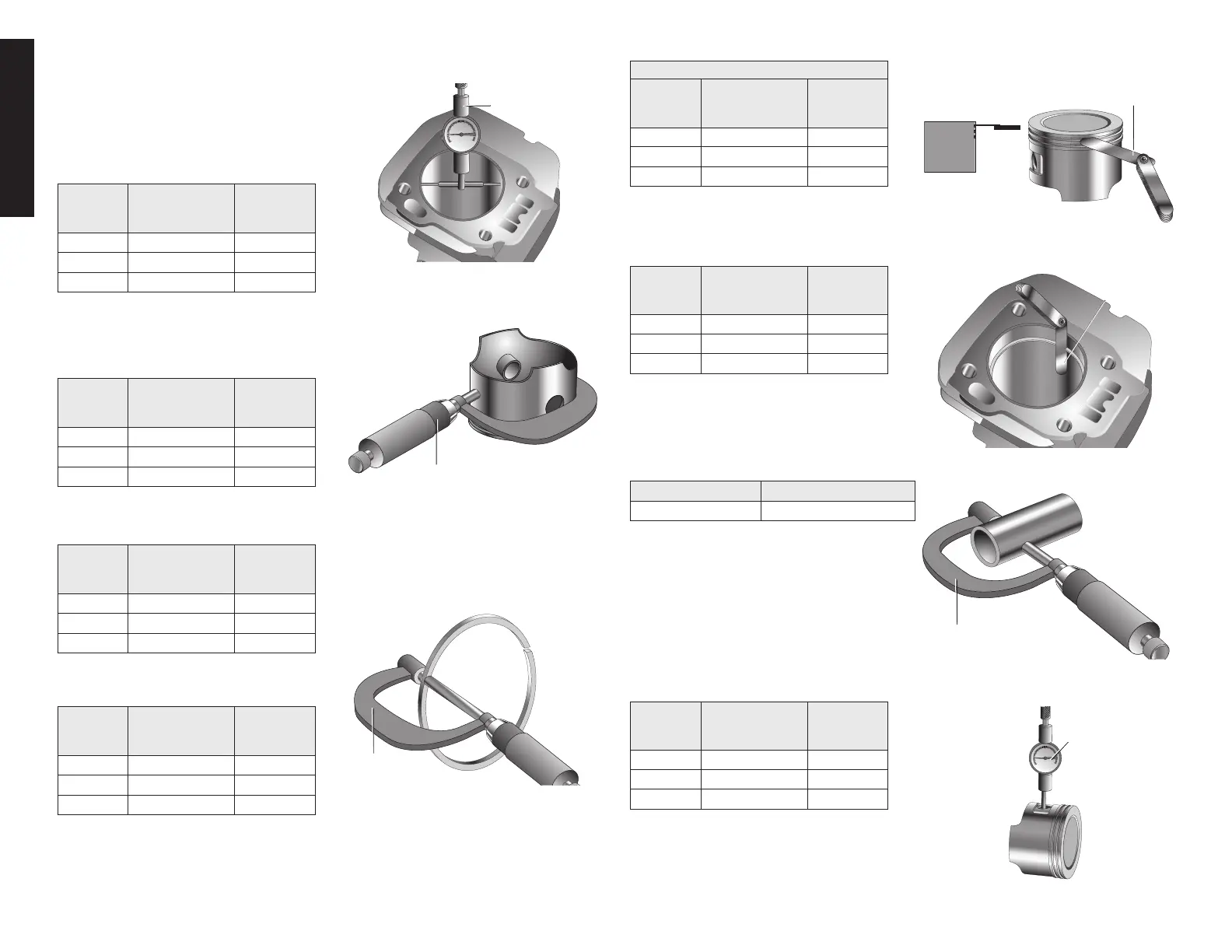

CYLINDER I.D.

Measure and record the cylinder I. D. at three

levels in both the "X" axis (perpendicular to

thecrankshaft)andthe"Y"axis(parallelto

crankshaft).

Take the maximum reading to determine

cylinder wear and taper.

modeL

Standard

(mm)

Service

Limit

(mm)

dW168

68.015~68.025 68.156

dW177

77.02~77.03 77.179

dW188

88.015~88.025 88.195

PISTON SKIRT O.D.

Measure and record the piston O. D. at a point

of10mm(0.4")fromthebottomoftheskirt

and 90° to the piston pin bore.

modeL

Standard

(mm)

Service

Limit

(mm)

dW168

67.975~67.985 67.850

dW177

76.970~76.980 76.850

dW188

87.970~87.980 87.850

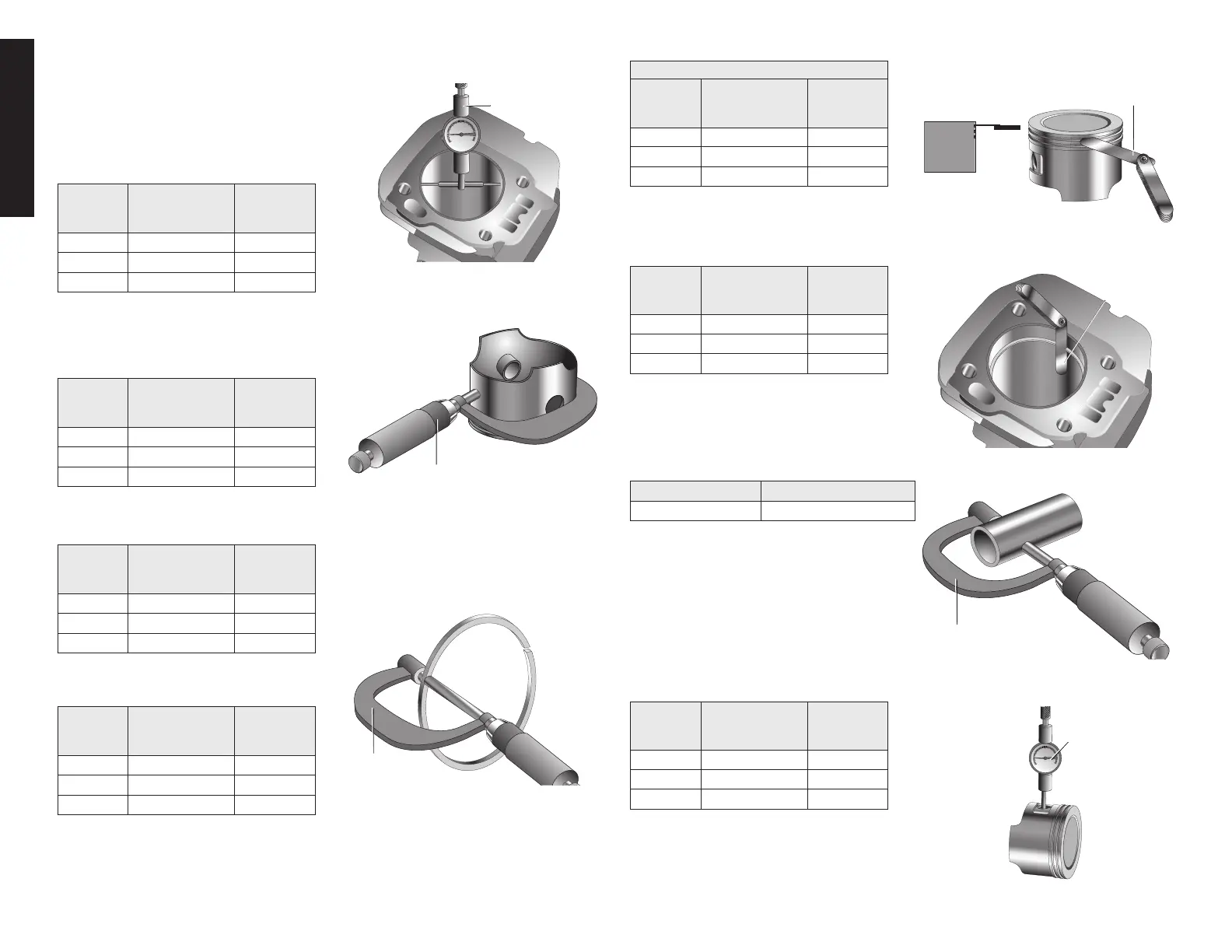

PISTON TO CYLINDER CLEARANCE

modeL

Standard

(mm)

Service

Limit

(mm)

dW168

0.030~0.050 0.120

dW177

0.040~0.060 0.100

dW188

0.045~0.065 0.100

PISTON RING WIDTH

modeL

Standard

(mm)

Service

Limit

(mm)

dW168

1.450 1.200

dW177

2.000 1.750

dW188

2.000 1.250

PISTON RING SIDE CLEARANCE

RING, TOP

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

0.08~0.12 0.10

dW177

0.02~0.06 0.15

dW188

0.02~0.06 0.15

PISTON RING END GAP

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

0.15~0.35 1.00

dW177

0.20~0.35 1.00

dW188

0.20~0.40 1.00

NOTE: Use the top of the piston to position the

ring horizontally in the cylinder.

PISTON PIN O. D.

STANDARD (MM) SERVICE LIMIT (MM)

17.992~17.998 17.940

PISTON PIN BORE I. D.

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

18.002~18.008 18.042

dW177

18.002~18.008 18.042

dW188

20.002~20.008 20.042

MICROMETER

FEELER

GUAGE

FEELER

GUAGE

MICROMETER

MICROMETER

DIAL INDICATOR

BORE GAUGE

DIAL INDICATOR

BORE GAUGE

Loading...

Loading...