12

WLT6000-1EN1

Valve clearance inspection and adjustment

must be performed with the engine cold.

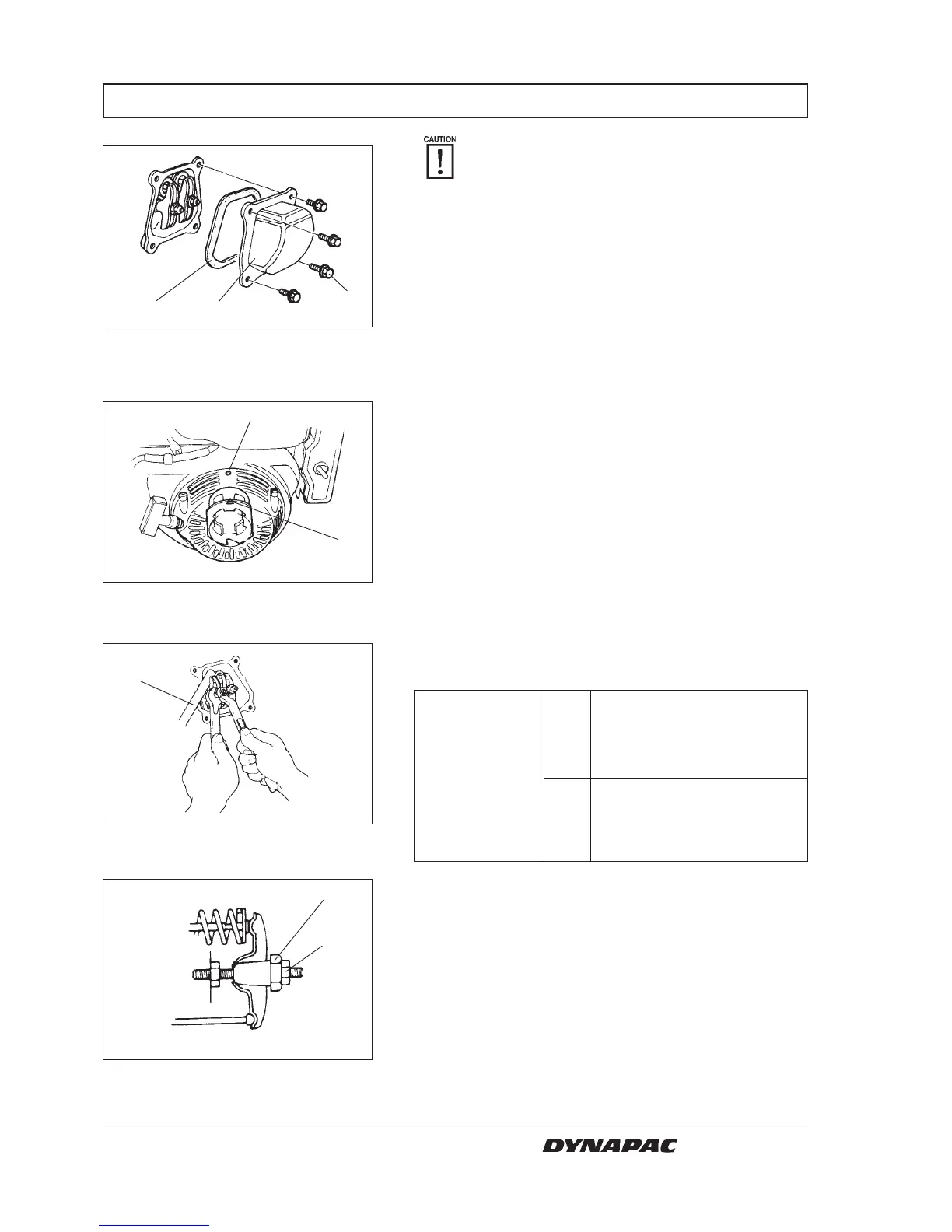

1. Remove the four cylinder bolts, cylinder head cover

and gasket.

VALVE CLEARANCE LT 7000

1

23

Fig. 19 Valve

1. Bolts

2. Cylinder head cover

3. Gasket

Fig. 21 Valve adjustment

1. Feeler gauge

1

Fig. 22 Valve adjustment

1. Rocker arm pivot

2. Rocker arm pivot lock nut

2

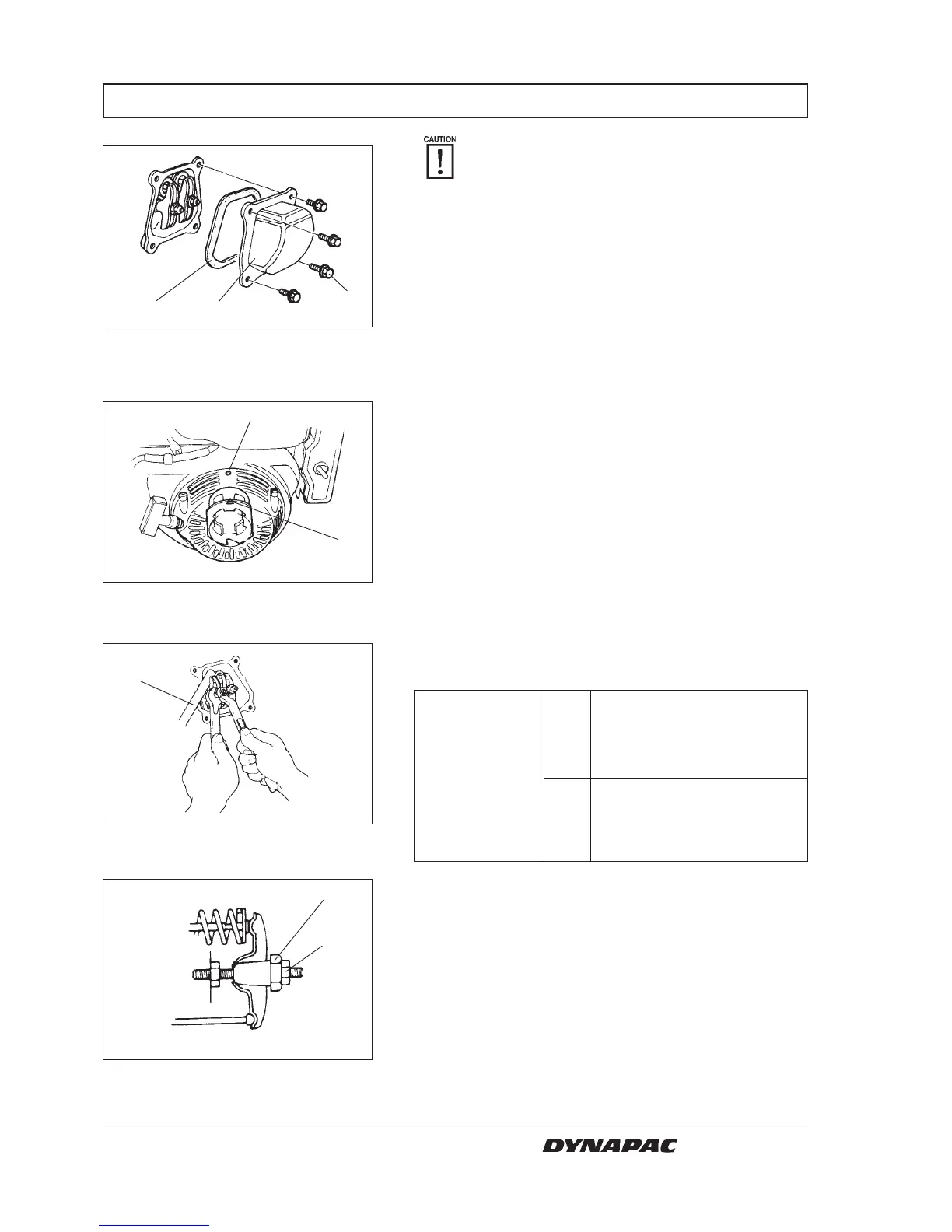

Fig. 20 Mark

1. Triangular mark

2. Top hole

2

1

1

2. Set the piston at top dead center of the compression

stroke (both valves fully closed). The triangular

mark on the starter pulley will align with the top hole

on the fan cover when the piston is at top dead

center of the compression or exhaust stroke.

In 0,15 ± 0,02 mm

(0,006 ± 0,001 in)

Standard

valve

clearance

Ex 0,20 ± 0,02 mm

(0,008 ± 0,001 in)

3. Insert a feeler gauge between the rocker arm and

valve to measure valve clearance.

4. IF adjustment is necessary, proceed as follows:

1. Hold the rocker arm pivot and loosen the rocker

arm pivot lock nut.

2. Turn the rocker arm pivot to obtain the specified

clearance.

3. Retighten the rocker arm pivot lock nut while

holding the rocker arm pivot.

4. Recheck valve clearance after tightening the

rocker arm pivot lock nut.

W000021A

W000022A

W000023A

W000024A

Loading...

Loading...