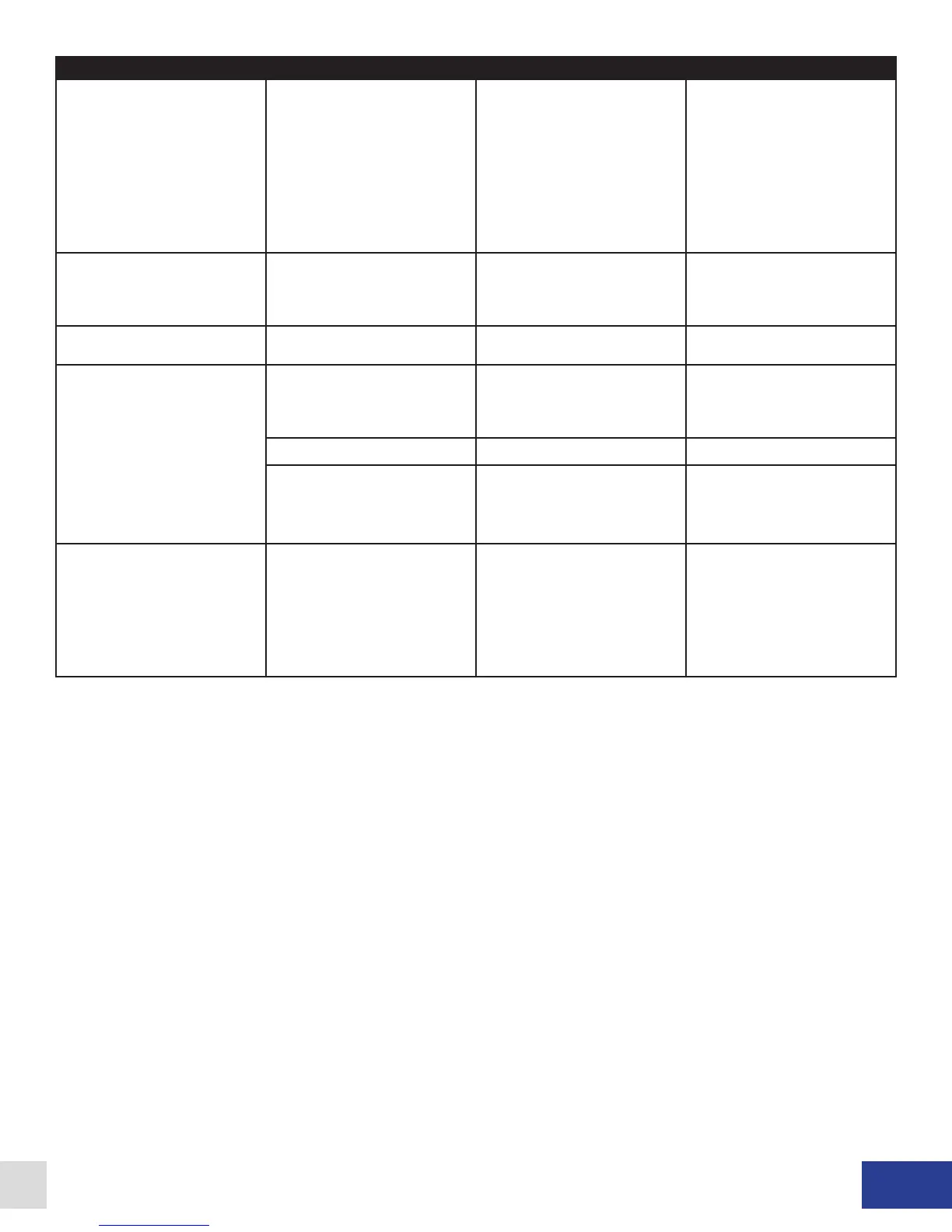

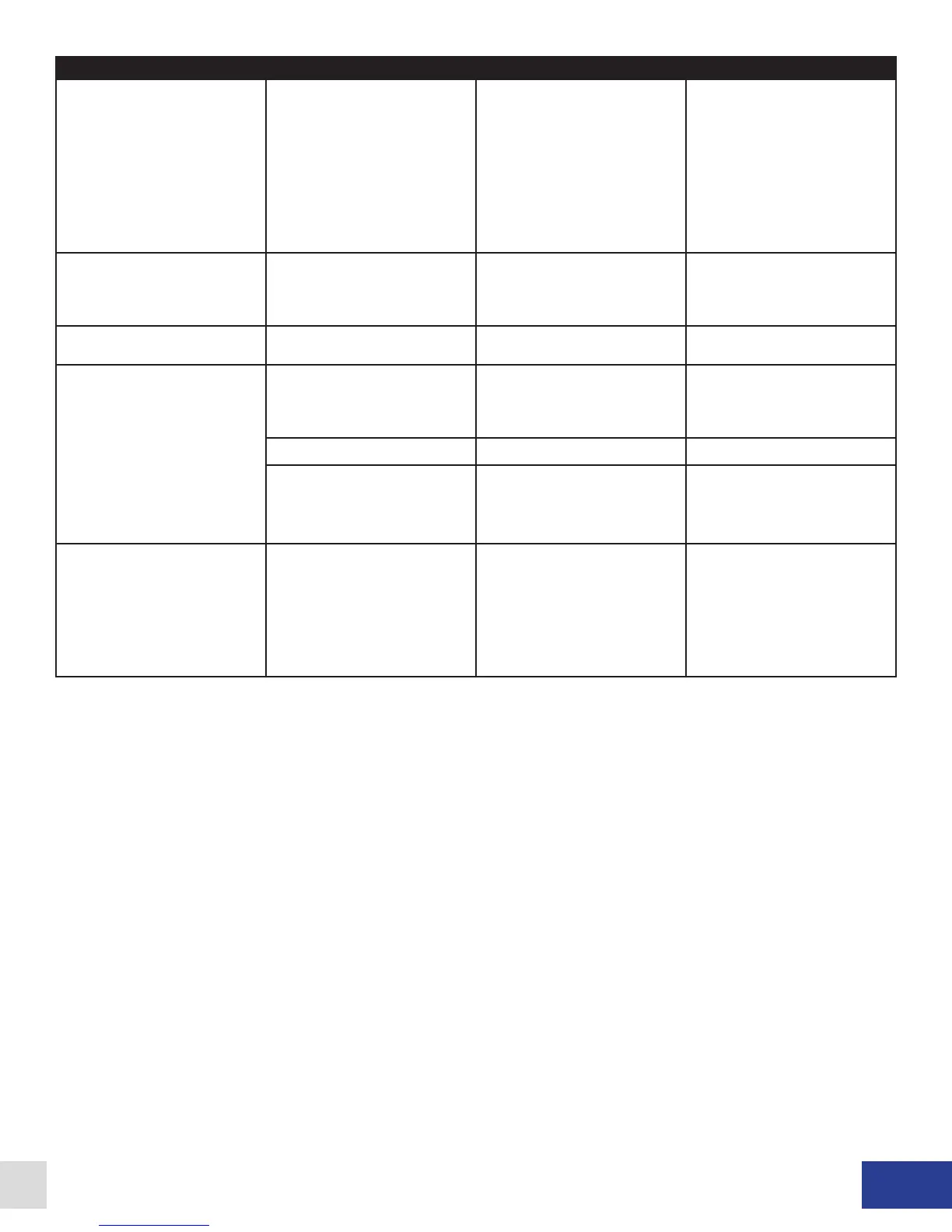

Faults/Troubleshooting

Fault/Problem Cause Wall Mount Solution Rack Mount Solution

Coolant P/F fault showing in

LCD display.

The dynamometer cooling

system pressure (or ow) has

dropped below the setpoint of

the coolant pressure (or ow)

switch (closed = safe to run).

Verify the operation of the

various components making

up the dyno cooling system.

Check functionality of coolant

pressure (or ow) switch and

its connections to TB4-1 and

TB4-2. If a pressure (or ow)

switch is not installed, a jumper

should be installed across

these terminals.

Verify the operation of the

various components making

up the dyno cooling system.

Check functionality of coolant

pressure (or ow) switch and

its connections to AUX-3 and

AUX-8. If a pressure (or ow)

switch is not installed, a jumper

should be installed across

these terminals.

I Feedback Err fault showing in

the LCD display.

The sensed current ow is

different than the system

expected.

If using a low inductance coil,

try installing jumper JP2.

Contact Dyne Systems.

If using a low inductance coil,

try installing jumper JP2.

Contact Dyne Systems.

Current Reversed fault showing

in LCD display.

Current transducer wiring is

incorrect.

Contact Dyne Systems Contact Dyne Systems

No Field Current fault showing

in LCD display.

Defective eld coil, or wiring to

the eld coil.

Verify eld coil integrity and its

connections to the PAU at

TB6-3 and TB6-4.

Verify eld coil integrity and

its connections to the PAU at

appropriate connector

(see Fig. 5.6 or Fig. 5.7).

Main PAU fuses open. Not Applicable Check fuses (FU1, FU2).

Defective eld power

transformer

Verify operation of eld power

transformer and its connections

to TB6-5, TB6-6, TB6-7 and

TB6-8.

Verify operation of eld power

transformer and its connections

at appropriate connector

(see 5.6 or Fig. 5.7).

Current OverCmd fault showing

in LCD display.

The applied current command

signal has exceeded 110%.

The nominal current

reference range is 0 to 100%.

Commanded currents of 101%

are allowed indenitely, 102%

- 109% for approximately 10

seconds, 110% (or greater) are

not allowed.

The nominal current

reference range is 0 to 100%.

Commanded currents of 101%

are allowed indenitely, 102%

- 109% for approximately 10

seconds, 110% (or greater) are

not allowed.

Table 8.1 - Wall and Rack Mount Troubleshooting Guide

Dyne Systems • DS820F PAU

DPD-001-04B • © Copyright Dyne Systems, Inc.

27

Loading...

Loading...