41

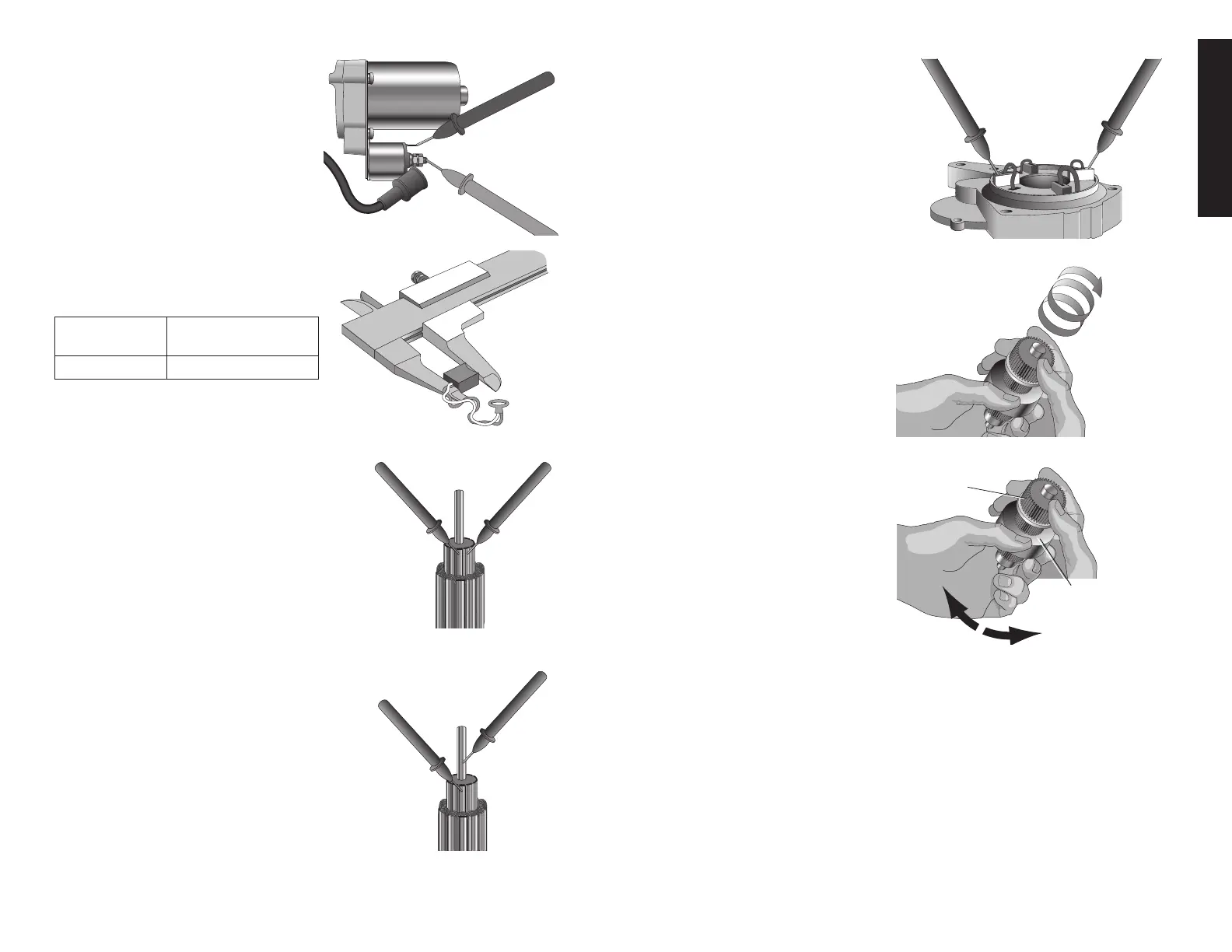

STARTER SOLENOID

Connect a 12V battery between the starter

terminal andthesolenoidbody and check

for continuity between terminals.

NOTE: Continuity should exist when the

battery is connected and not exist when the

battery is disconnected.

BRUSH LENGTH

Measure the brush length:

Replace the brush if the brush length is less

than service limit.

STANDARD

(MM)

SERVICE LIMIT (MM)

10 5.5

ARMATURE

Continuity check: commutator segments

Checkthecontinuitybetweenthesegments.

If an open circuit (no continuity) exists

between any two segments, replace the

armature.

Continuity check: commutator to shaft

Checkthe continuity between commutator

and the armature shaft. If continuity exists

between any of the commutator segments

and the armature shaft, replace the arma-

ture shaft.

BRUSHES - CONTINUITY CHECK

Remove the armature and check for

continuity between the brushes. There

should be no continuity between the

brushes.

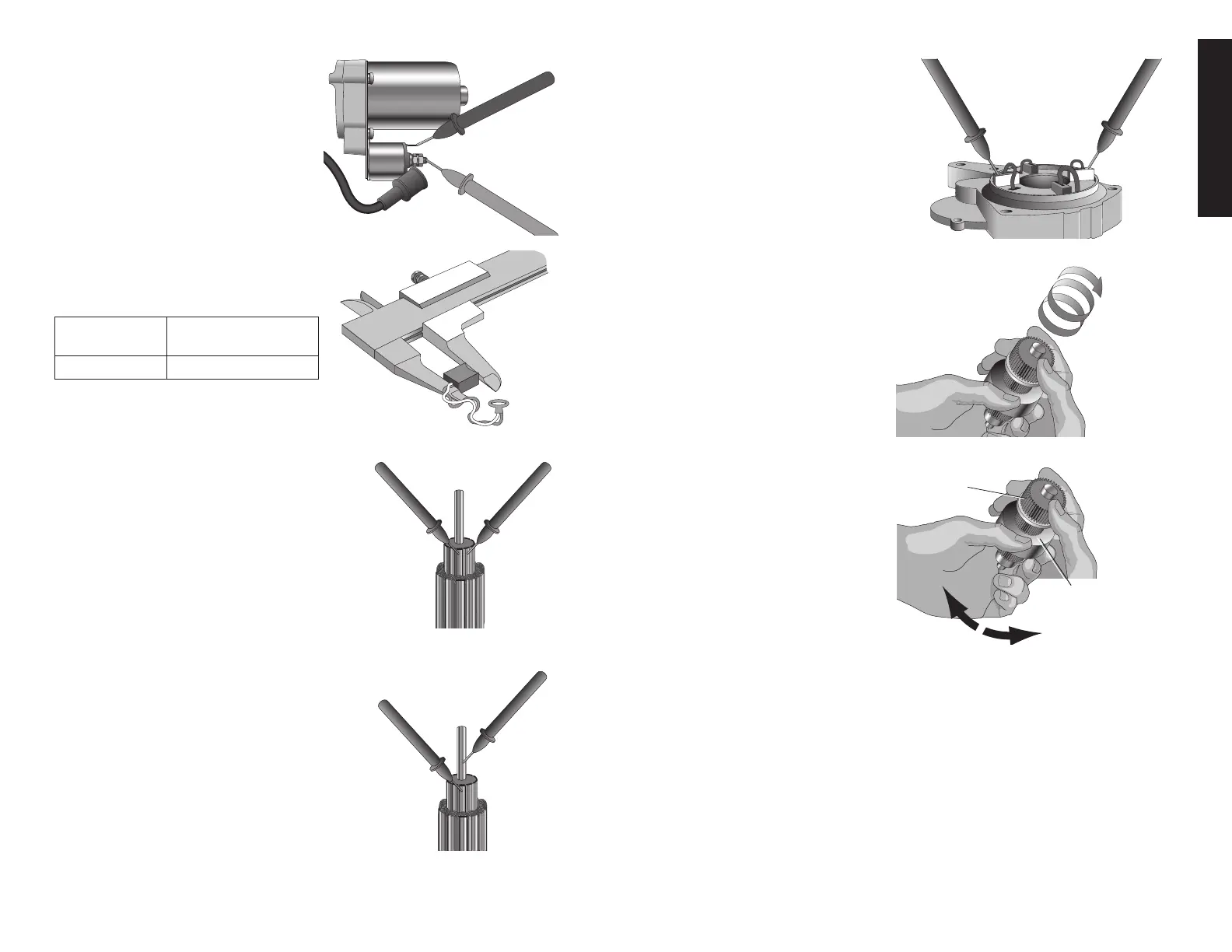

OVERRUNNING CLUTCH

1.Checktheoverrunningclutchforsmooth

axial movement. Apply oil or replace

the overrunning clutch, if necessary.

2.Checkthereductiongearmovementby

U6

E7

holdingthepiniongear(E7)and turn-

ingthereductiongear(U6).Thereduc-

tiongearshouldturncounterclockwise

freelyandshouldnotturnclockwise.

3.Checkthepiniongearforwearordam-

age and replace if necessary.

NOTE: If the pinion gear is worn or dam-

aged the flywheel ring gear must be

inspected.

Loading...

Loading...