- 13 -

PRODUCT DESCRIPTION

PURIFIED WATER SYSTEM

After the puried water leave the membrane pressure vessel, it pass through the

pressure regulating valve . This is a safety feature, to avoid high pressure to

the distribution net in case of failure, and to protect the the product from water ham-

mer when a valve or faucet is closed on the pure water hose.

Before the puried water outlet the pure water passes a conductivity sensor

, described under “WATER QUALITY MONITORING”, a check valve

(integrated in the puried water outlet) and pressure accumulator valve . The

check valve prevents back ow to the product. The pressure accumulator valve

buffers a small quantity of water to compensate for small internal or external leak-

ages and has also a reducing effect of water hammer.

Attached to the pressure accumulator valve is the outlet pressure sensor . The

outlet pressure sensor measures the pressure in the puried water outlet, and gives a

signal to the electronics to start and stop the product.

The pressure drops if a valve or faucet opens or if a connected tank needs lling;

and the pressure increase when a valve or faucet closes or if a connected tank is

lled up.

Low pressure starts the product, described under “INLET WATER SYSTEM”.

High pressure stops the product, but before closing the inlet valve and the motor, is

a ushing performed, described under “FLUSH SYSTEM”.

See Table 1 for values.

FLUSH SYSTEM

The purpose of ushing is to ll up the system, exchange old water inside the prod-

uct or ush out an increased concentration of contaminants after a production cycle.

With the motor running and inlet valve open, is the ush valve energized to open

completely. Reject ow goes from approx 2 / 2.5 litres/minute to more than 6 l/

minute.

The ushing takes place in four different situations:

When the product is connected to electrical supply, does the product ush 30 a)

seconds. This is done to ll up the system when a product is new or to manu-

ally efciently replace the water inside the unit.

This ush cannot be interrupted by production of puried water.

The product ush approx. every 12 hours (starting when the product is con-b)

nected to electrical supply), for 30 seconds, in order to replace the water

inside. This is done to avoid biological growth. Therefore is it important that

the product is connected to electrical and water supplies.

This ush is interrupted if puried water is required.

After every production cycle does the product ush the system, to ush out c)

an increased concentration of contaminants. The ushing time is relative to

the time the product was in operation. As indication should ush be about 20

seconds after 2 minutes operation. Maximum ush time is 90 seconds.

This ush is interrupted if puried water is required.

Only applicable to commercial (C-) models: d)

When operation cycles are long, does the product make an automatic ush

for two minutes every 15 minutes operation, i.e. 15 - 2 - 15 - 2 ... The reason

is the same as for point c) above.

This ush cannot be interrupted by production of puried water.

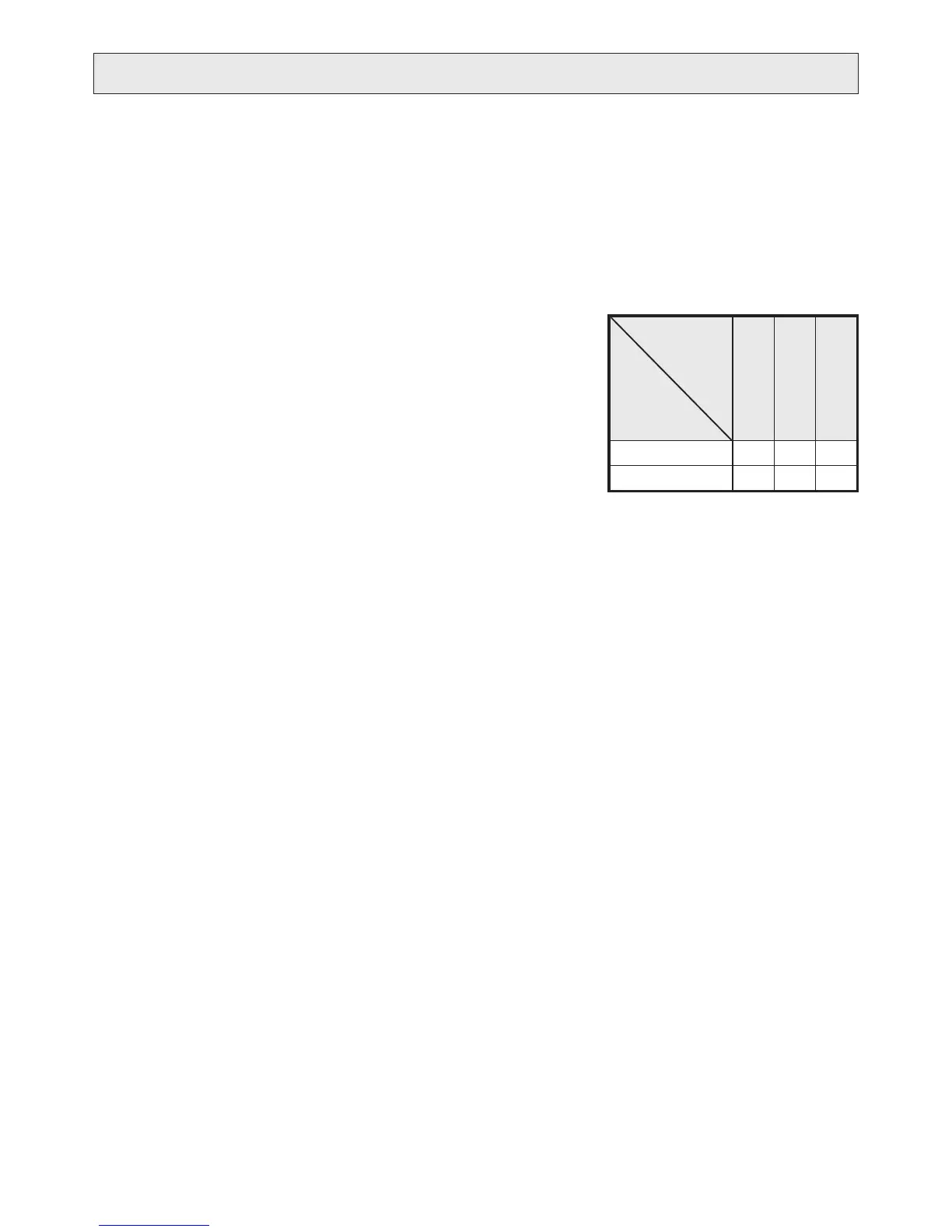

MODEL

PRESSURE

(bar)

RO400A

RO400B-models

C-models

Start level 0.5 0.5 3

Stop level 4.5 2 4.5

Table 1.

Loading...

Loading...