Maintenance and functional test

www.dilo-gmbh.com | 0900.bae

General operating instructions for hoses

1. Period of use for rubber hoses: 6 years (see DIN 20066)

The hoses used at service carts should be checked for tightness once a year. For this purpose the

following two tests should be carried out:

a) Pressure test

Connect the hose so that there is a pressure indication on the gauge. The hose must be pressurized.

Look at the gauge, no pressure drop should occur.

b) Vacuum test

Connect the hose to the vacuum pump. Interconnect suitable vacuum gauge. Produce vacuum. After

having switched off the vacuum pump, the vacuum indication should remain unchanged at constant

room temperature.

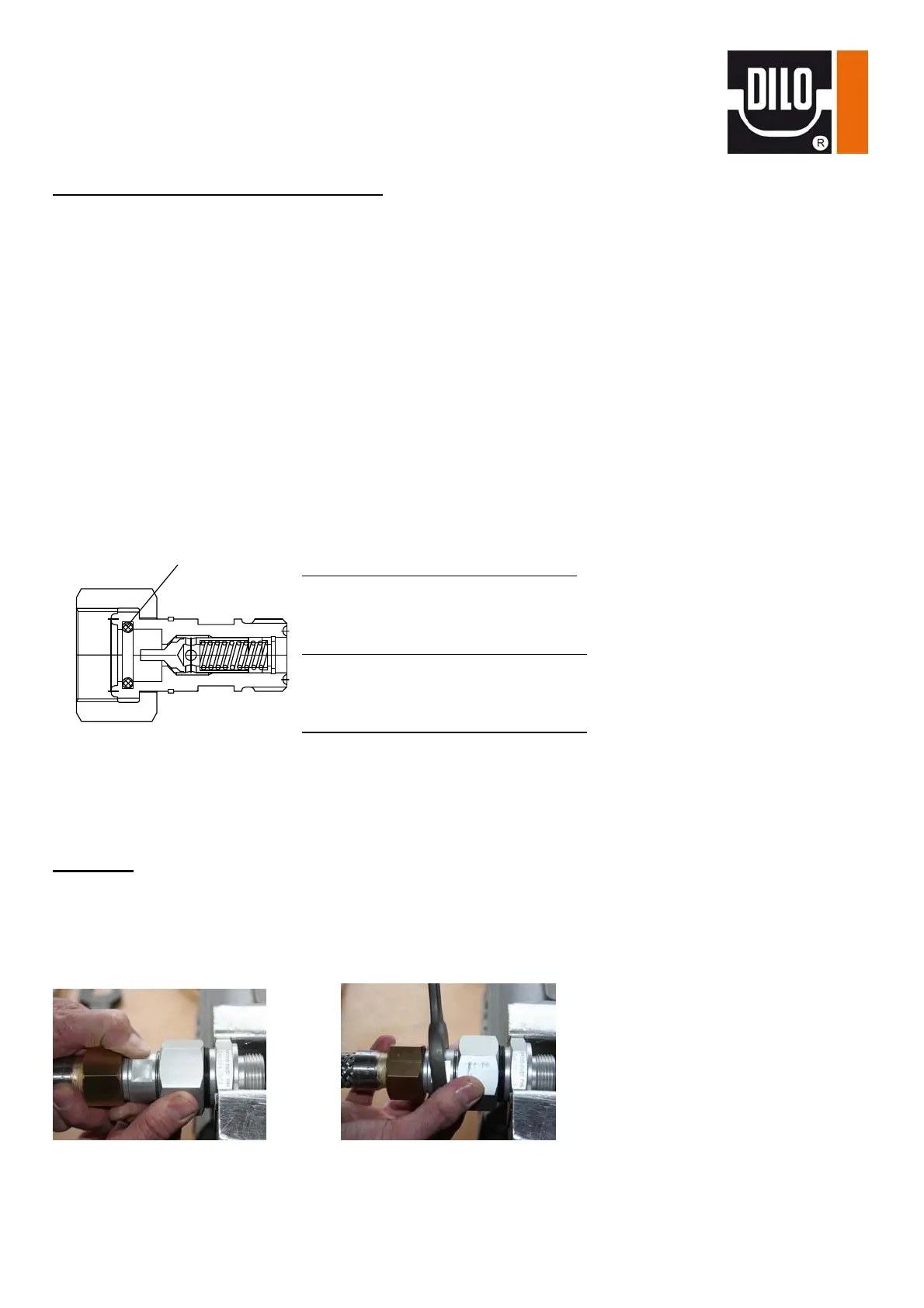

2. The DILO-coupling tongue parts DN8 and DN20 are equipped with an O-ring which is to provide an

external seal during the coupling process. As the O-ring is used for each coupling process and because

of abrasion, it should be replaced from time to time.

3.

O-ring for coupling tongue part DN8:

order no.: 05-0057-R024

dimension: ID 13.95 x W 2.62 EPDM

O-ring for coupling tongue part DN20:

order no.: 05-0057-R010

dimension: ID 20.29 x W 2.62 EPDM

O-ring for coupling tongue part DN40:

order no.: 05-0057-R141

dimension: ID 44.12 x W 2.62 EPDM

4. In order to protect the connecting hose and the piping system from contamination by decomposition

products, we recommend using a pre-filter unit.

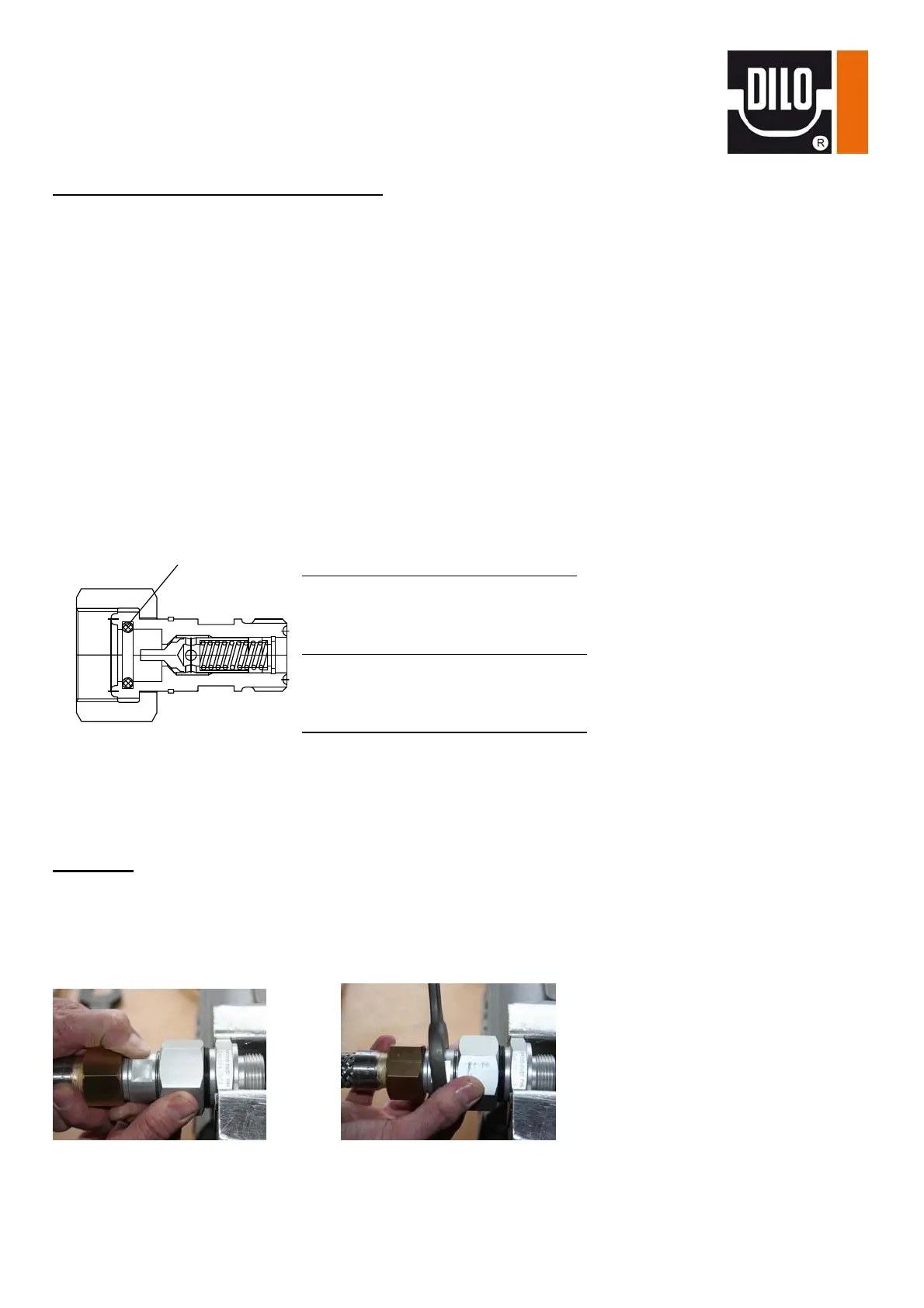

Attention:

When coupling it is absolutely necessary to use counteracting force on the coupling tongue part to avoid

“turning“ of the coupling body.

This can be done by hand or by using a wrench. Please see pictures.

o-ring

Loading...

Loading...