48

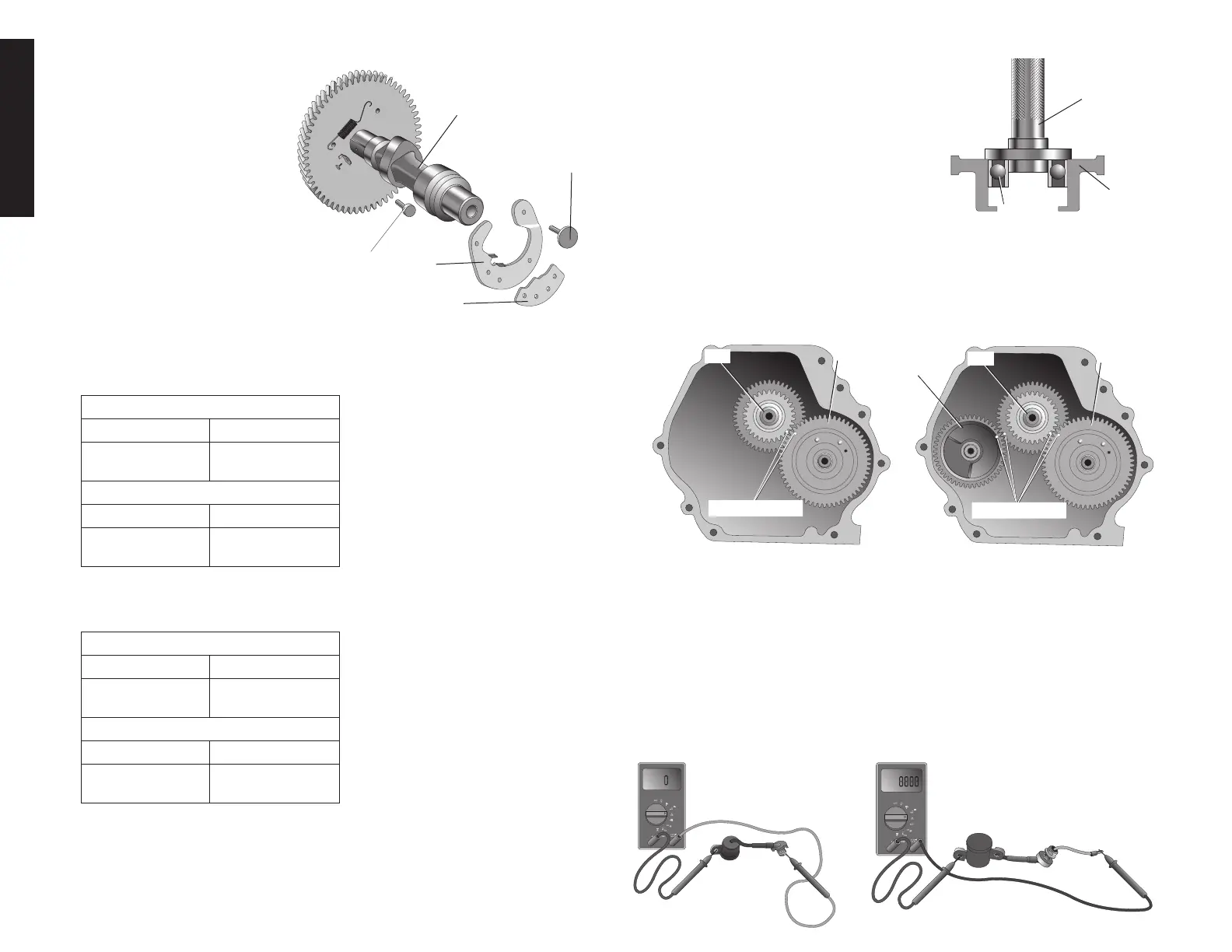

Crankshaft Bearing

Use a hydraulic press and driver with a diameter

DRIVER

X8

W9

larger than crankcase cover (X8) opening to

press the new bearing (W9) onto the crank-

shaft.

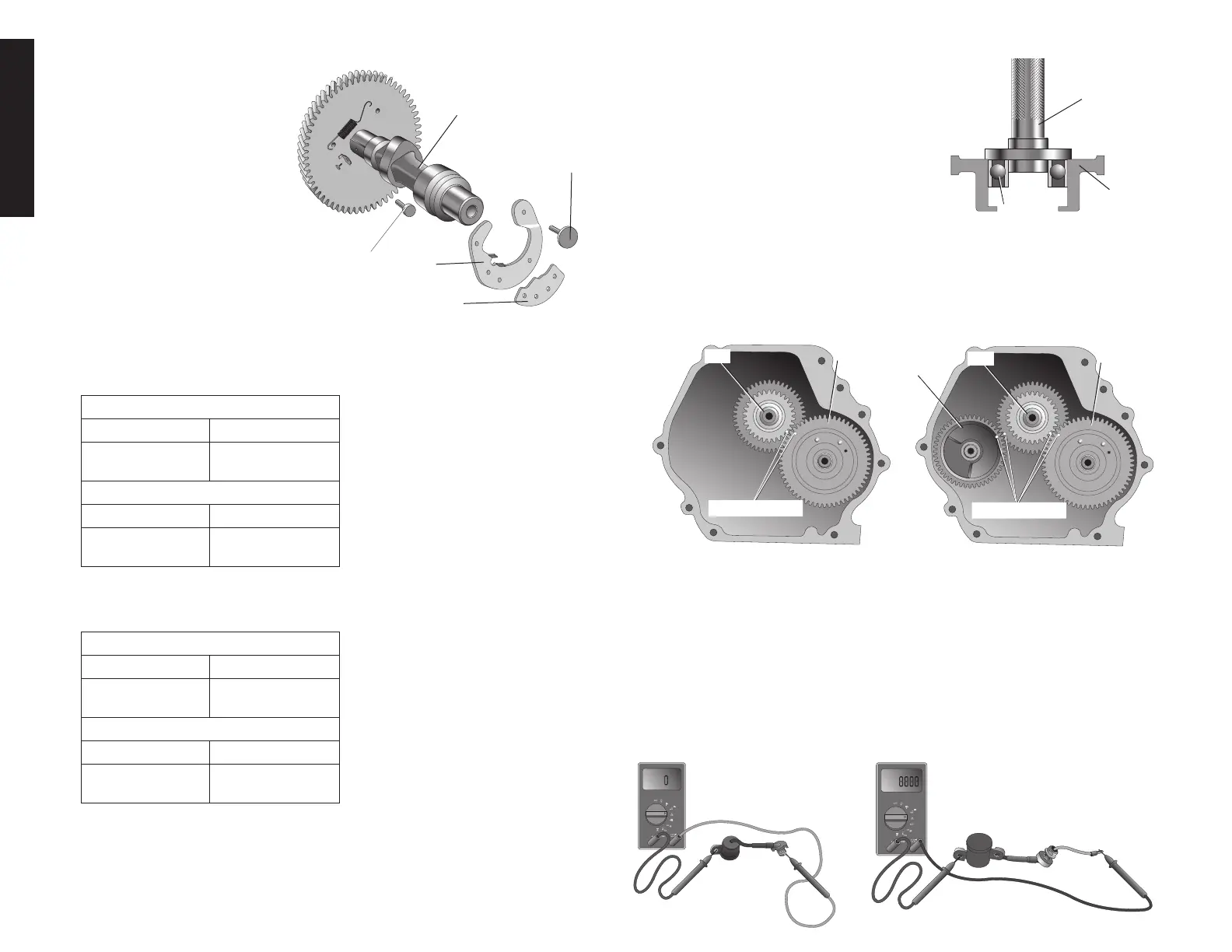

Timing Mark Alignment

NOTE: Balancer gear equipped on DW188F engines only, for DW168F and DW177F

engines proceed to step 2.

1.Withcrankshaft(X9)installedincrankcaseinstallbalancer(A10).NOTE:Alignmarks

onbalancerandbalancerdrivegearofcrankshaft.

2.Install the camshaft aligning marks on camshaft (Y9) with those on timing gear of

crankshaft.

Y9

X9

ALIGN MARKS

DW188F

Y9

X9

ALIGN MARKS

DW168F, DW177F

X10

OIL LEVEL SWITCH (DW177, DW188)

1. With the switch in the normal upright orientation test the continuity between the yellow

lead and the face of the brass ground connector as show. The ohm meter should read

approximately zero resistance.

2. Hold the switch upside down to simulate the float’s position in the crankcase when it is

filled with oil. Test the continuity in the same way between the face of the brass ground

connector and the yellow lead. The ohm meter should read approximately infinite

resistance.

3. If either test yields an incorrect reading replace the low oil shutdown unit.

Y9. Camshaft

Y9

C10

F10

E10

D10

C10. Reducer pin

E10. Flyingblock

D10. Matchingblock

F10. Flyingblockpin

REASSEMBLY

Timing Gear

Usetheoldgearasreferenceandmakeamarkatthesamepositiononthenewgear.

Useahydraulicpress,driverandattachmentI.D.(specialtool)topressthenewgearonto

thecrankshaft.

DW168

Driver 40 mm I.D. 07746 – 0030100

Attachment,

25 mm I.D.

07746 – 0030200

DW177 and DW188

Driver 40 mm I.D. 07746 – 0030100

Attachment,

30 mm I.D.

07746 – 0030300

Governor Drive Gear

Useahydraulicpress,driverandattachmentI.D.(specialtool)topressthenewgovernor

drivegearontothecrankshaft.

DW168

Driver 40 mm I.D. 07746 – 0030100

Attachment,

30 mm I.D.

07746 – 0030300

DW177 and DW188

Driver 40 mm I.D. 07746 – 0030100

Attachment,

35 mm I.D.

07746 – 0030400

Loading...

Loading...