- 39 -

17

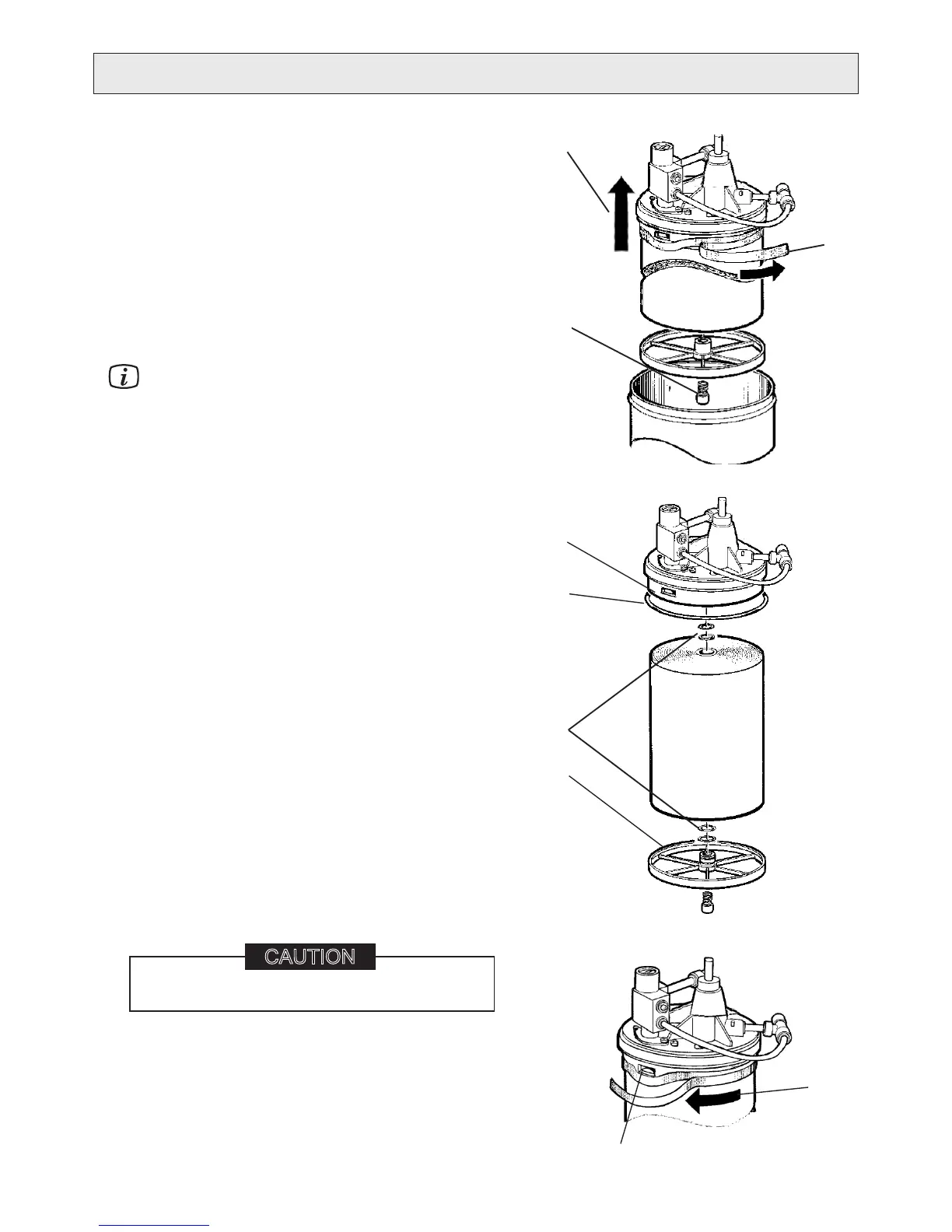

With the tee-hande, pull the pump/membrane assembly 14.

up (). Let most of the water drain off from the mem-

brane into the vessel before taking the assembly out.

Remove the spring and the end bushing (15. ) from the

lower membrane gable, and put aside.

Clean the inside of the membrane pressure vessel.16.

Lubricate with silicon grease the sealing surface for the 17.

big o-ring inside the vessel (below the seat for the lock-

ing rings, and 20 mm down).

Remove the tape that keeps the pump and membrane 18.

together ().

The procedures differs if the membrane and/or pump 19.

will be replaced.

Replacing the membrane service kit:

Replacing the pump service kit:

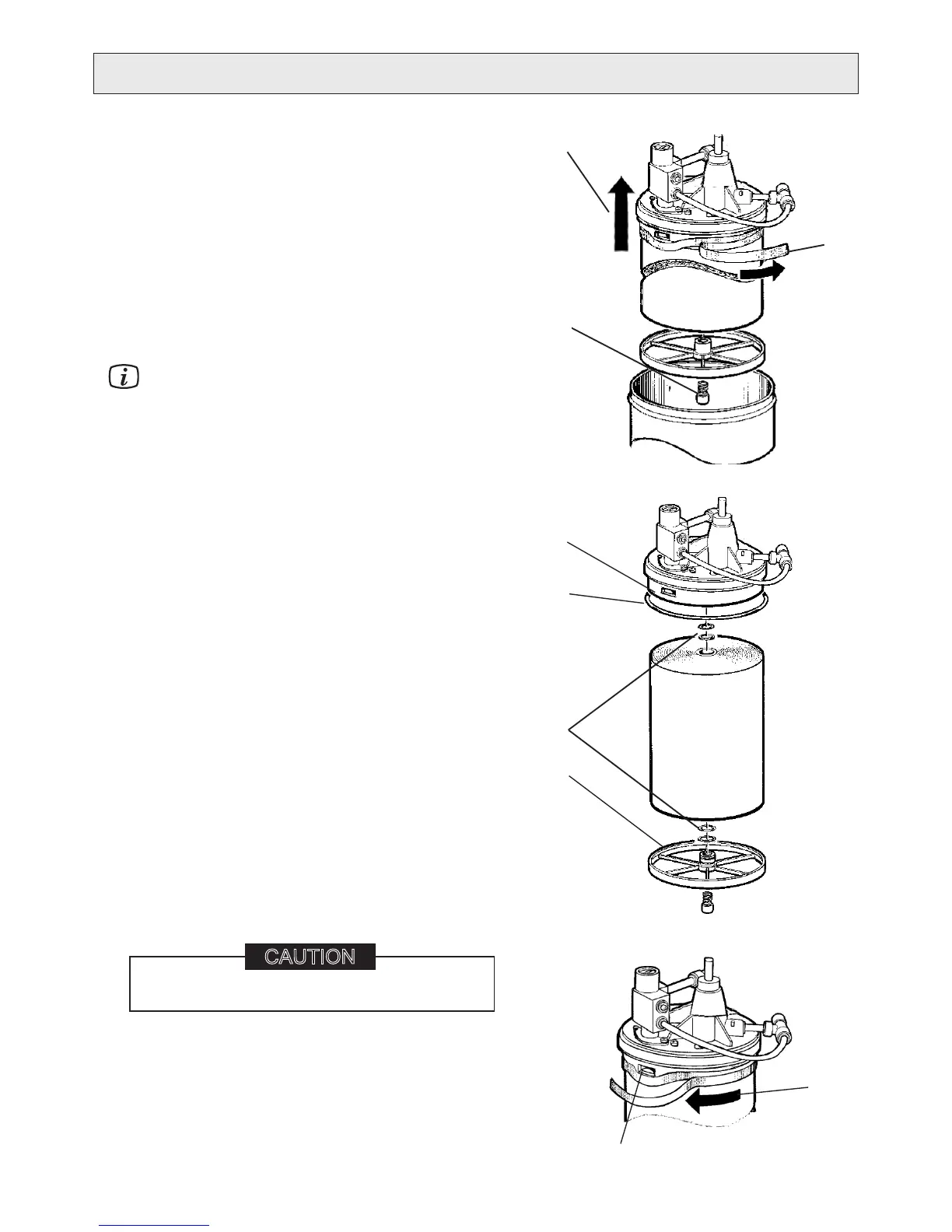

Put the pump gable/housing onto the membrane ele-20.

ment.

Clean the upper plastic gable and the membrane ele-21.

ment from tape remains.

Let the pump/membrane assembly stand with the mem-22.

brane element downwards.

Tape the membrane element to the upper plastic gable.

Start from the right side of the loop ow hole and tape

clockwise 2.5 revolutions (). End on the left side of

the loop ow hole.

Lubricate the new, big, o-ring (23. ) and put it on the

pump gable.

Install the spring and end bushing on the lower plastic 24.

gable ().

Lower the whole pump/membrane assembly into the 25.

pressure vessel.

SERVICE

11

Continues from previous page

Unpack the membrane element.a)

Lubricate with silicon grease four o-rings (b) ). Attach

two o-rings to the new lower membrane gable ().

Mount the gable to either side of the membrane ele-

ment.

Replace with two new o-rings on the upper mem-c)

brane gable ().

Unpack the pump gable/housing.a)

Lubricate with silicon grease two o-rings (b) ). Attach

the o-rings to the new upper membrane gable (),

attached to the pump.

Move the tee-handle (c) ) and the three locking pieces

(4) from the old brass gable to the new.

Loading...

Loading...