26

COOLANT SYSTEM (Continued....)

Sensing Arm Operation When the Saw Head Lowers

1. The saw head lowers at the rapid approach rate

until stock is contacted by the sensing arm. A

feed approach rate is then established and cutting

begins.

2. Sensing arm contact with the stock is maintained

throughout the cut. After a cut has been nished:

(a) The head down proximity switch (2 PRS or 2

LS) is actuated; (b) The saw head raises.

MINIMUM BAR END/SPLIT FRONT VISE

1. When the indexing vise is completely forward, both

of its vise jaws extend toward the front vise jaws.

This extension, together with the nesting design of

the vises, permits automatic indexing of stock until

a small butt end remains.

2. The minimum butt end length of stock that can be

indexed is three (3) inches (76.2 mm). If the stock

is shorter, it will not be stable in the index vise.

VERTICAL GUIDE ROLLER

1. This roller mounts to the tail block at the rear of the

feed table and provides one (1) laterally adjustable

vertical roller.

2. The vertical roller is xed in relation to the xed jaw

face. When the vertical roller is not needed, it can

be removed.

HYDRAULIC SYSTEM

1. The hydraulic and band drive systems operate

independently. This allows the operator to perform

the following tasks while the band drive motor is

not running: (a) Change saw bands; (b) Raise or

lower the sawing head; (c) Clamp or unclamp the

vises; (d) Position stock manually.

2. The machine's hydraulic reservoir has a 10 gallon

(37.8 liter) capacity. Refer to the Lubrication section

of this manual for recommended oils.

COOLANT SYSTEM

Coolant Selection

1. The main cause of tooth failure during band

machining is excessive heat build-up. Using the

proper cutting uid reduces the heat generated

during operation. It also helps the machine take

full advantage of its high-speed steel saw bands.

Literature describing these and other coolant

types is available from a DoALL sales

representative.

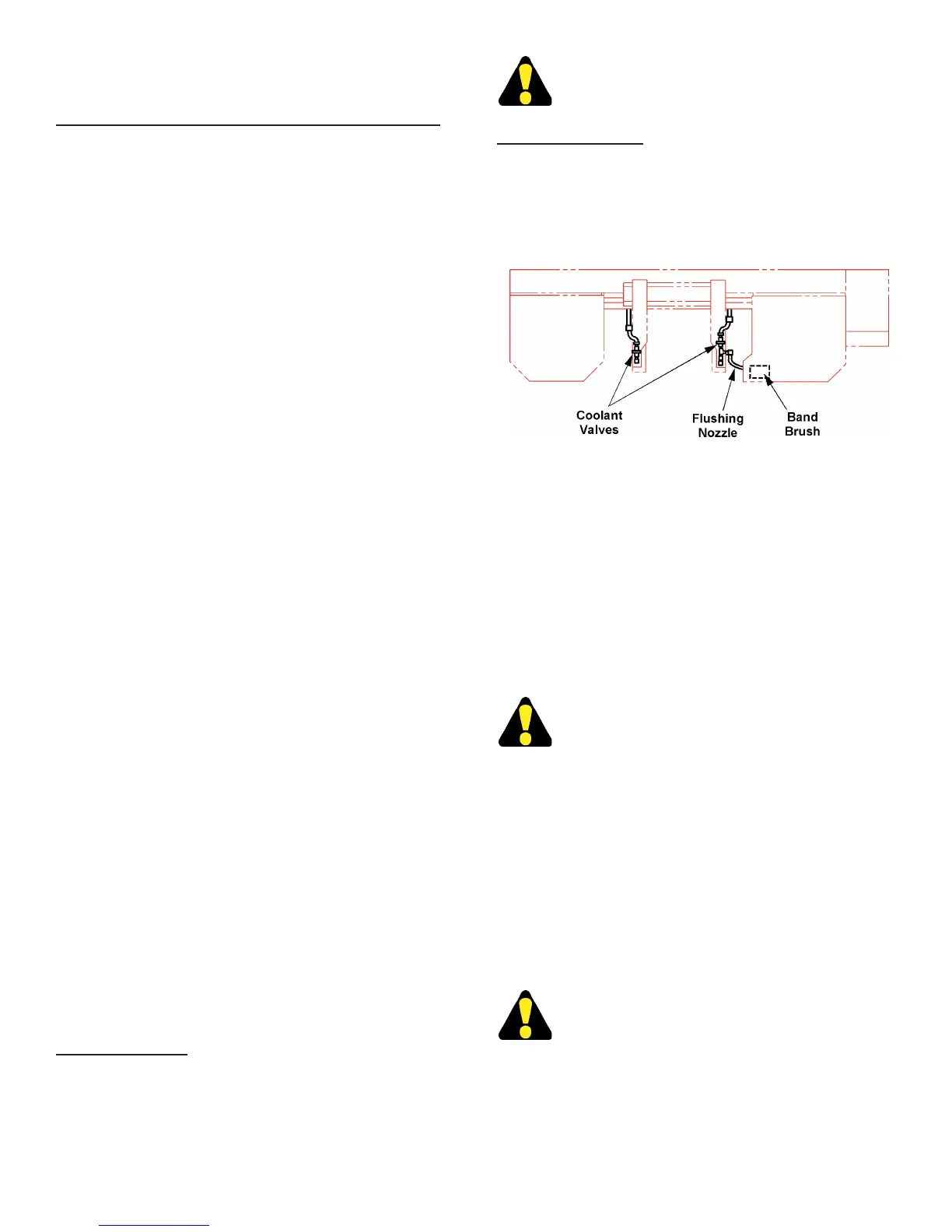

Coolant Application

1. Coolant is applied as follows during sawing:

• To the saw band and cutting area through the saw

guide inserts. Flow is regulated by a valve on each

saw guide arm.

Coolant Application Points.

• To the band brush cleaning area through a ushing

nozzle. Flow from this point is controlled by a needle

valve. If the valve orice becomes clogged, clean

it with a wire or small pin.

2. Coolant ow is started by: (a) Pushing the Hydraulic

Start button; (b) Turning the Coolant selector to

"ON" or "BAND ON"; (c) Turning the coolant valve

on each saw guide arm counterclockwise until

uid completely shrouds the saw band.

DONOTstartcuttinguntilcoolantisowing

adequately. Dry cutting will greatly reduce

blade life.

3. Check the coolant reservoir level if ow is stopped

or reduced. Reservoir capacity is 20 gallons (75.7

liters). A coolant level sight gauge is located on the

machine’s lower right side of the base.

CHIP REMOVAL

1. Metal chips should be removed from the work area as

soon as possible. They can be washed or scraped

into the right front pan opening, or scooped out with

the supplied shovel-rake.

DO NOT shovel or rake chips while the saw

band is running.

AUTOMATIC HEAD ELEVATION and SENSING

ARM (Auto Mode Only) (Continued....)

Loading...

Loading...