51

PISTON PIN TO PISTON PIN BORE CLEARANCE

STANDARD (MM) SERVICE LIMIT (MM)

0.004~0.016 0.08

CONNECTING ROD SMALL END I. D.

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

18.011~18.022 18.06

dW177

18.011~18.022 18.06

dW188

20.011~20.022 20.06

CONNECTING ROD BIG END I. D.

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

30.02~30.03 30.06

dW177

33.02~33.03 33.06

dW188

36.02~36.03 36.06

CRANKPIN O. D.

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

30.00 29.94

dW177

33.00 32.94

dW188

36.00 35.94

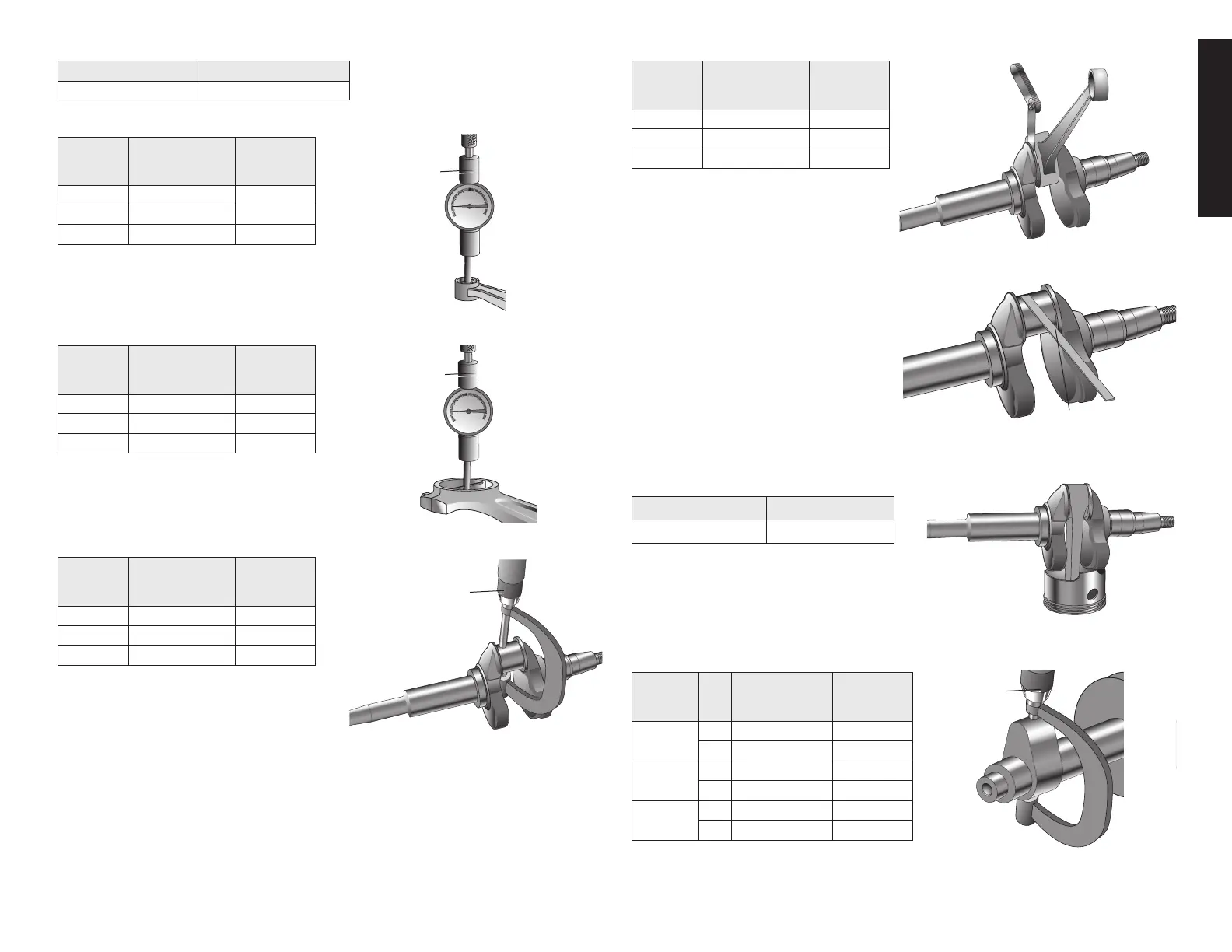

CONNECTING ROD BIG END SIDE CLEARANCE

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

0.95~1.45 1.85

dW177

0.55~1.25 1.65

dW188

0.55~1.25 1.65

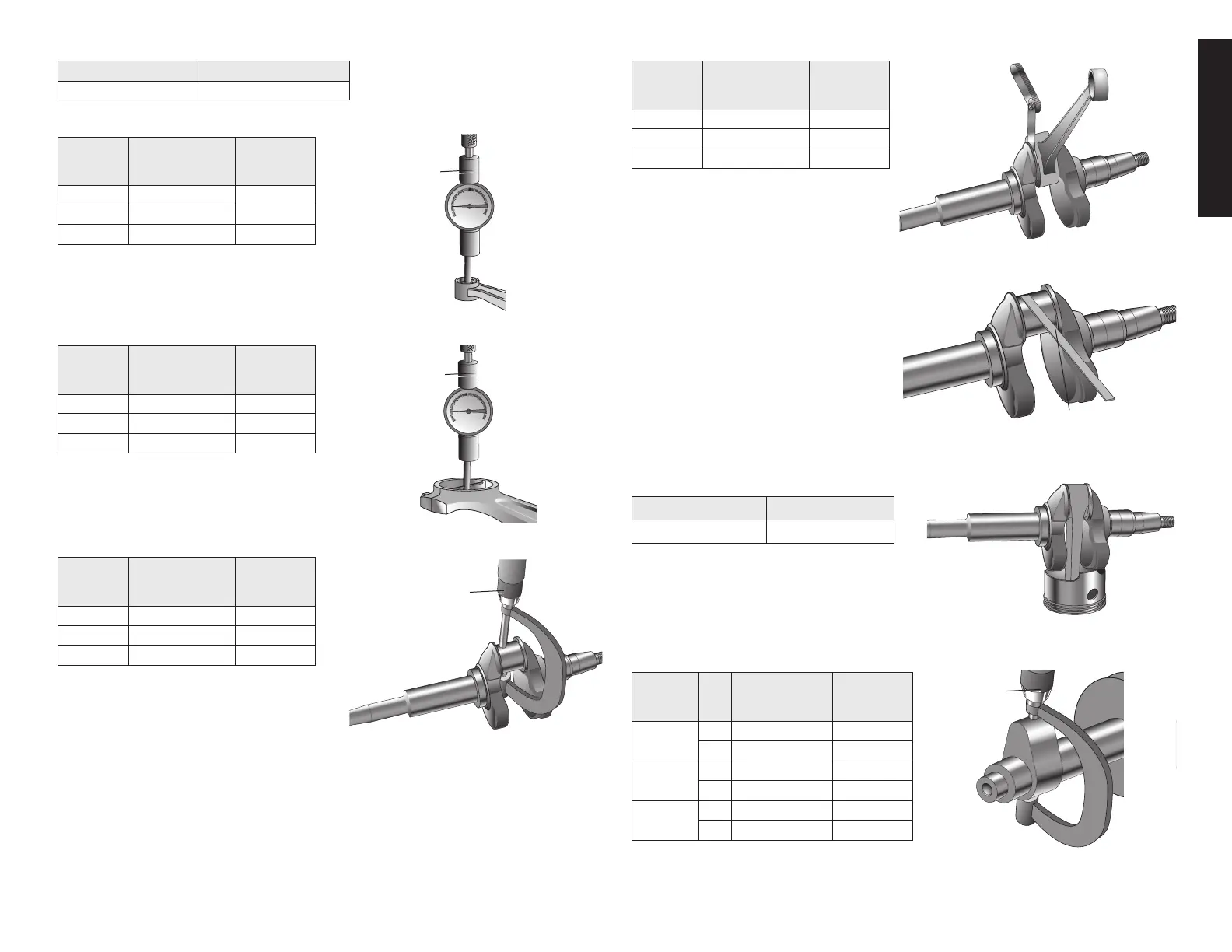

CONNECTING ROD BIG END OIL CLEARANCE

1.Clean all oil from the crank pin and

PLASTIGAUGE

connecting rod big end surfaces.

2. Place a piece of plastigauge on the

crankpin.

3. Install the connecting rod and cap.

4.Tightentheboltsandtorqueto12N•m

|(1.2Kg-m,9ft.-lbs.).

NOTE:Donotrotatethecrankshaftwiththe

plastigauge in place.

5. Remove the connecting rod and measure

the plastigauge.

STANDARD SERVICE LIMIT

0.04

~

.066 0.12

6. If the clearance exceeds the service limit,

replacetheconnectingrodandrecheckthe

clearance.

CAMSHAFT CAM HEIGHT

MODEL

STANDARD

(MM)

SERVICE

LIMIT

(MM)

dW168

IN

27.700 27.45

EX

27.747 27.50

dW177

IN

31.716 31.35

EX

31.754 31.35

dW188

IN

32.585 32.25

EX

32.068 31.80

MICROMETER

MICROMETER

DIAL INDICATOR

BORE GAUGE

DIAL INDICATOR

BORE GAUGE

Loading...

Loading...