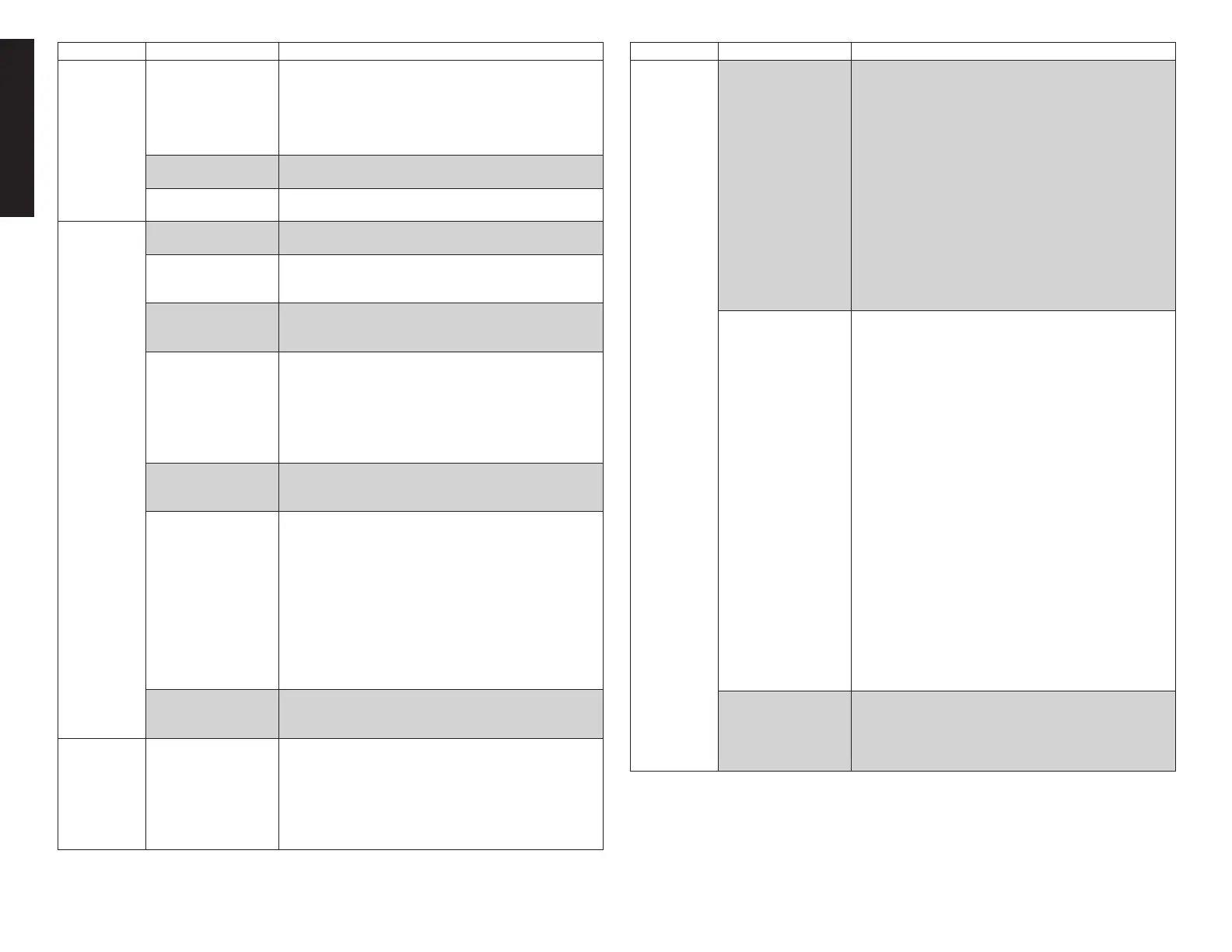

18

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will

not start,

stay running

or only runs

whenchoked

(continued)

17.Vacuumleakat

carburetor

Ensure the evaporative system hose from the

charcoal canister is connected firmly to port

behind carburetor and other evaporative hoses

are connected firmly. Ensure carburetor is tightly

secured to engine by the two mounting nuts inside

air cleaner

18. No or low

compression

Refer to Compression Test under Perform Test

Checks.

19. Dirty air filter Ensureaircleaneriscleanandnotblockingairfrom

entering carburetor. Clean if necessary.

Engine will

not turn

over, engine

seized

1. Battery is dead

(Electricstart)

Tryfullychargedbattery.Replacebatterypackif

needed.

2. Recoil pull

starter rope

broken

Replace pull start rope. Refer to Recoil Starter/

Assemble Recoil Starter under Breakdowns.

3. Recoil pull start

not engaging

engine

Remove recoil assembly. Repair or replace as nec-

essary. Refer to Recoil Starter/Assemble Recoil

Starter under Breakdowns.

4. Cylinder filled

with gas.

Removesparkplugandtipenginemomentarily.If

gas pours out hole, carburetor float bowl needle is

stuckopen.Cleanorreplacecarburetor.Referto

Carburetor under Breakdowns for cleaning instruc-

tions.

NOTE: When transporting unit fuel valve must be in

OFF position, if not flooding will occur."

5. Electric starter

motor faulty

Refer to Start Mechanism under Perform Test

Checks and Starter Motor under Breakdowns for

checks.

6. Excessive

carbon buildup

in head. Engine

was possibly run

withchokein

closed or partially

closed position

instead of open.

Ensurechokemechanismoperates

correctly.

Withthechokeinthefullyopenpositionandthe

enginerunning,thechokeplateatentranceofthe

carburetor should be fully open.

Onleverchokesmovetheleverallthewaytothe

right

Replacechokemechanismifchokedoesnot

operate in this way or is damaged. Test and verify

compression is correct. Refer to Compression Test

under Perform Test Checks.

7. Internal part

failure

Withsparkplugremoved,rotateengineshaftby

handtoseeifitrotatessmoothly.Ifstilllockedup,

removecrankcasecoveranddeterminecause.

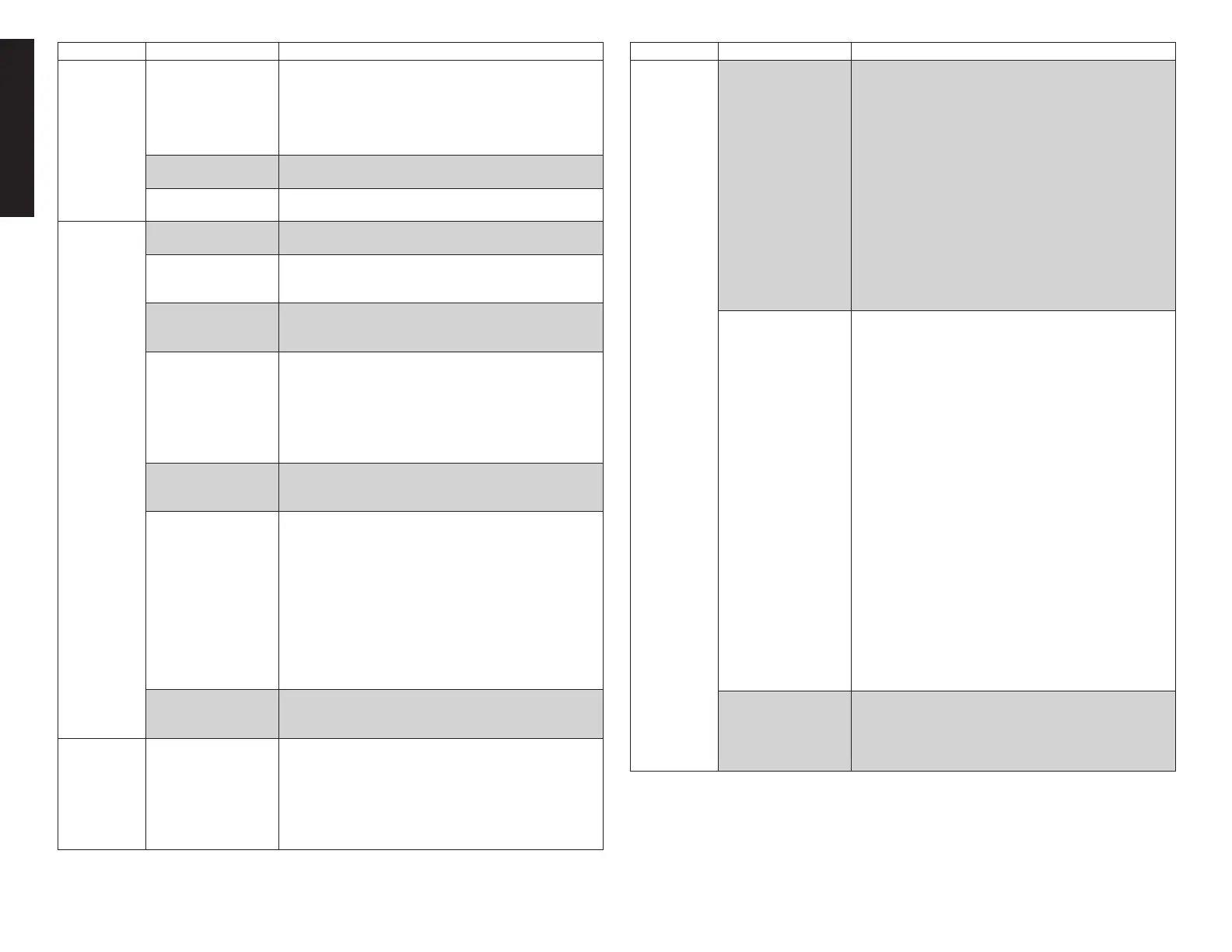

Poor

performance,

low power,

running

too fast,

Backfiring

often

1. Fuelquality

issue or

restriction

Refer to Engine will not start, stay running or

only runs when choked steps 5,6,12 & 13 under

Starting Problem/Engine under Troubleshooting.

PROBLEM POSSIBLE CAUSE SOLUTION

Poor

performance,

low power,

running

too fast,

Backfiring

often

(continued)

2. Sparkarrestor

dirty or clogged

Cleansparkarrestor,refertoSpark Arrestor under

Maintenance.Runenginebrieflywithoutspark

arrestor to verify that was the cause. Reassemble

sparkarrestortomuffler.Ifscreenisdamaged

replacesparkarrestorifscreenisdamaged.

IMPORTANT:Theseproductsareequippedwith

spark-arrestingmufflers.Itislegallyrequiredin

the state of California. It is a violation of California

statutes section 130050 and/or sec tions 4442 and

4443 of the California Public Re sourc es Code,

unlesstheengineisequippedwithasparkarrester,

as defined in section 4442, and maintained in ef fec-

tiveworkingorder.Sparkarrestersarealsorequired

on some U.S. For est Service land and may also be

legallyrequiredunderotherstatutesandordinanc-

es.

3. Worn governor

arm rivet joint

Worn carburetor

throttle actuator,

Governor arm

slipping on shaft,

Throttlelinkages

bent

High speed

screw has been

tampered with

Ifengineisrunningover4000rpm(67Hz),first

ensurealllinkagescontrollingthethrottleposition

actuate freely without binding over full travel. NOTE:

Comparingtheoldgovernorlinkagetoanew

replacementgovernorlinkagemayhelptodeter-

mine if the components in the system are worn or

damaged.

• The riveted joint in governor arm must pivot

freely but not be loose and sloppy.

• Ifthehighspeedadjustingscrewhasbeentam-

pered with it can be readjusted, refer to Speed/

Governor Adjustments under Perform Test

Checks. HOWEVER, if the root cause of the high

speed is due to the governor arm slipping on the

governor shaft, adjusting the speed will give a

false indication of being correct. The speed will

beokuntilputunderaload,theenginewilldroop

or bog down. After adjusting the speed, the

unitmustbetestedusingaloadbanktesterby

gradually applying full rated load. If speed drops

more that 3 Hz, the governor arm has slipped on

the shaft and needs to be reset. To reset gover-

nor arm, refer to Speed/Governor Adjustments

under Perform Test Checks.

4. Backfiringoften

or air filter

melted, Ignition

coil could be

faulty

Replace ignition coil. NOTE: Coil resistance can

measureokandstillbefaulty.Itisbesttoreplace

coil in this case.

Loading...

Loading...