Dry filter revision | 3-899-R…

www.dilo-gmbh.com | C 1978-03 | Page 7 / 8

5. Exchange of the desiccative of the filter cartridge

Attention: When exchanging the used desiccative avoid any contact.

Do not blow up dust. Work in a well ventilated room or outdoors. Before opening the filter cartridge

corresponding protective measures have to be taken, see our working protection set 3-442.

Please observe:

The DILO-refilling device 3-834-R002 should be used for the exchange

of the used desiccative (to be ordered separately).

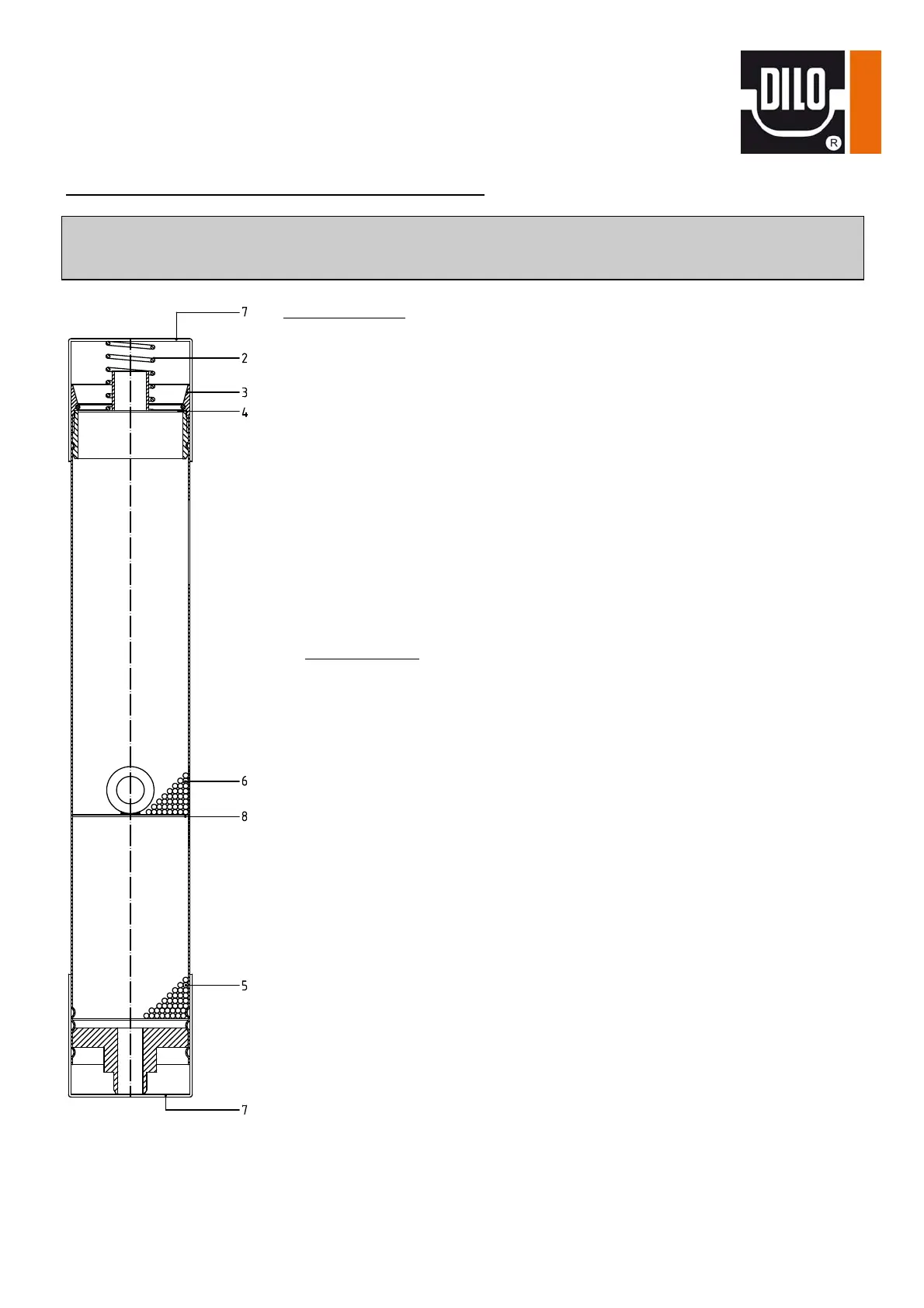

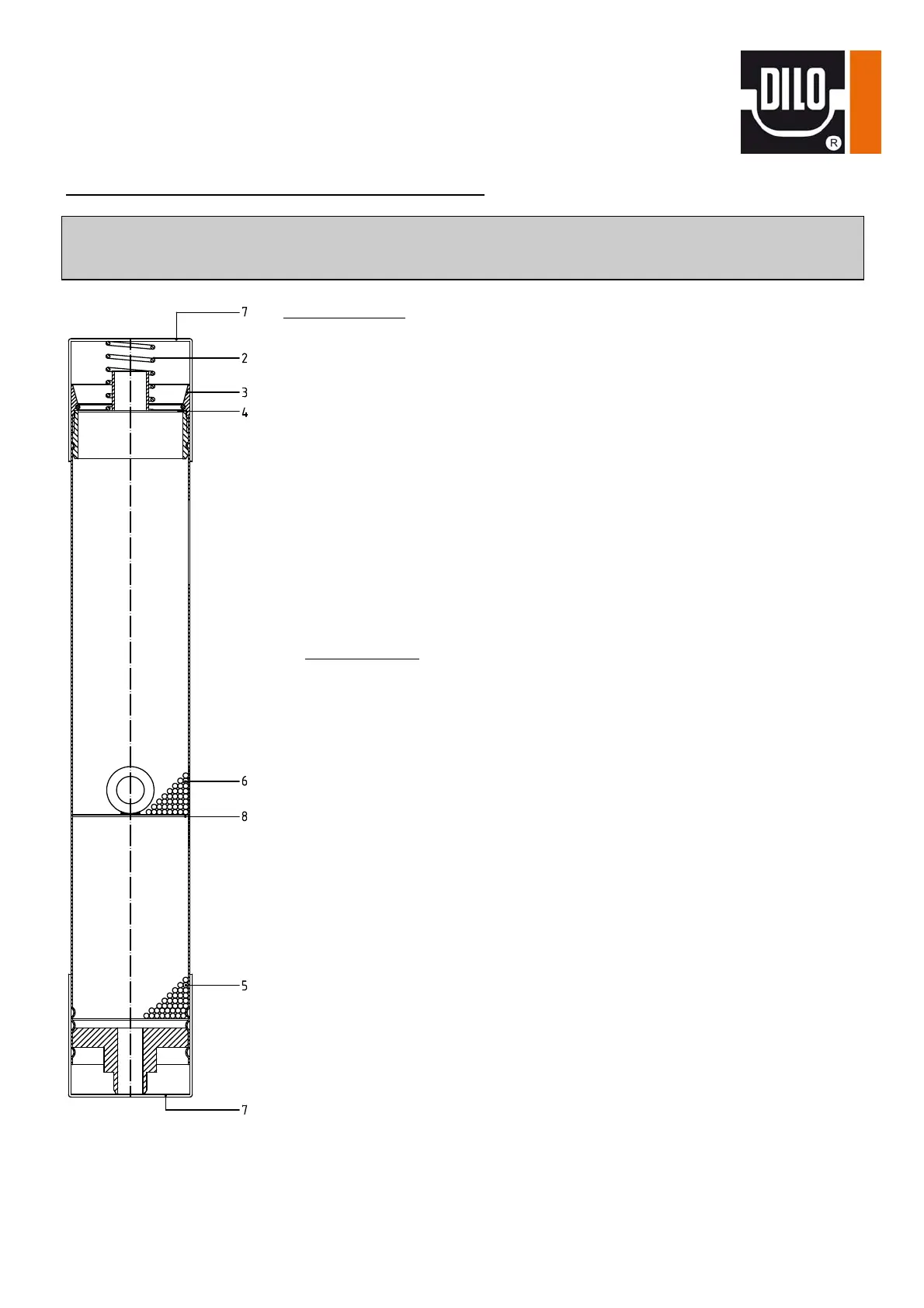

Remove the sealing caps (pos. 7).

Remove the spring (pos. 2).

Unscrew the threaded ring (pos. 3) by using a strap wrench

1-05-1196-R001 (to be ordered separately)

Remove the perforated plate (pos. 4).

Fill the desiccative into a plastic packing and seal it tightly. Observe that

for this the perforated plate (pos. 8) is removed and will be kept until

refilling.

Clean the interior space of the filter cartridge with a fibreless piece of

cloth.

Fill with new desiccative in a dry room. Dust abrasion and absorption of

moisture by ambient air are avoided if one lets flow N

2

with slight

overpressure (max. pe 0.5 bar) from the bottom through the filter

cartridge that is put upright during the filling process.

Filling process:

Fill 1/3 of the cartridge with molecular sieve (pos. 5). Compress the

desiccative by slightly knocking (rubber mallet) until it does no longer

sink.

Then insert the perforated plate (pos. 8).

Fill in aluminium oxide (pos. 6) until the top edge of the cartridge,

compress and refill until it does no longer sink.

(Desiccative - packed in tins - can be ordered under the following

order-no.: 3-899-07.)

Clean the thread (lubricate with the "Molykote" spray D-321R)

Put on the perforated plate (pos. 4) and screw on the threaded

ring (pos. 3).

Insert the spring (pos. 2).

If the installation into the dry filter is carried out later the sealing

caps (pos. 7) must be plugged on to avoid that ambient moisture is

absorbed.

Loading...

Loading...