Maintenance - 500h

ICC1300-1EN3.pdf2011-10-10

Maintenance - 500h

Park the roller on a level surface.

The engine must be switched off and the

parking brake activated when checking or

adjusting the roller, unless otherwise specified.

Park the roller on a level surface.

The engine must be switched off and the

parking brake activated when checking or

adjusting the roller, unless otherwise specified.

Ensue that there is good ventilation (air

extraction) if the engine is run indoors. Risk of

carbon monoxide poisoning.

Ensue that there is good ventilation (air

extraction) if the engine is run indoors. Risk of

carbon monoxide poisoning.

Drum - oil level

Inspection - filling

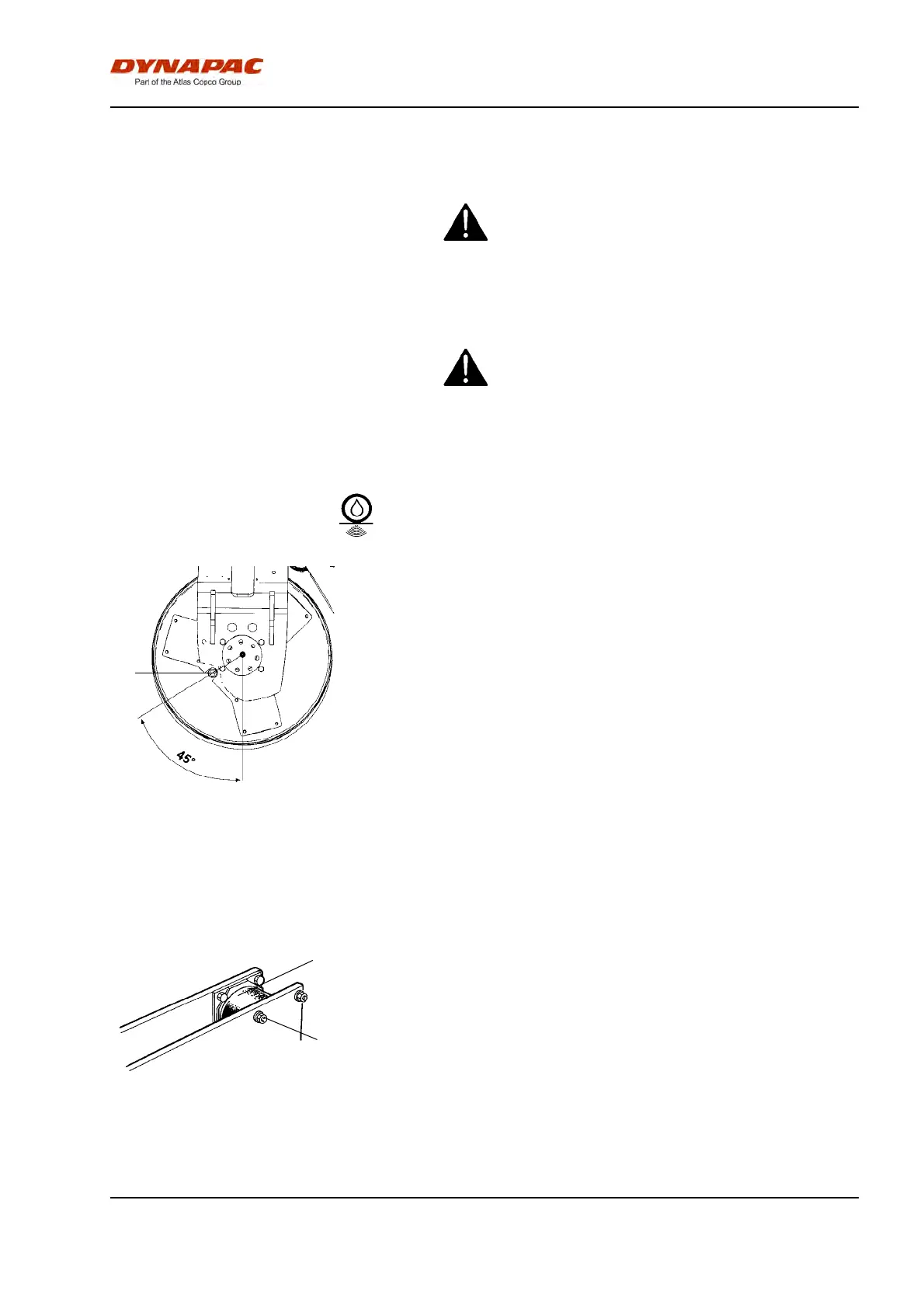

Fig. Drum, drive side

1. Oil plug

1

Run the roller slowly until the oil plug (1) is aligned

with the semicircular recess in the drum suspension.

Unscrew the plug and check that the oil level reaches

up to the bottom of the hole. Top up with new oil if

necessary. Use oil as specified in the lubricants

specification.

Clean the magnetic oil plug (1) from any metallic

residue, and refit the plug.

Rubber elements and attachment screws

Check

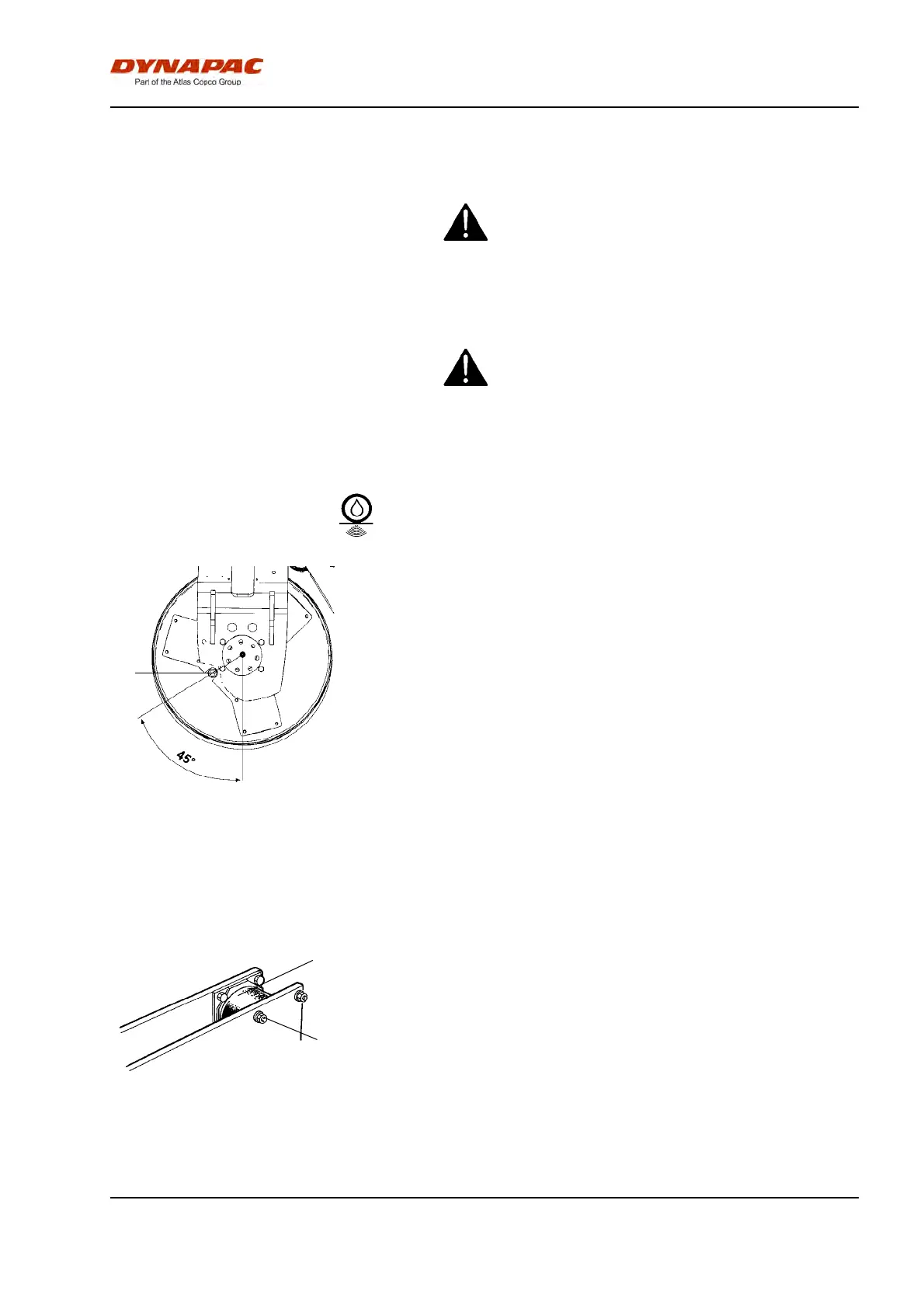

Fig. Drum, vibration side

1. Rubber element

2. Attachment screws

2

1

Check all rubber elements (1). Replace all elements

where more than 25% of the elements on one side of

the drum have cracks deeper than 10-15 mm (0.4-0.6

in).

Check using a knife blade or pointed object.

Check also that the attachment screws (2) are

tightened.

79

Loading...

Loading...