28

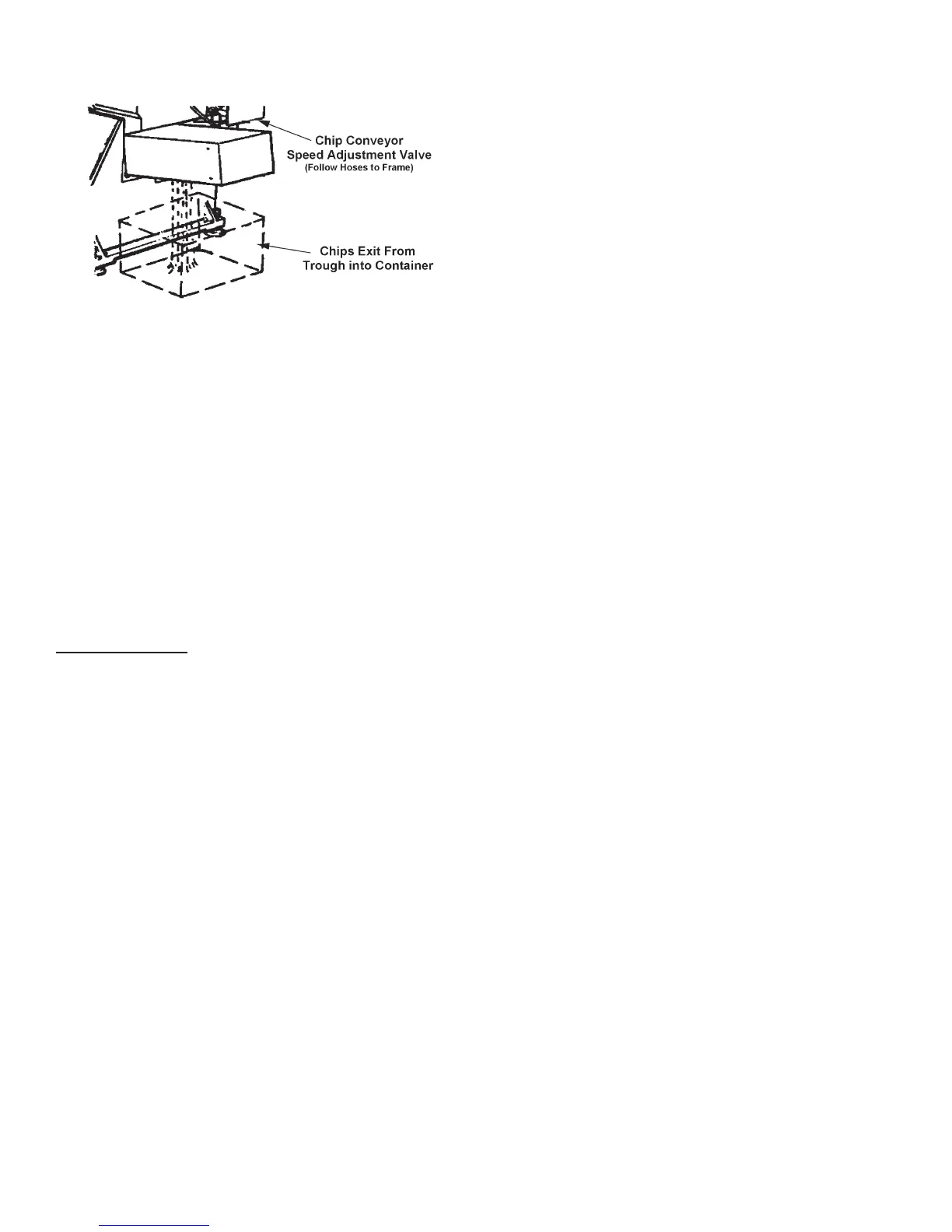

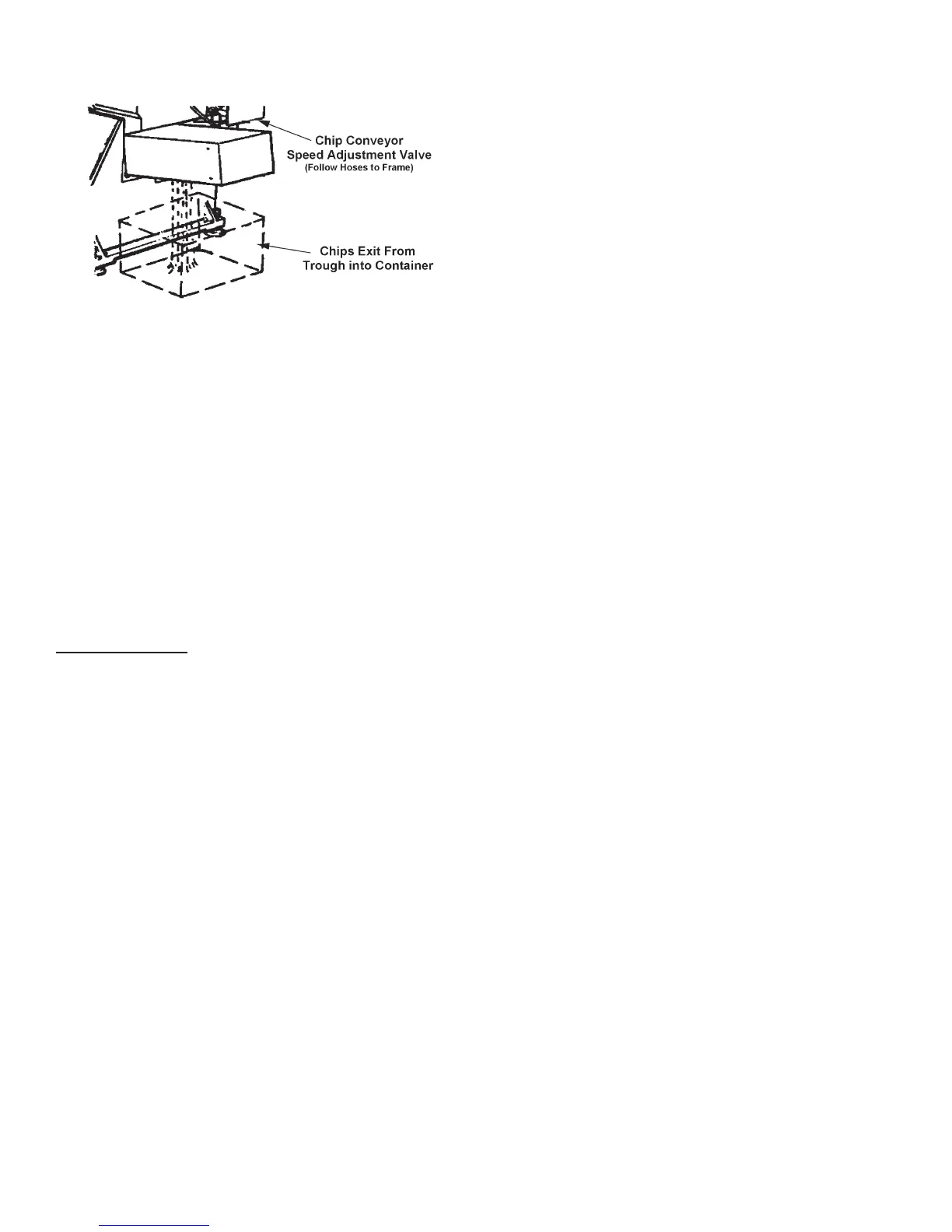

Chip Conveyor Discharges Material at Machine's Right Side.

3. A valve located on the right side near the band

drive enclosure allows the chip auger motor to be

adjusted for faster or slower operation.

IDLER WHEEL MOTION DETECTOR

1. This safety devise located on the saw head plate

behind the idler bandwheel stops the machine if the

saw band should break or stall in the workpiece.

Always determine the cause of the stoppage and

correct it before attempting to resume operation.

TYPICAL OPERATING PROCEDURES

Manual Operation

1. To start the machine: (a) Make sure the main

disconnect switches are turned "ON"; (b) Turn the

All Stop button clockwise to reset (if necessary); (c)

Push the Hydraulic Start button. This will start the

hydraulic pump motor, and illuminate the worklight

if supplied. The Display will also light up, ash all

of the LEDs and run a short test program.

2. When the machine is ready for operation, the Display

will show the a message to indicate readiness to

accept manual input, or to be set-up for automatic

operation.

3. Push the Load Prep button. The associated LED

will light up and the following actions will occur: (a)

Saw head moves to the maximum raised position;

(b) The index and xed vises open completely; (c)

The index moves completely forward ("home");

(d) The associated LED goes out to indicate the

completion of the cycle.

• Alternate Method. Raise the saw head by moving

the Saw Head Control selector to "UP". Then: (a)

Move the Saw Head Control selector to the "HOLD"

setting when the saw head reaches the desired

height; (b) Before starting a new job, it may be more

convenient to raise the saw head to its maximum

to be sure it will clear the material to be loaded; (c)

Push the Index Open (F9) and Fixed Open (F11)

buttons.

• Operating Notes: (a) The saw head must be raised

completely to allow complete opening of the vise

jaws, or to accomodate a stockpiece wider than

the piece previously clamped; (b) If the saw head

is not completely raised, the vises will open just

slightly wider than for the previous stockpiece.

4. Load the stock to be cut onto the feed conveyor

rollers near the xed vise jaws and position for a

crop cut.

5. To move the stock into position for clamping by

the xed vise jaws: (a) Move the index vise to the

rear or almost to the rear of its travel; (b) Clamp

the index vise jaws; (c) Push the Index Forward

or Index Reverse buttons to position the stock for

a crop cut (1/4" (6.3 mm) or more of material must

be extending beyond the path of the saw band).

• Operating Notes: (a) The index will move slowly

for the rst few seconds after the Index Forward

or Index Reverse button has been pushed, then

move at a rapid rate; (b) For slow positioning, use

the Creep Speed button for slow positioning as

needed.

6. Push the Fixed Clamp button to clamp the xed

vise jaws around the stock. Then: (a) Move the

Saw Head Control selector to "DOWN/AUTO" and

position the saw band just above the stock; (b) Push

F2 to respond to the message that the saw band is

not on; (c) Move the Saw Head Control selector

to the "HOLD" setting.

7. Push the Band Speed (F5) button. Then adjust

band speed by entering the band speed directly.

You can also use the "UP" and "DOWN" keys to

adjust band speed.

8. Select the coolant ow desired for your application.

Make sure to cover both sides of the saw band. To

begin the cut: (a) Move the Saw Head Control

selector to "DOWN/AUTO"; (b) Push the Band/

Cycle Start button. The band drive will come up

to speed and the saw head will feed down to begin

the cut.

9. The operator may adjust band speed, coolant ow,

rapid approach rate, and/or feed force at any time

during the sawing process.

CHIP REMOVAL (Continued....)

Loading...

Loading...