15

5. Press the Next Screen key to scroll to the next

screen.

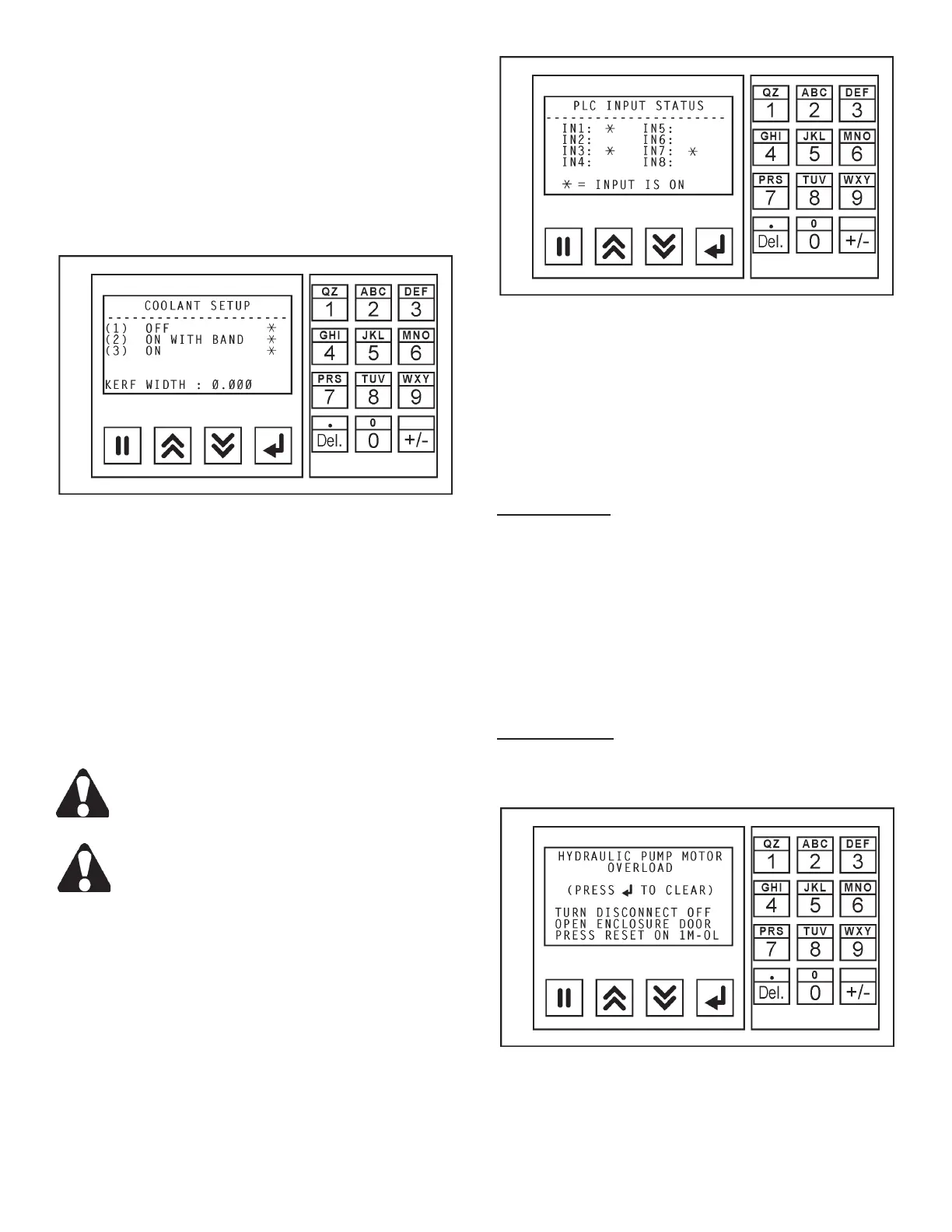

6. This screen shows the controls for COOLANT

SETUP and KERF WIDTH data entry.

• A blinling star symbol after a selection indicates that

this control is in operation.

Coolant Setup Screen.

• Press the "1" key on the numeric keypad turns

OFF the coolant ow; press the "2" key turns ON

the coolant ow with the saw band running; press

the "3" key to turns the coolant ow ON with the

saw band not running.

• To enter the kerf width of the saw band, press the

Data Entry function key. Then: (a) With the kerf

width eld highlighted, enter the kerf width of the saw

band using the numeric keypad; (b) Press the Ac-

cept function key to enter the data into memory.

Remember, changing between the INCH and

mm settings will require that any data entered

for kerf width will need to be changed also.

If you make an error in entering data, just press

the Data Enter key again, change your entry

and then press the Accept key.

7. Press the NextScreen key will bring the operator

to the rst screen.

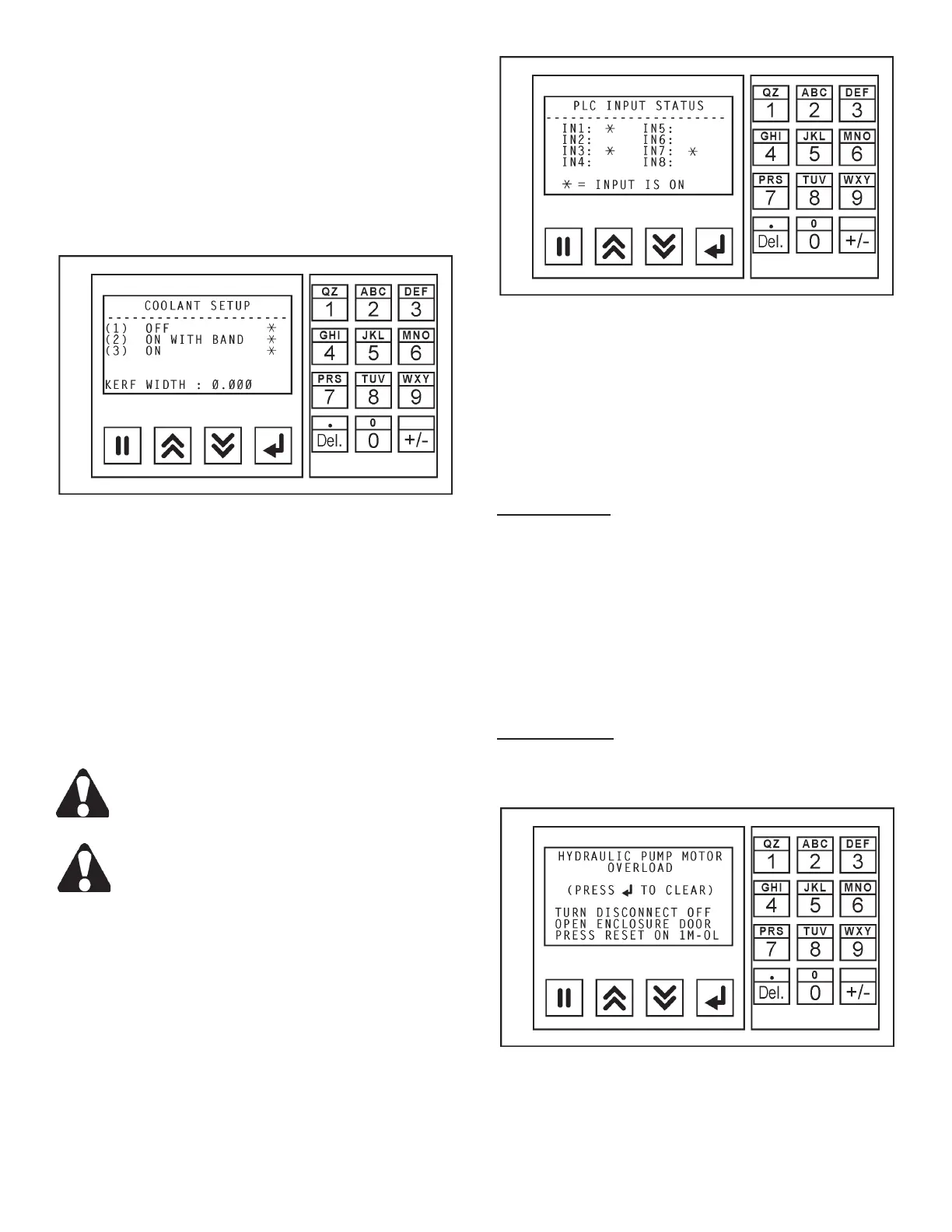

8. Press the "9" key to see the I/O STATUS group of

sub-menu screens.

I/O Status Screen.

• A series of screens will appear which show different

input and output modules and their status. These

screens are for diagnostics and service only and

needs NO interaction from the operator.

• A blinling star symbol after a notation indicates that

this module is in operation.

Operator Notes

1. The minimum length that can be entered is 0.50

inch (12.7 mm).

2. To skip a job or jobs in a list, set the quanities to 0

(zero) on those jobs to skip.

3. The operator may want to check and review the se-

lections and data entered by scrolling "up" or "down"

through the sub-menus before proceeding.

Error Messages

1. When an error condition occurs, a message will

appear on the Display and an alarm will sound.

Typical Error Message.

2. The operator must make the proper corrections

before machine operation can continue.

MACHINE CONTROLS (Continued....)

Loading...

Loading...