WARNING_ad

Discharge lines made from non-conducting material can build up

static charge.

Static discharge can cause explosion of potentially existing oil

mist.

The discharge line must be made of conducting material or provi

-

sions must be made against static discharge.

Electrical Connection / Controls

●

Make sure that the stipulations acc. to the EMC-Directive

89/336/EEC and Low-Voltage-Directive 73/23/EEC as well as the

EN-standards, electrical and occupational safety directives and the

local or national regulations, respectively, are complied with (this is

in the responsibility of the designer of the machinery into which

the vacuum pump is to be incorporated; Ú note in the EC-Decla

-

ration of Conformity).

●

Make sure that the power supply for the drive motor is compatible

with the data on the nameplate of the drive motor (400)

●

Make sure that an overload protection according to EN 60204-1 is

provided for the drive motor

●

Make sure that the drive of the vacuum pump will not be affected

by electric or electromagnetic disturbance from the mains; if neces

-

sary seek advice from the Busch service

In case of mobile installation:

◆

Provide the electrical connection with grommets that serve as

strain-relief

Installation

Mounting

● Make sure that the à Installation Prerequisites are complied with

● Set down or mount the vacuum pump at its location

Connecting Electrically

WARNING_ab

Risk of electrical shock, risk of damage to equipment.

Electrical installation work must only be executed by qualified per

-

sonnel that knows and observes the following regulations:

- IEC 364 or CENELEC HD 384 or DIN VDE 0100, respectively,

- IEC-Report 664 or DIN VDE 0110,

- BGV A2 (VBG 4) or corresponding national accident prevention

regulation.

CAUTION_a

The connection schemes given below are typical. Depending on the

specific order or for certain markets deviating connection schemes

may apply.

Risk of damage to the drive motor!

The inside of the terminal box shall be checked for drive motor con

-

nection instructions/schemes.

●

Electrically connect the drive motor (400)

●

Connect the protective earth conductor

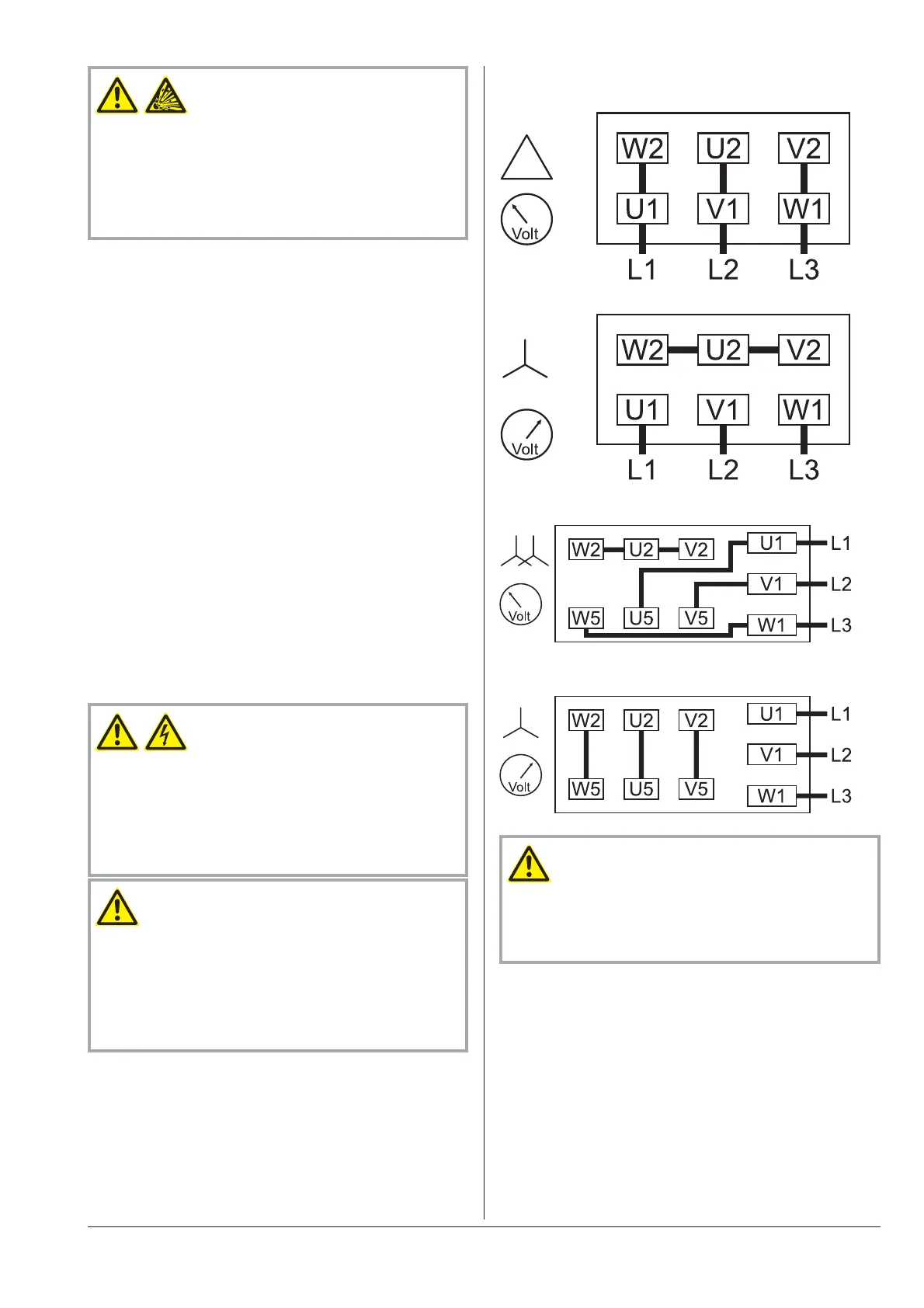

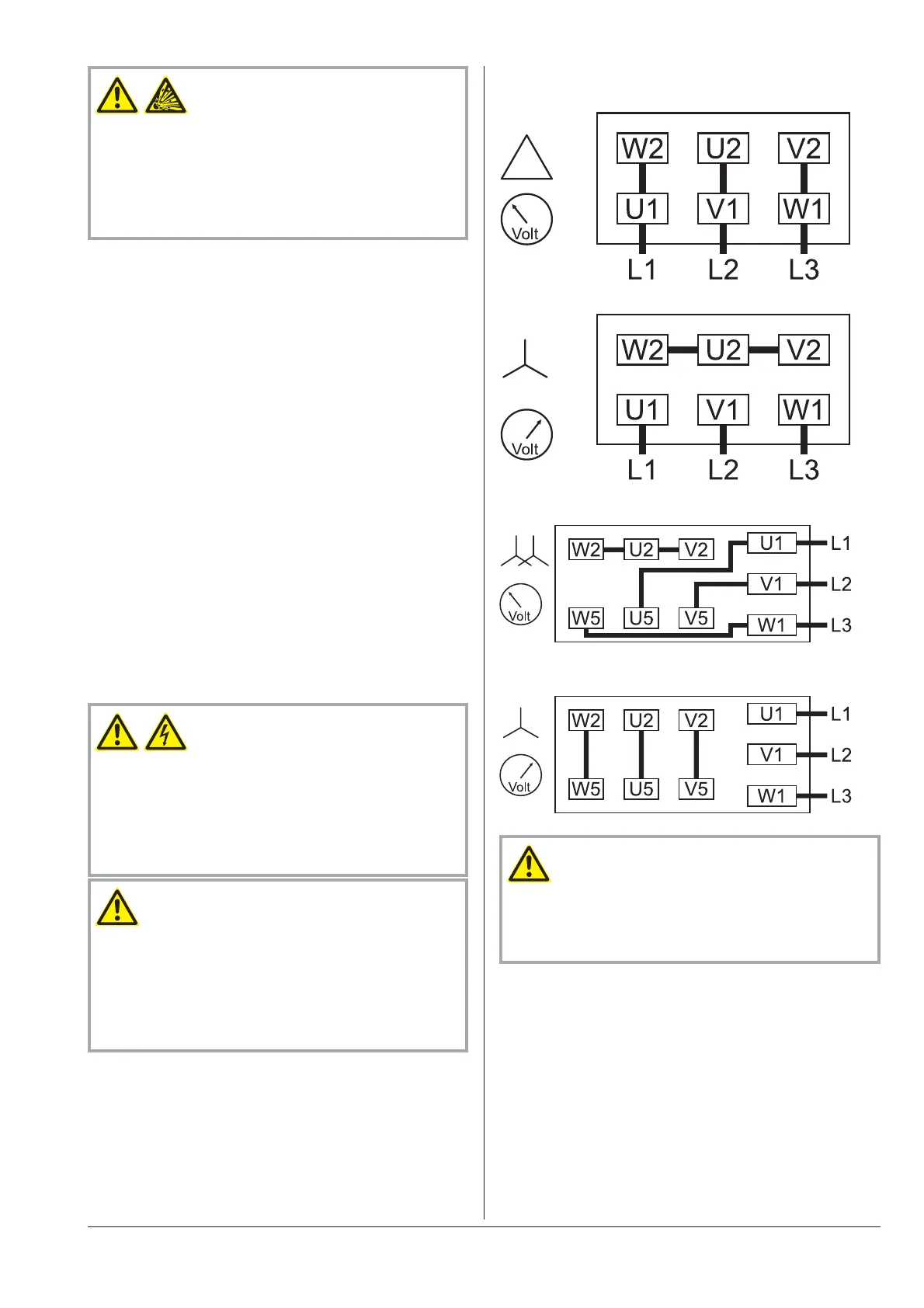

Connection Scheme Three-Phase Motor

Delta connection (low voltage):

Star connection (high voltage):

Double star connection, multi-voltage motor (low voltage):

Star connection, multi-voltage motor (high voltage):

CAUTION_a

Operation in the wrong direction of rotation can destroy the

vacuum pump in short time.

Prior to starting-up it must be made sure that the vacuum pump is

operated in the proper direction.

Version with three-phase motor:

◆

Determine the intended direction of rotation with the arrow (a,

431) (stuck on or cast)

◆

“Bump” the drive motor (400)

◆

Watch the fan wheel of the drive motor (400) and determine

the direction of rotation just before the fan wheel stops

If the rotation must be changed:

◆

Switch any two of the drive motor wires (three-phase motor)

Connecting Lines/Pipes

In case the suction line is equipped with a shut-off valve:

◆

Connect the suction line

RA 0025 - 0040 F Installation and Commissioning

0870139077 / 051214 page 7

Loading...

Loading...