- 11 -

INLET WATER SYSTEM

The inlet hose is connected to the inlet valve (normally closed). When the

outlet pressure sensor detects a low pressure (lower than the preset start pres-

sure), does the printed circuit board (PCB) energize the inlet valve, and the

valve opens (and the motor starts). The inlet valve includes a screen lter, for a rst

coarse particle ltration.

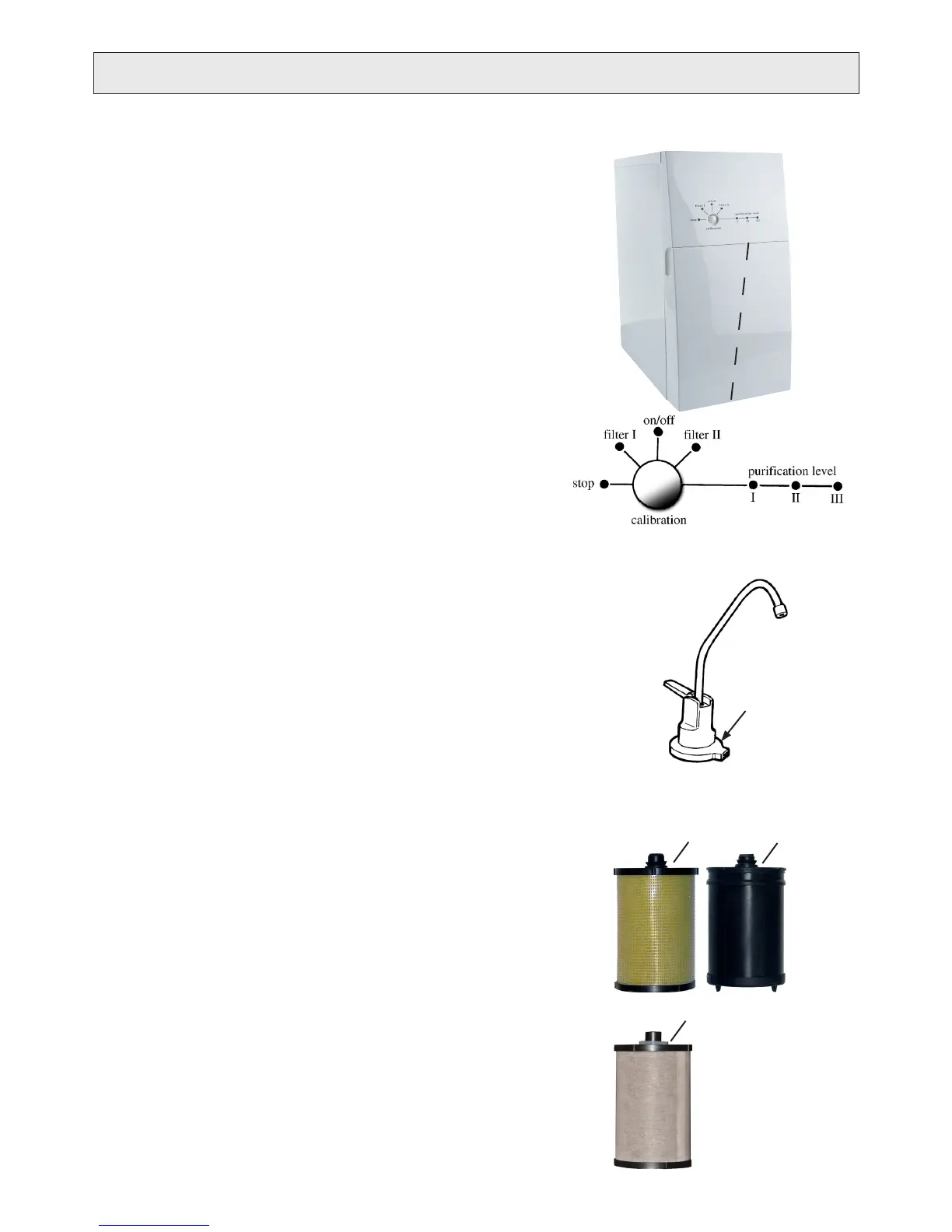

The inlet water ows to the integrated prelters that consist of two lter

cartridges, congured in

- serial ow (in most RO400-models) or

- parallell ow (in most RO600-models)

The purpose of the preltration is to protect the membrane , from mechanical and

chemical wearing. Better preltration gives longer service life of the membrane and

the product overall.

In serial ow does the preltration consist of one particle (sediment) lter and

one granulated activated carbon (GAC) lter . The particle lter removes par-

ticles larger than approx 10 µm. The carbon lter reduces Chlorine (Cl

2

), which is

important as the surface the membrane otherwise is damaged by Chlorine over time.

In parallell ow does the preltration consist of two identical carbon block lters

. The carbon block combines particle removal (larger than approx 5 µm) and

Chlorine reduction in one cartridge. The advantage of parallell ow is the lower

pressure drop, which becomes more important at high water ow (RO600 compared

with RO400). The ner particle ltration gives an improvement not only on the

membrane service life, but also the integrated high pressure pump .

3

1

H

F

In the following, the letters/numbers within brackets refer to gure.

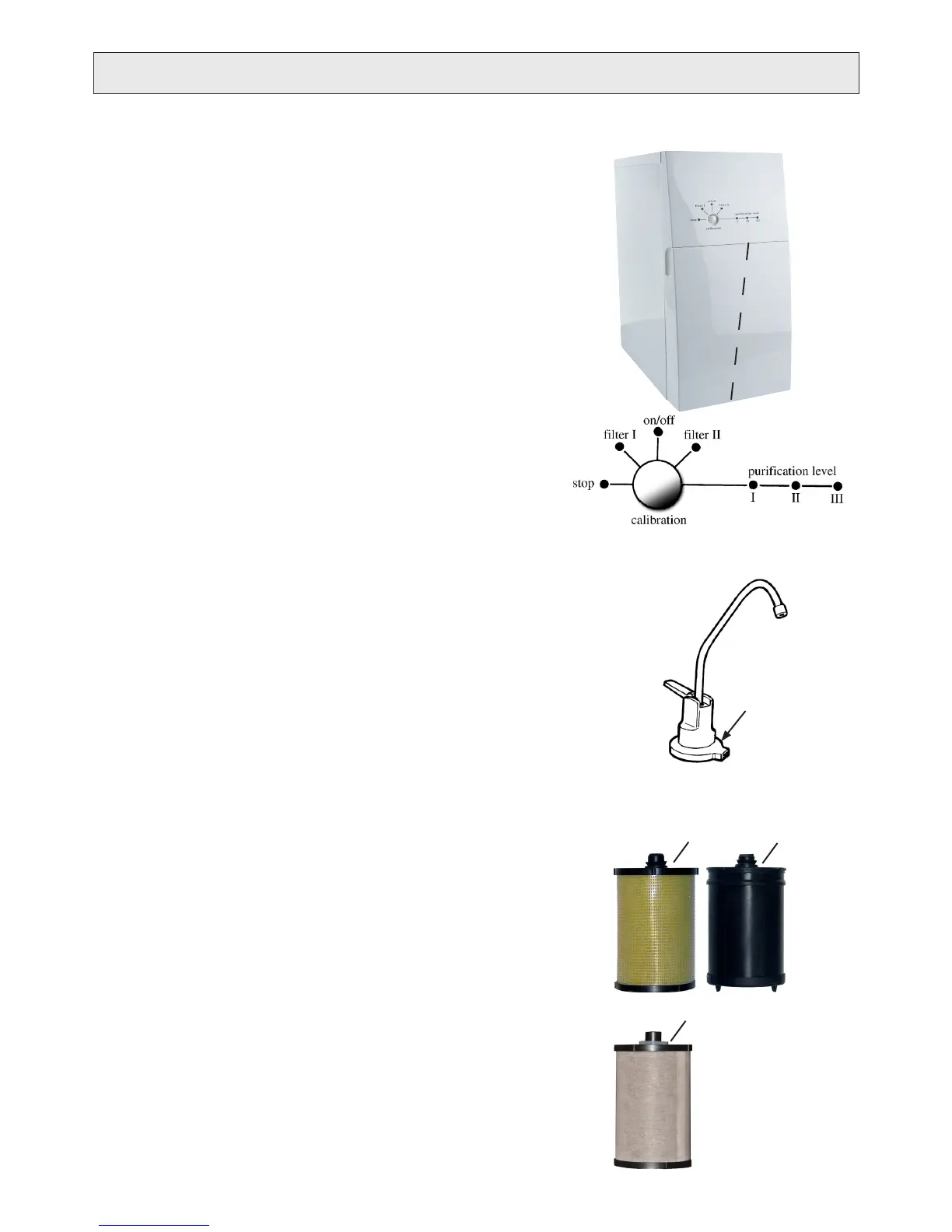

INDICATOR LIGHTS AND BUTTON

On the control panel of the water purier there are seven indicator lights (diods,

LEDs) and one push button, see g. F.

stop The product has stopped working. ‘stop’ alone or

with another diod gives an error code indicating the fault.

Change prelter/s/.

Too low pressure at the inlet, caused by blocked lters/s/,

low water supply pressure e.g.

on/off Indicates that the product is switched on (power on).

Change prelter/s/.

Filter/s/ consumed due to time in use.

Low purication level.

Good purication level.

High purication level.

calibration button Push button to

- calibrate levels for purication level,

- reset timer function of ‘lter II’,

- enter varios modes and control

functions useful during service.

For more information about indications, see “TROUBLESHOOTING”.

Indicator lights

An accessorie, see g. G, aimed for products installed under kitchen sink when

control panel is not always visable. It is intended to be mounted below the drinking

water faucet and connected to the indicator contact on the product backside.

- Green light indicate ‘purication level II / III’.

- Red light indicate ‘purication level I’

PRODUCT DESCRIPTION

2

1. Particle lter

2. Granulated Activated

Carbon (GAC) lter

3. Carbon block lter

G

Indicator lights

Loading...

Loading...