28

Maintenance

Carrying Out the Function Test

with Gas (Bump Test)

Manual implementation without the

documentation of result in the device

memory

● Prepare a test gas cylinder, the volume

flow must be 0.5 L/min and the gas

concentration must be higher than the

alarm setpoint concentration to be tested.

Example test gas cylinder 68 11 130 =

mixed gas with 50 ppm CO, 15 ppm H

2

S,

2.5 vol. % CH

4

, 18 vol. % O

2

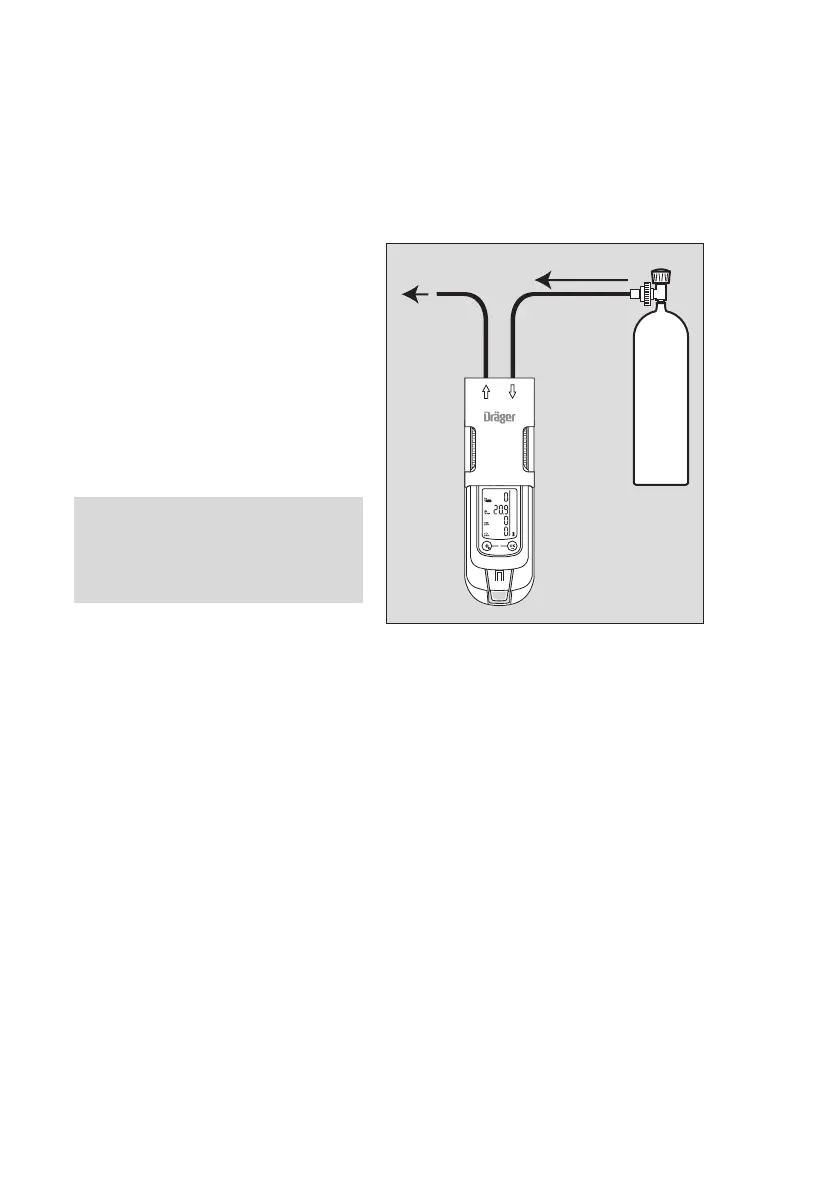

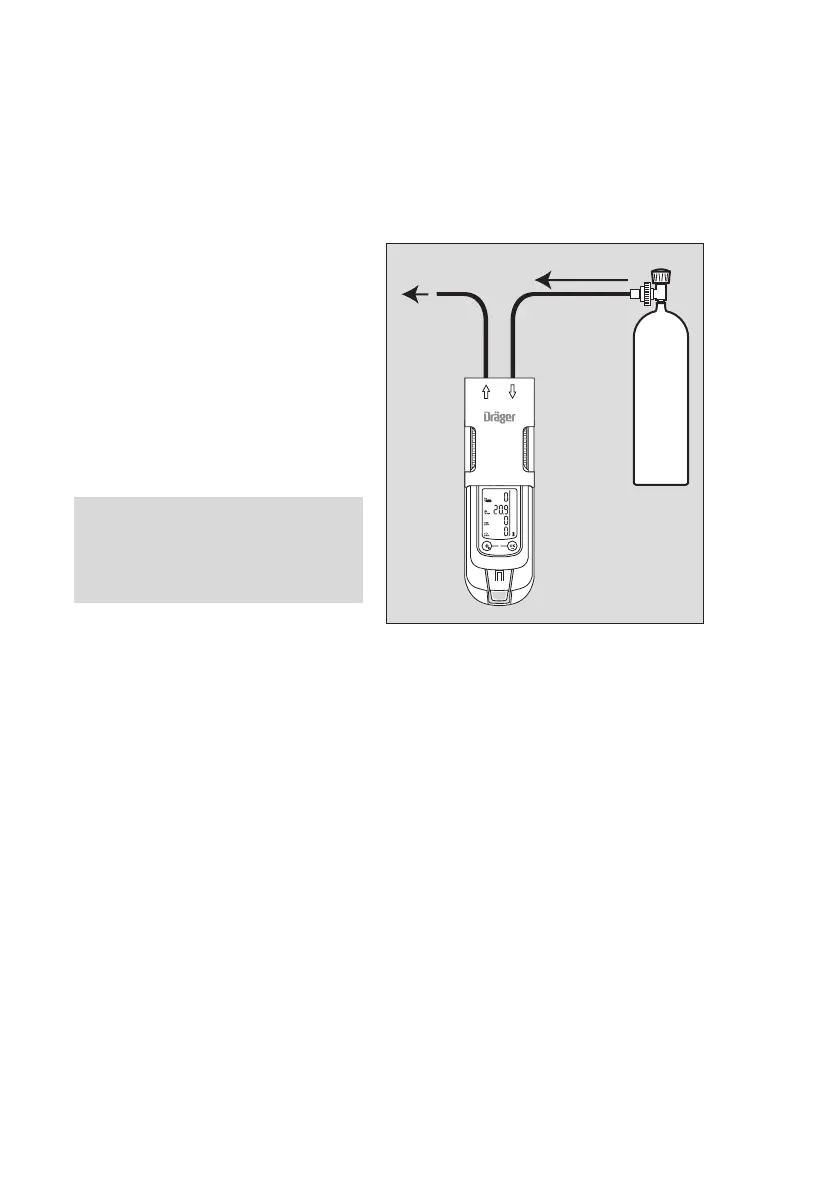

● Connect the test gas cylinder with the

calibration cradle (83 18 752).

● Vent the test gas into a fume cupboard or

into the open air (with a hose connected

to the second connector of the calibration

cradle).

● Switch on the device and insert it into the

calibration cradle – press downwards

until it engages.

● Open the test gas cylinder valve to let test

gas flow over the sensors.

● Wait until the device displays the test gas

concentration with a tolerance of ±20 %.

If the alarm setpoints are exceeded, the

device displays the gas concentration in

alternation with » A1 « or » A2 «

depending on the test gas concentration.

● Close the test gas cylinder valve and

remove the device from the calibration

cradle.

— If the concentration has now fallen under

the A1 alarm setpoint:

● Acknowledge the alarm.

● If the device does not display the test gas

concentration within a tolerance of

±20 %:

● Calibrating the device, refer to page 34.

ATTENTION:

Test gas must not be inhaled. Risk to

health!

Observe the hazard warnings of the

relevant Safety Data Sheets.

00523854_01_en.eps

0.5 L/min

0

Loading...

Loading...