16

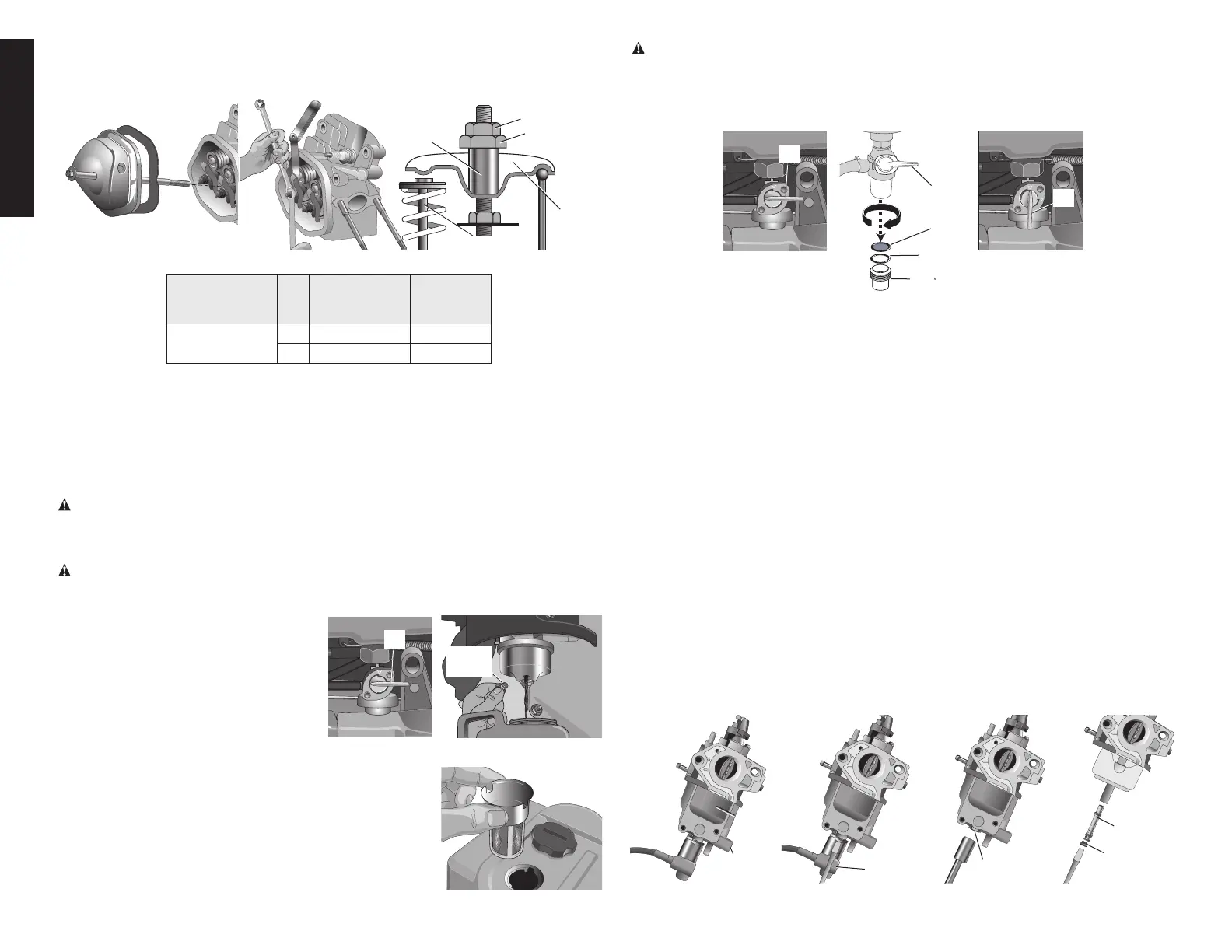

2.Set the piston in the top dead center position of its compression stroke.

NOTE:bothrockerarms(

P7,K8) will have the largest gap with each valve (U7,V7,P8,Q8).

3.Insertafeelergaugebetweentherockerarmandvalvetomeasurevalveclearance.

R7, M8

S7, N8

P7, K8

R10

U7, V7, P8, Q8

Standard

(mm)

Service

Limit

(mm)

VALVE

CLEARANCE

IN

0.10~0.15 -

EX

0.20~0.25 -

4.Adjustrocker armpivot(R7,M8) by loosening the rocker armlocknut (S7, N8)and

adjustthepivotlocknut(R10)untiltheclearanceiscorrect.Whenclearanceiscorrect

tightentherockerarmlocknut.

5.Checktheclearanceagainwithnutstightened.

IMPORTANT: If the engine does not start, is hard to start or is performing poorly ensure

fuelsystemiscleanandfueltankcontainsfreshgasolinebeforetroubleshooting.

WARNING: Risk of explosion.

Spilled gas o line and it’s vapors can be come ignited from

sparks from smoking products, electrical arcing, exhaust, flame, gas es and hot engine com-

ponents such as the muffler.

Make sure there are no sources of ignition, such as smoking

products near servicing location. Wipe any fuel spillage from engine.

WARNING: Hot surfaces. Risk of burn. Engine and surrounding parts are very hot, do

not touch. Allow engine to cool prior to servicing.

DRAIN CARBURETOR

1.Placethefuelshutoffvalve(A,ifequipped)

A

B2, K2,

F3

intheclosed(horizontal) positionas

shown.

2. Place an

OSHA-ap proved con tain er

suitable for fuel under the carburetor

bowl.

NOTE:

Using a funnel will allow

the fuel to flow into the container with

less spillage.

3. Remove the carburetor bowl drain bolt (B2,K2,F3).

4. Fuel will drain from carburetor bowl.

5. Remove the carburetor bowl and clean it in nonflammable

or high flash point solvent.

CLEANING DEBRIS SCREEN (IF EQUIPPED)

1. Remove fuel cap.

2. Remove debris screen.

3.

Clean debris screen. Use compressed air to blow off

debris.

WARNING: When using compressed air, user always must wear eye protection that

conforms to ANSI Z87.1. (CAN/CSA Z94.3).

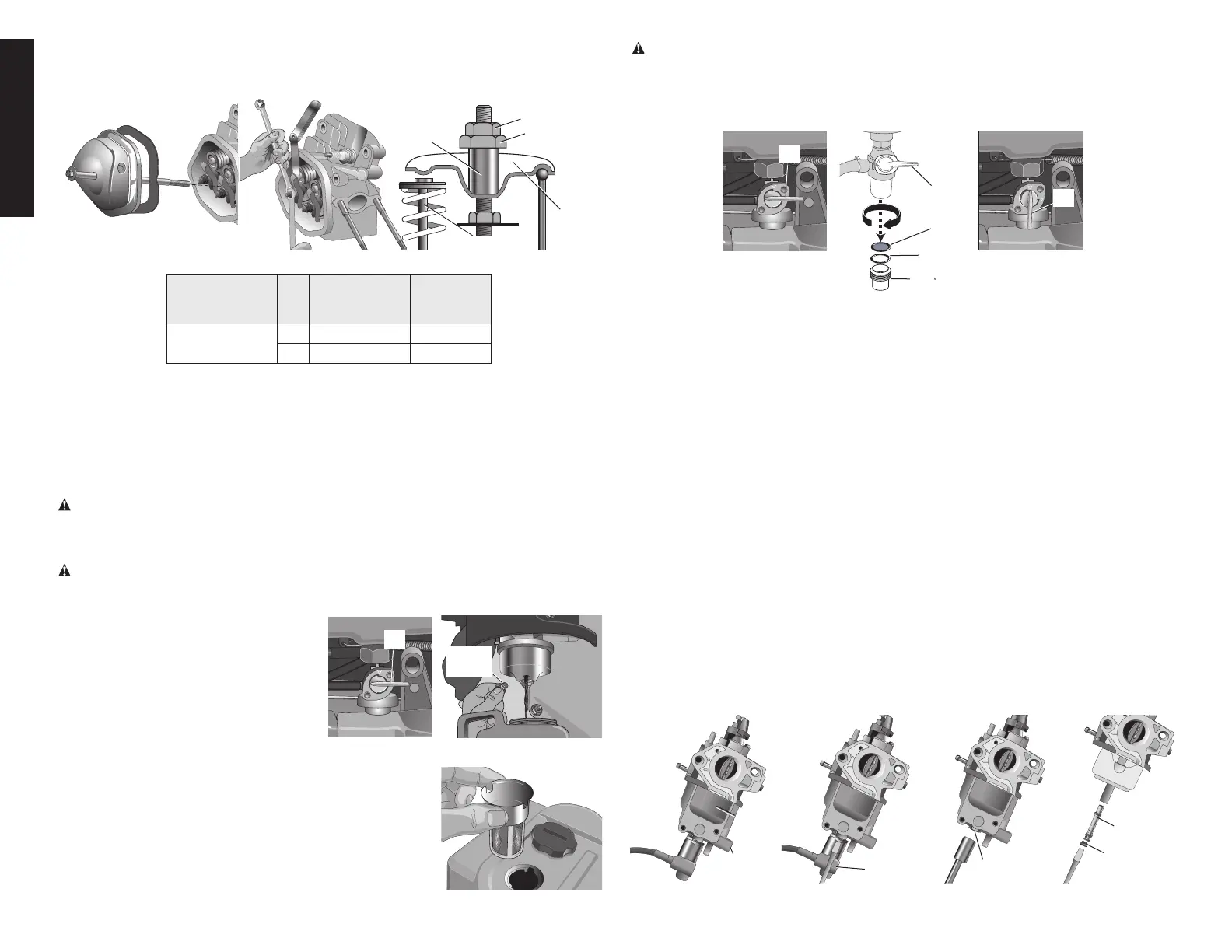

FUEL SEDIMENT CUP CLEANING (IF EQUIPPED)

1.Place the fuel shut off valve (A, if equipped) in the closed (horizontal) position as

shown.

A

B

A

C

D

A

2.Removethesedimentcup(D)fromthefuelvalveonthebottomofthetank.

3.Cleanthesedimentcup,screen(C)andO-ring(B)innonflammableorhighflashpoint

solvent.

4.Drainandremovegastank,flushuntilclean.

5.Replaceorcleanfuelfilter.Fuelfiltermaybeinsidegastankwherefuelexitsoran

in line fuel filter may be on the fuel line. See

Service Bulletin

(SB06109)

REASSEMBLE

1. Reinstall O-ring, sediment cup, carburetor bowl, carburetor bowl drain bolt, debris

screen and fuel cap

2.Replaceinlinefilter(ifequipped).

3.Turnthefuelshut-offvalve(A,ifequipped)totheopen(vertical)positionandcheckfor

fuelleaks.

High Altitude Modification should only be made to engines operating at above

5,000ft.(1524m)foranextendedperiodasmanufacturedenginesaresuitableforopera-

tionupto5,000ft.(1524m)abovesealevel.NOTE: Reset to factory setting immediately

whenengineismovedtooperatebelow5,000ft.(1524m).Toreset,replacehighaltitude

main jet with low altitude main jet. If the engine is used at low altitudes after a carburetor

modification, the carburetor may cause the engine to overheat and result in serious engine

damage.

1. Set the fuel valve in the off position. Remove the carburetor drain bolt (

B2,K2,F3) from

the carburetor bowl (

E3,J2) and allow fuel to drain into a suitable container.

2. Remove the fuel cutoff solenoid (

D3, if equipped) from the carburetor bowl using a

Phillips screwdriver.

B2,

K2, F3

V3, L2

X2

D3

I4

E3, J2

3. Remove the carburetor bowl (E3,J2)andretainingbolt(V3,L2)witha14mmsocket.

Loading...

Loading...