SECTION 2 - MAINTENANCE & ADJUSTMENTS

BACKGAUGE SQUARENESS

The backgauge must be parallel to the cutting line.

If there is any misalignment adjust the backgauge

accordingly. Test cutting table squareness before

testing the backgauge.

TESTING FOR BACKGAUGE SQUARNESS

1. Cut several sheets of paper at the same time.

Align them against the right side of the cutting

area and evenly against the backgauge.

2. Remove and discard the pieces closest to the

operator.

3. Turn the remaining sheets over and push them

against the left side of the cutting area and

against the backgauge.

4. Observe any excess trimmings from the cut. If

there are any pieces left over, perform the

backgauge alignment.

BACKGAUGE ALIGNMENT

1. Determine what correction is necessary (see

“Testing for Backgauge Squareness”).

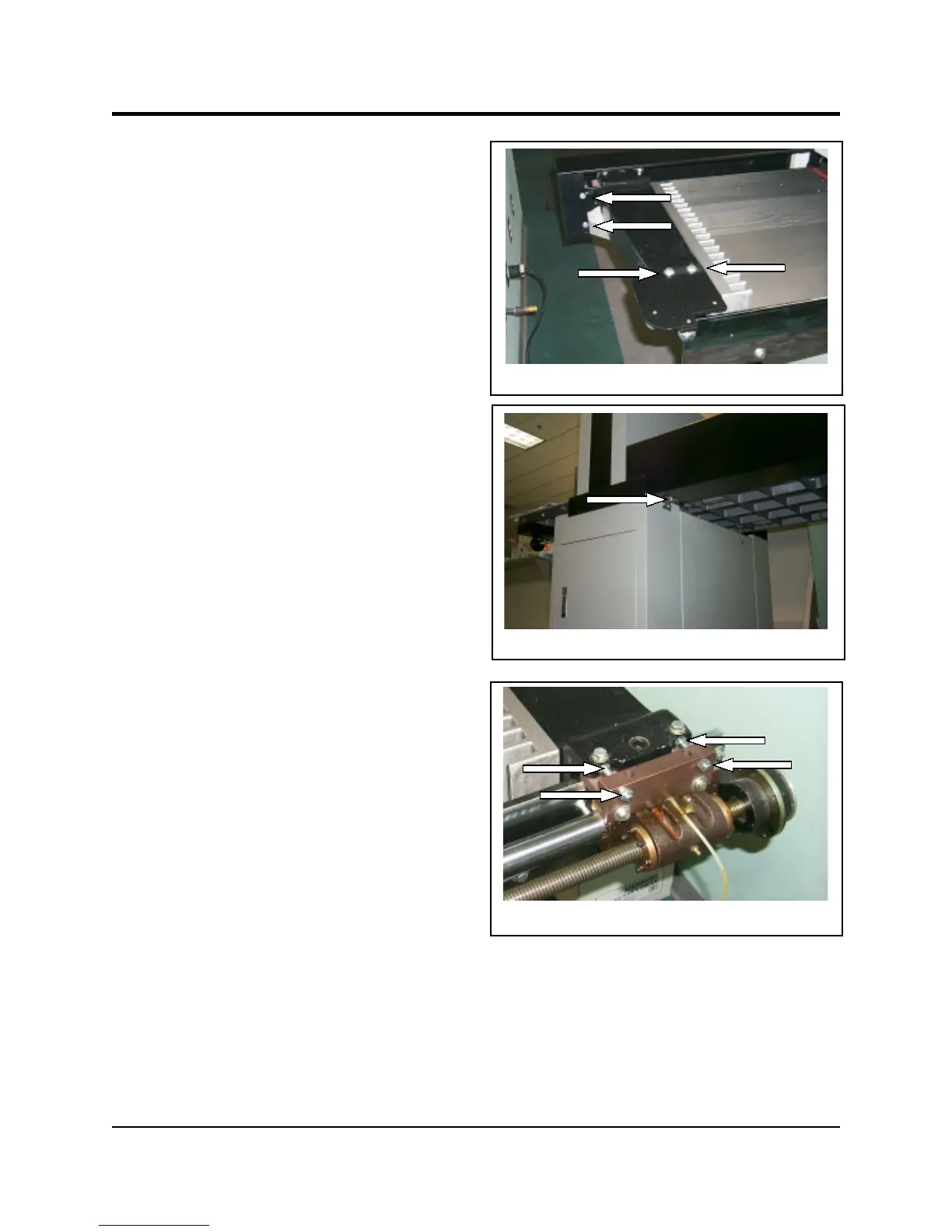

2. Remove the two screws A, see Figure 3.

3. Remove screw A and remove the backgauge

drive cover, see Figure 4.

3. Loosen, but do not remove, the two bolts B on

the left side of the backgauge, see Figure 3.

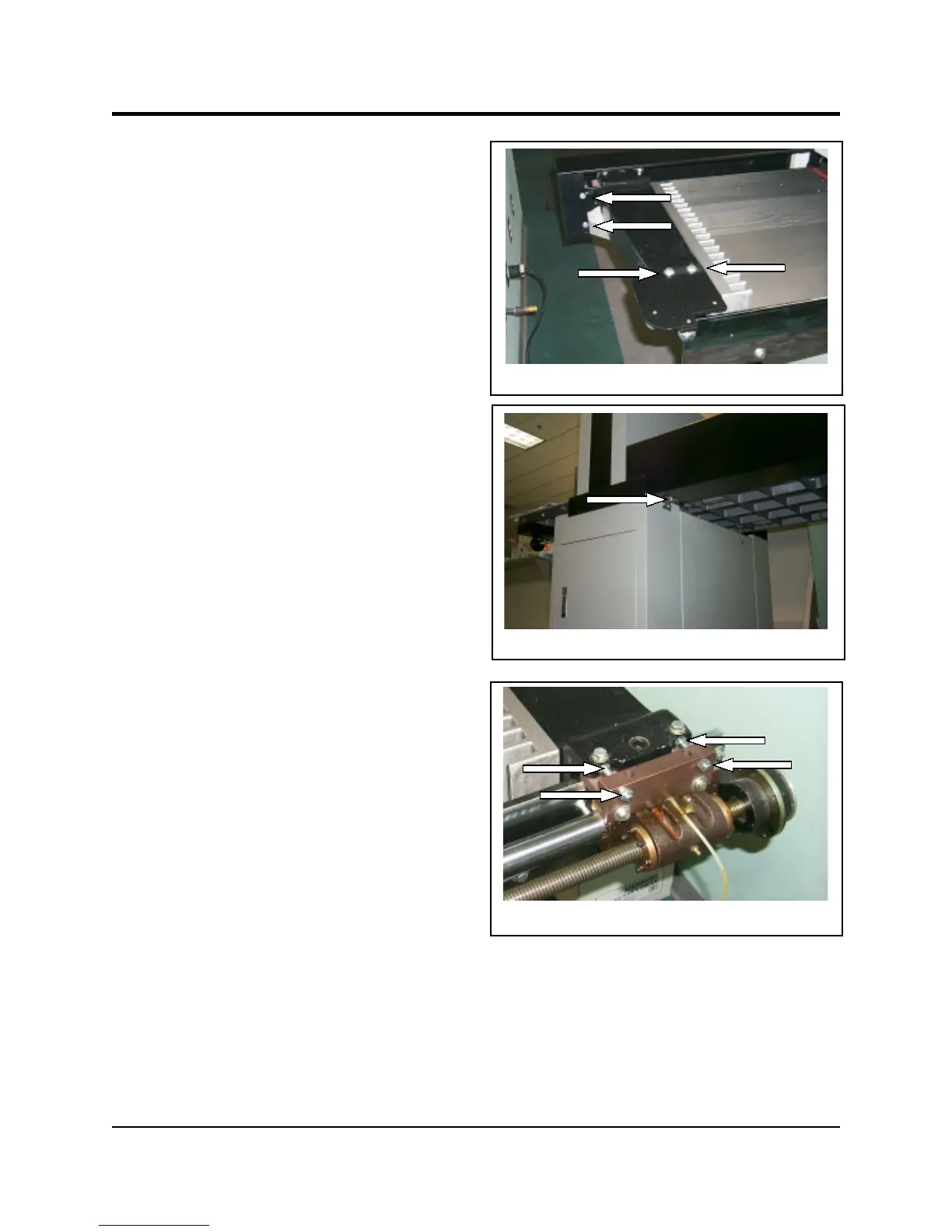

4. Loosen, but do not remove, the two nuts B on

the right side of the backgauge, see Figure 5.

5. Adjust the two bolts as necessary to “square

up’ the backgauge to the cutting line.

6. Test for squareness. When satisfactory, lock

the bolts from steps 3 and 4.

7. Reinstall the backgauge drive cover.

CUTTING ACCURACY

See the Electrical Section for details on setting the

“Rear Calibration Point.”

Figure 3 - Backgauge Drive Cover Rear Bolts

A

B

A

B

Figure 4 - Backgauge Drive Cover Rear Bolts

A

A

A

B

B

Figure 5 - Backgauge Adjusting Bolts

660P Cutter

2 - 5

https://www.supplychimp.com

Loading...

Loading...