11

Owner's Manual for DUKE TSC Proofer Oven

with Touch Screen Controls

This equipment is intended to be connected to a

potable water supply system under pressure and is

to be installed with adequate backflow protection

to comply with all applicable federal, state, and

local codes.

Water supply pressure for proper operation shall be:

Minimum 40 PSIG(275 KPa)

Maximum 65 PSIG(448 KPa)

measured at water line inlet to the equipment.

If so equipped, regular maintenance is required to

replace the water filter cartridge at least once per

year, and to clean the inlet water screen at least

once per year. Consult state/local codes for any

additional requirements.

INSTALLATION OF WATER FILTER

Install new filter by removing sanitary cap from top

of cartridge, insure two black O-rings are in place,

then lift up into filter head and rotate cartridge

1/4 turn counter clockwise until it comes to a complete

stop. Flush 2 gallons (5.6 Liters) of water through the

new filter before using proofer to purge air from filter.

Remove hose from bottom of proofer by loosening

the compression nut at the disconnect fitting

and pull hose out. Place hose over container and

turn on water. It will take a minute for the filter

to fill before water flows out of hose into container.

once filter is flushed with 2 gallons (5.6 Liters) of water,

turn off water supply again, insert hose into water line

disconnect, tighten compression nut and turn

water supply on again. Check for leaks at

connection fittings.

Patent(s) Pending

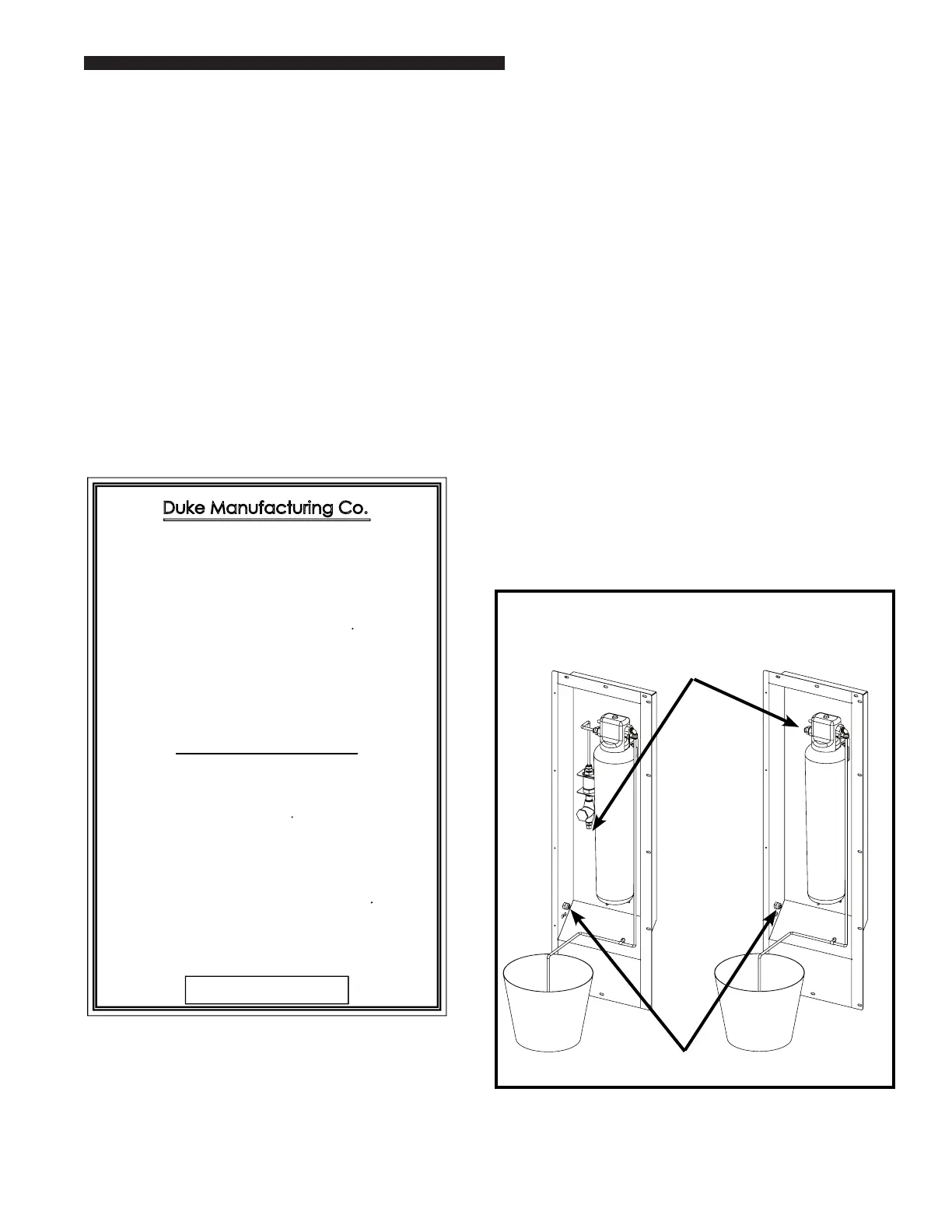

INSTALLATION OF WATER FILTER

1. Install new lter by removing sanitary cap from

top of cartridge, insure two black O rings are

in place, then lift up into lter head and rotate

cartridge 1/4 turn counter clockwise until it

comes to a complete stop.

• Flush 2 gallons (5.6 Liters), of water

through the new lter before using proofer

to purge air from lter. Remove hose

from bottom of proofer by loosening the

compression nut at the disconnect tting and

pull hose out. Place hose over container and

turn on water. It will take a minute for the

lter to ll before water ows out of hose

into container.

• Once lter is ushed with 2 (5.6 Liters),

gallons of water, turn o water supply

again, insert hose into water line disconnect,

tighten compression nut and turn water

supply on again. Check for leaks at

connection ttings.

Figure 3: Water Filter (Flushing 2 gallons

(5.6 Liters), of water)

The two main components of the Duke backow

preventer system are:

• Dual Check Valve type backow preventer

that conforms to ANSI/ASSE standard #1024

and is CSA standard B64.6 certied.

• Inlet water strainer equipped with 100-mesh

screen and installed up stream of the backow

preventer. The screen is conveniently located

on the rear panel of the proofer, below the

backow preventer, for easy access during

cleaning/replacement.

Water Line

Disconnect Fitting

Factory Installed

or Kit Backow

Preventer Inlet

Water Connection

Inlet Water

Connection

Point

Water Connection

if Backow

Preventer is Not

Required

acting check valves, internally force-loaded

to a normally closed position and designed/

constructed to operate under intermittent or

continuous pressure conditions.

Loading...

Loading...