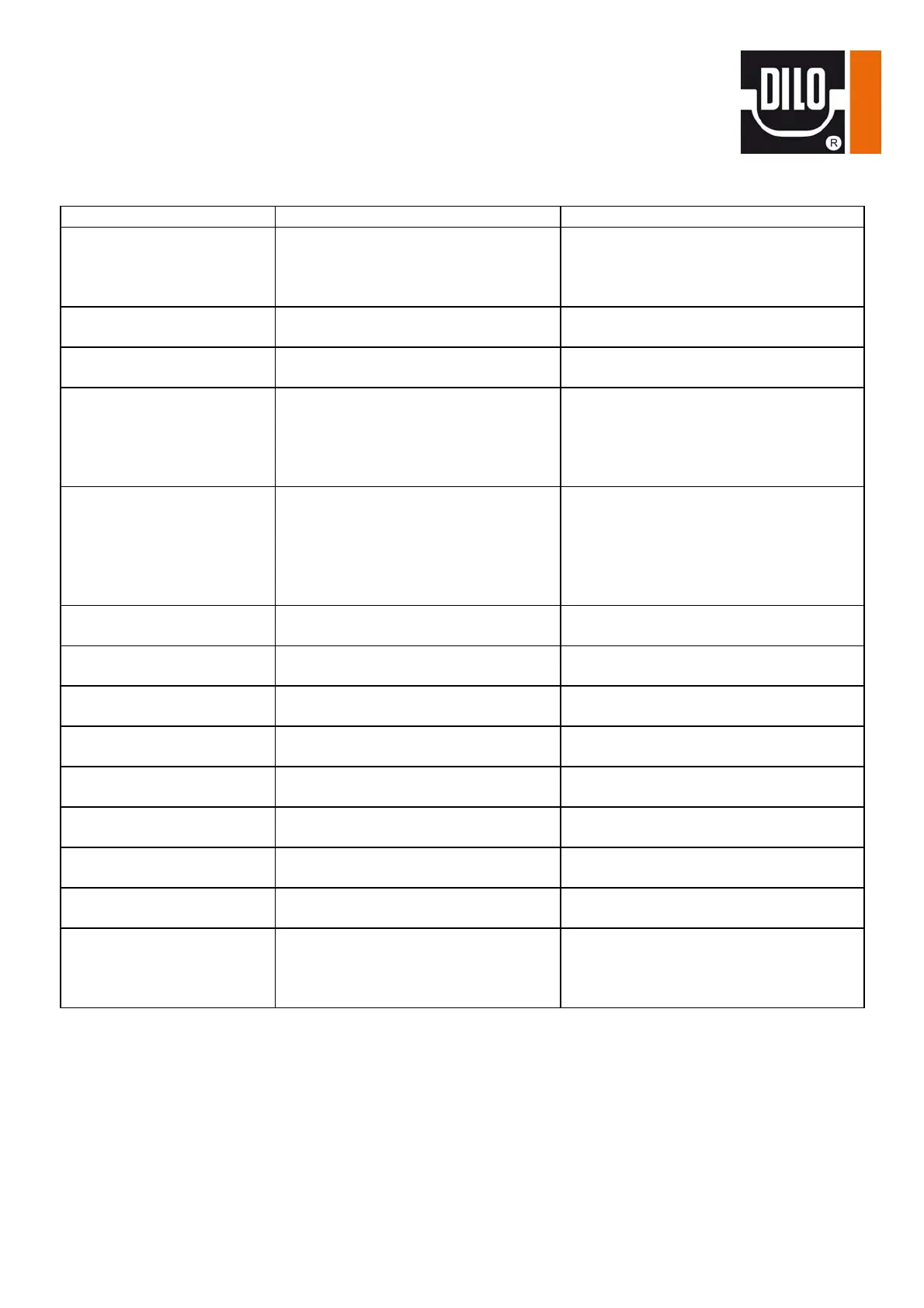

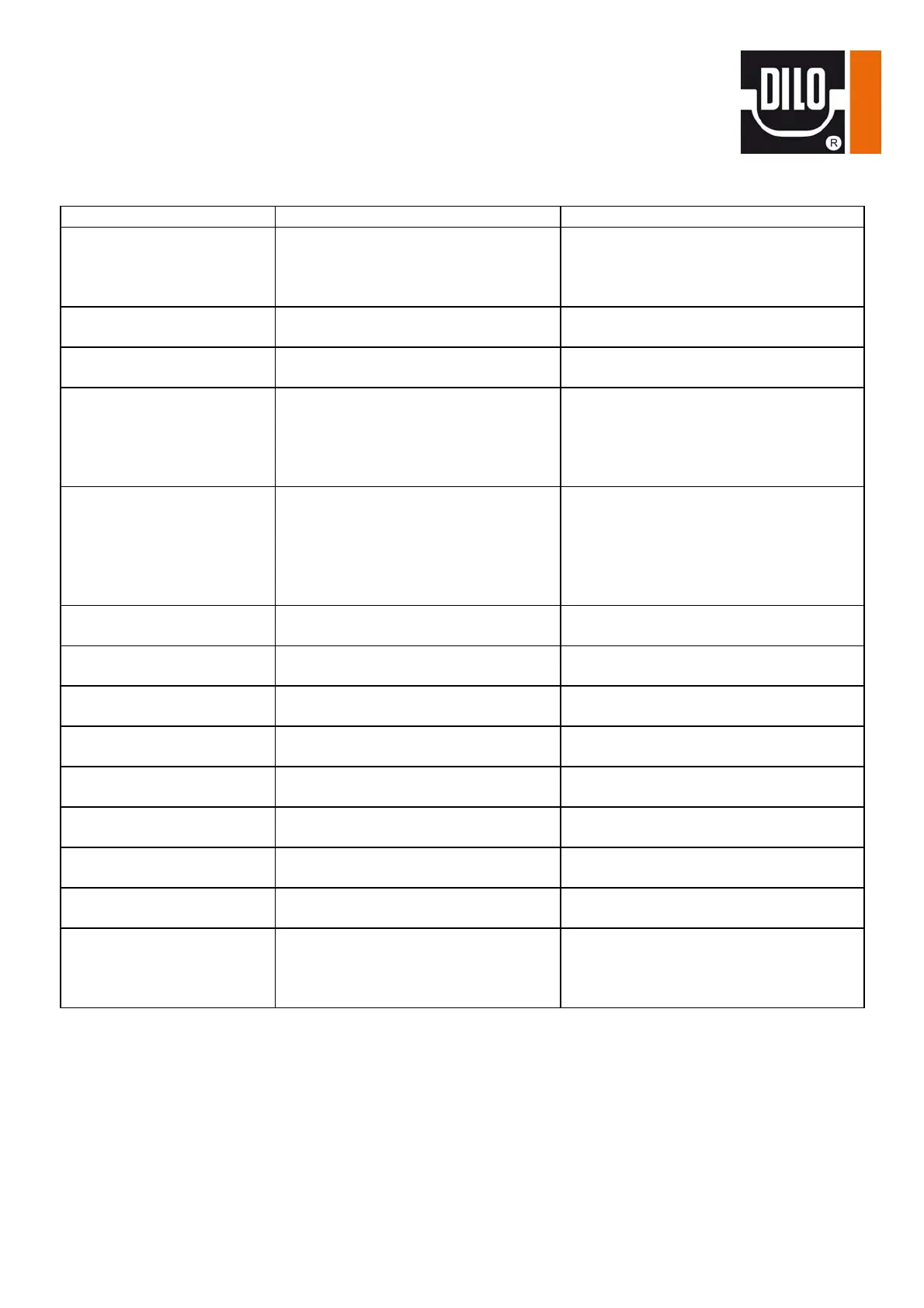

Fault correction

www.dilo-gmbh.com | 0800.bae

List of failure on the operating panel:

Error message Possible cause of error Correction

Incorrect direction of

rotation

Phase failure,

incorrect direction of rotation

Defective phase sequence relay

Check the power supply.

Change the position of the reversing

switch

Exchange the phase sequence relay

Vacuum compressor

pressure too high

Pressure upstream or downstream

from the vacuum pump too high

Reduce pressure as described under

item “Recovery of SF

6

–gas“

Vacuum pump pressure

too high

Pressure upstream from the

vacuum pump too high

Reduce pressure as described under

item “Recovery of SF

6

–gas“

Compressor pressure too

high

Ball valve (valve) on the storage

tank is closed

Ball valve pos. 202 is closed

Solenoid valves downstream from

the compressor do not open

Check the ball valve (valve) on the

storage tank

Check the solenoid valves

Motor protection circuit

breaker / Thermistor

switched off

Overcurrent of a component

Due to excess temperature the

thermistor has switched off

(red LED in the Thermistor lights

up)

Check the motor protection circuit

breaker

Check the temperature of the

compressor and let the compressor

cool down if necessary.

Check the Thermistor.

Sensor pos.301

interrupted

Defective pressure sensor pos.301

Cable is not connected.

Check the pressure sensor pos. 301

Check the sensor connection.

Sensor pos.302

interrupted

Defective pressure sensor pos.302

Cable is not connected

Check the pressure sensor pos. 302

Check the sensor connection.

Sensor pos.304

interrupted

Defective pressure sensor pos.304

Cable is not connected.

Check the pressure sensor pos. 304

Check the sensor connection.

Sensor pos.305

interrupted

Defective pressure sensor pos.305

Cable is not connected.

Check the pressure sensor pos. 305

Check the sensor connection.

Sensor pos.306

interrupted

Defective pressure sensor pos.306

Cable is not connected.

Check the pressure sensor pos. 306

Check the sensor connection.

Sensor pos.603

interrupted

Defective pressure sensor pos.603

Cable is not connected.

Check the pressure sensor pos. 603

Check the sensor connection.

Sensor pos.604

interrupted

Defective pressure sensor pos.604

Cable is not connected.

Check the pressure sensor pos. 604

Check the sensor connection.

Bottle sensor interrupted Defective DMS measuring

transducer.

Exchange the DMS measuring

transducer.

Lack of gas Storage tank is empty

Storage pressure < 2bar

Ball valve on the storage tank is

closed

Check the pressure in the storage

tank (fill the storage tank)

Check the position of the ball valve

Loading...

Loading...