24

2. Proceed as follows when it becomes necessary to

modify solid section sawing recommendations: (a)

Measure the thinnest stock section to be cut; (b)

Apply the corresponding percentage factor from

the following chart; (c) Use a high band speed, but

never exceed the maximum speed recommended

for stock sections of the same size.

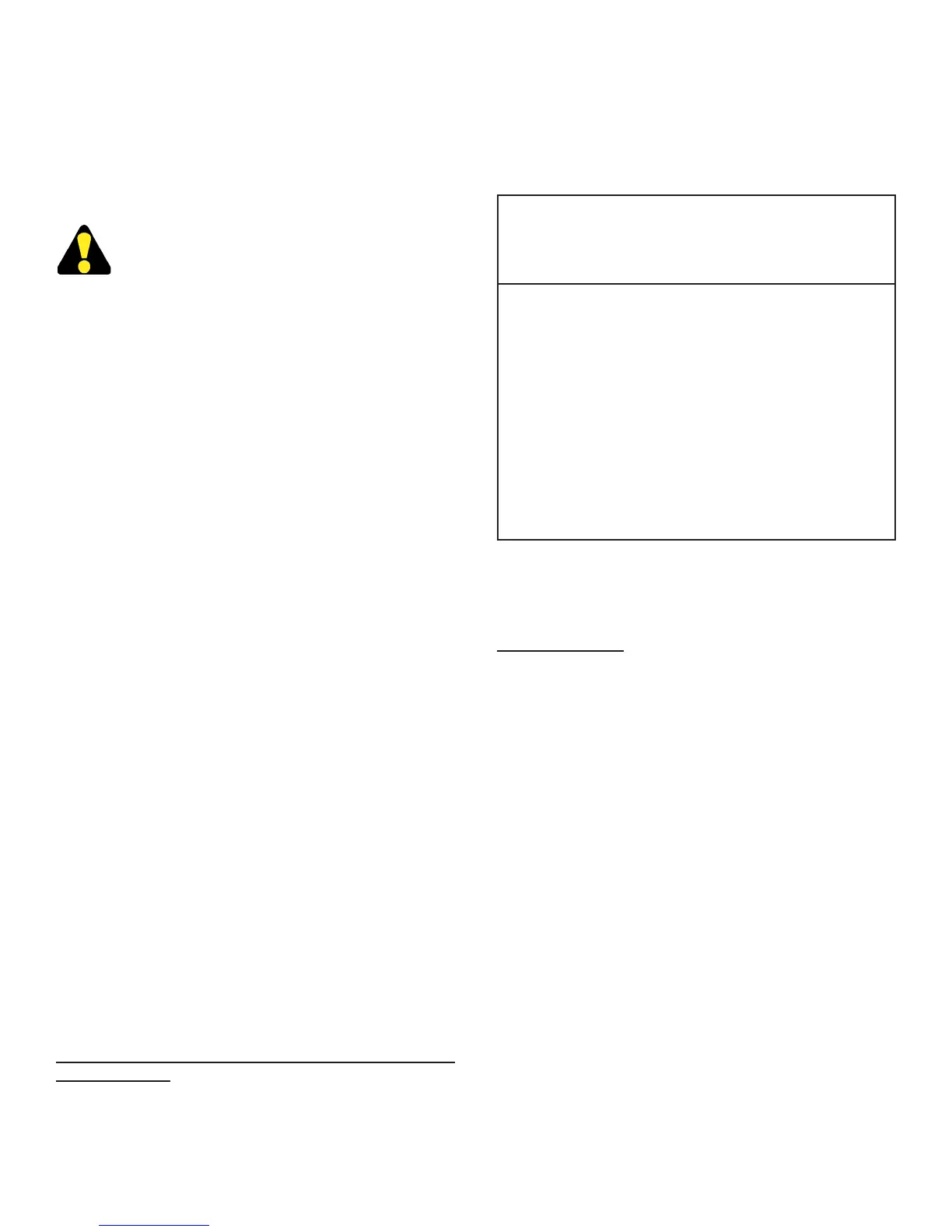

SECTION FACTOR TO APPLY

THICKNESS TO MINIMUM CUTTING

RATES GIVEN BY JOB

SELECTOR*

Up to 3/16 inch 40%

(0 to 4.8 mm)

3/16 to 3/8 inch 50%

(4.8 to 9.5 mm)

3/8 to 5/8 inch 60%

(9.5 to 15.9 mm)

5/8 to 1 inch &over 70%

(15.9 to 25 mm & over)

*Based on 5 inch (127.0 mm) solids.

Cutting Rate to Thickness Relationship.

SAW HEAD POSITIONING and APPROACH

Head Positioning

1. Use the Saw Head Control selector to initiate

vertical saw head movement in either direction

during both manual and automatic sawing modes.

Head movement during either mode can be stopped

by moving the Saw Head Control selector to

"HOLD". Moving the selector to "UP" will enable

the saw head to be raised during either operating

mode.

2. Positioning the saw head during manual

operation: (a) Move the Saw Head Control

selector to "DOWN/AUTO" when ready to begin

cutting; (b) After a cut has been nished, the saw

head actuates the head down proximity switch

(2 PRS or 2 LS) and the band drive motor stops

with the saw head completely down; (c) Raise the

saw head to position stock by moving the Saw

Head Control selector to "UP", then pushing the

Hydraulic Start button.

3. Positioning the saw head during automatic

operation: (a) Leave the Saw Head Control

selector at the "DOWN/AUTO" setting until the

required number of stock pieces has been cut,

or until no indexable stock remains on the feed

table.

2. Use the upper portion of the slide bar scale to

provide necessary clearance at the stock's top left

corner during the saw head's raising and lowering

arc. This applies for all stock widths between 3-1/2

and 16 inches (88.9 and 406.4 mm).

Both saw guide arms must clear the loaded

stock and vise jaws as the saw head raises

and lowers. This is important when cutting

maximum height rectangle stock.

FEED FORCE ADJUSTMENTS

1. Feed force is the pressure exerted by the workpiece

against the saw band's cutting edge. It is controlled

hydraulically and regulated with the Feed Force

valve. Turn the valve clockwise to "decrease"

pressure, counterclockwise to "increase" it.

2. The following are important factors to consider when

setting or adjusting the Feed Force valve:

• Turn the Feed Force valve to a low setting if the

correct feed force is not known. The operator can

then increase or decrease pressure during operation

to obtain the best cutting rate consistent with desired

blade life and stock cut nish. Always be sure to

take a good chip.

• Never start a cut with the maximum Feed Force

valve setting. Blade damage may occur.

• Certain work-hardening materials will require a

moderately heavy initial Feed Force valve setting to

assure immediate penetration of blade teeth. Light

feeds on these materials may cause the blade to slide

over the stock resulting in saw band damage.

• Generally, top performance from a sharp saw band

results from relatively low Feed Force valve

settings. It will be necessary to increase the setting

as the saw band becomes duller. This will help keep

the cutting rate constant throughout the life of the

saw band.

• Feed force adjustments are not necessary for

changing stock cross-sections. A balancing valve

enables the saw band to maintain a uniform cutting

rate.

Reducing Cutting Rate & Band Speed for Pipe, Tubing

and Structurals

1. Increasing loading per tooth occurs when sawing

thin stock sections. Although the blade teeth can

bear some overloading, a cutting rate reduction

must be made.

FEED FORCE ADJUSTMENTS (Continued....)

LEFT SAW GUIDE ARM ADJUSTMENTS

(Continued....)

Loading...

Loading...