34

MAINTENANCE

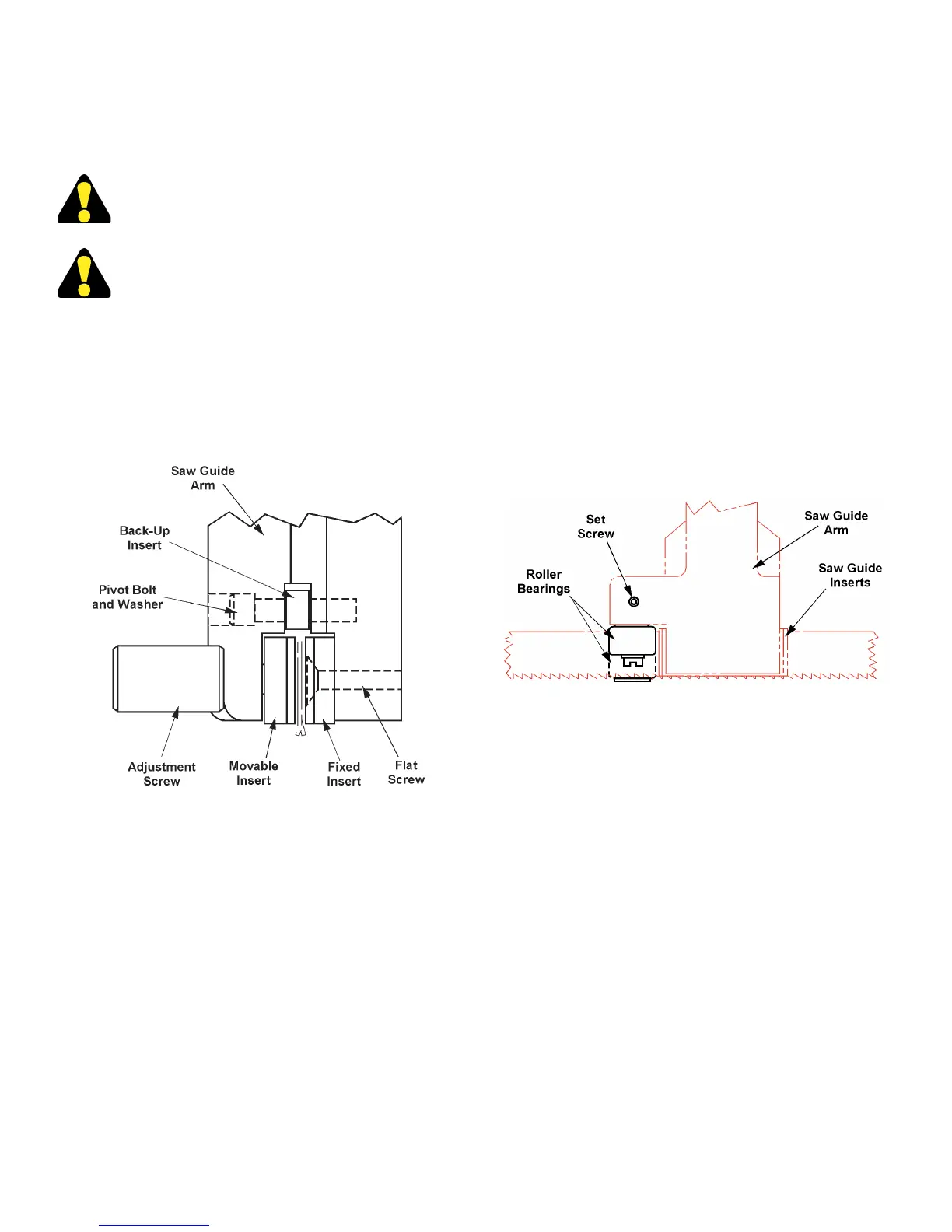

REPLACING SAW GUIDE AND BACK-UP

INSERTS

These instructions can be used to replace

the saw guide and back-up inserts on both left

and right saw guide arms.

Be sure the band drive motor is not running

when replacing saw guide and back-up

inserts.

1. Loosen the insert adjustment screw on each saw

guide arm. Then: (a) Remove the left saw band

guard (if necessary) and saw band; (b) Remove

the adjustment screw being very careful not to

drop or lose the front insert when it falls from

the assembly; (c) Loosen the at head screw and

remove the rear insert.

Typical Saw Guide Assembly (Both Arms).

2. Thoroughly clean the saw guide arm and inserts

area. Then: (a) Reverse the carbide back-up insert

(if worn); (b) Replace the rubber back-up insert if

it has deteriorated (this will help prevent coolant

leakage).

3. Install the new inserts. Then: (a) Thread the adjusting

screw inward part way; (b) Place the saw band

between the inserts; (c) Tighten the adjustment

screw; (d) Replace the left saw band guard (if

removed).

ADJUST OR REPLACE SAW BAND LEAD-IN/

EXIT ROLLERS

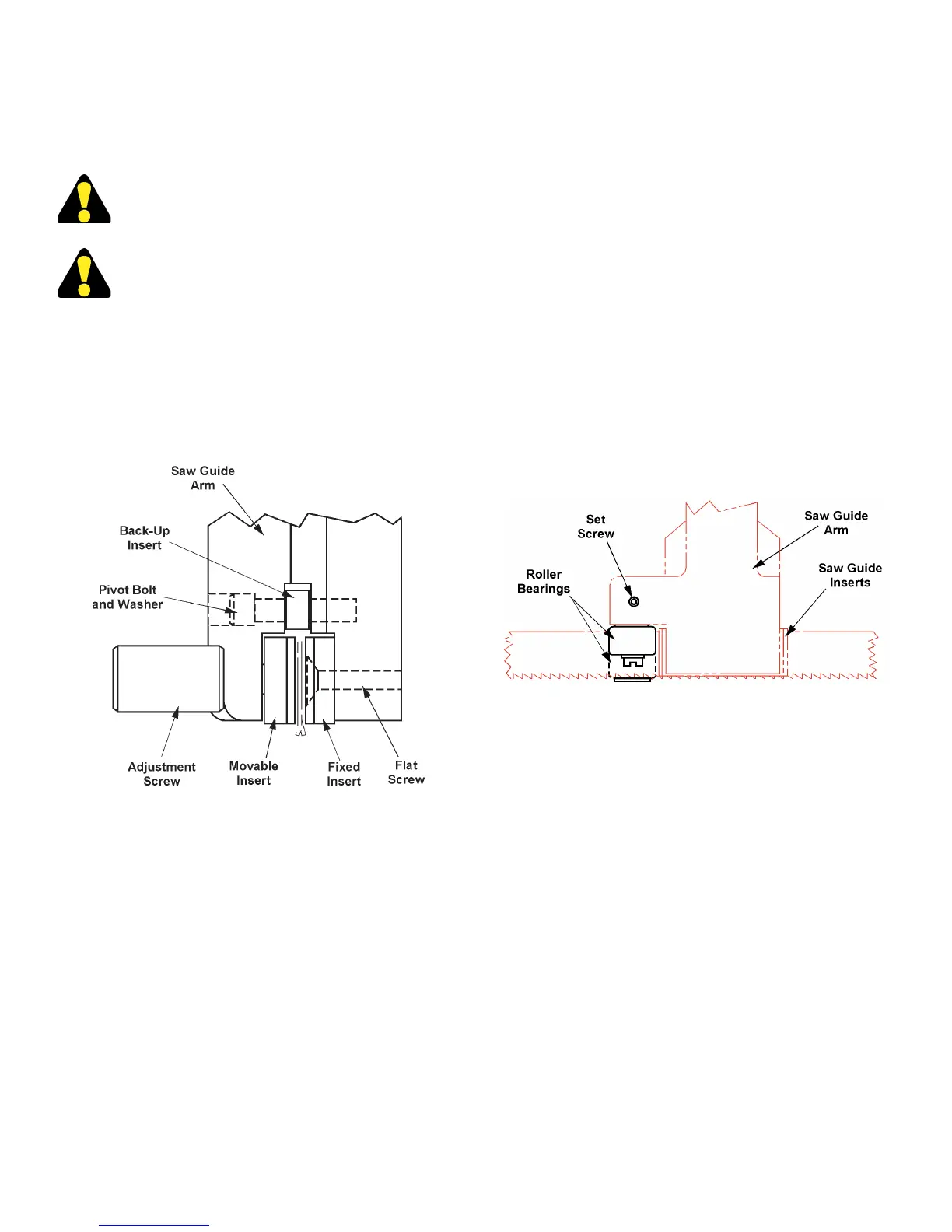

1. To adjust and position the xed spindles/rollers: (a)

Raise the saw head until the saw band is above the

front movable vise jaw; (b) Shut the machine and

disconnect switch off; (c) Move the left saw guide

arm to the closest approach to the right saw guide

arm.

2. Insert a straightedge gage and clamp the inserts in.

Position the bearing blocks so that the xed splindle

rollers bear evenly on the straightedge gage.

3. Loosen the set screw above the roller bearing and

pull out the roller bearings. Then: (a) Remove the

screw or retaining ring holding the bearing in place;

(b) Remove old bearing and replace with new one;

(c) Reinstall the screw or retaining ring; (d) Tighten

the set screw.

Lead-In/Exit Roller Bearings.

BAND DRIVE BELT REPLACEMENT

1. Turn one (1) disconnect switch to "OFF". Then:

(a) Remove the band drive assembly cover; (b)

Remove the broken drive belt.

2. Position the new drive belt over the drive pulley

sheaves. Then: (a) Adjust the motor base plate

slack take-up.

3. Turn the disconnect switch to "ON". Then: (a)

Check the operation of the new drive belt ; (b) If the

operation is satisfactory, turn the band drive motor

off; (c) Replace the assembly cover.

HYDRAULIC SYSTEM

1. Keep the reservoir lled at all times. Capacity is 10

gallons (37.5 liters). Check the reservoir oil level

daily by referring to the sight gauge.

Loading...

Loading...