128

K000000000EJ 023826A0 100714

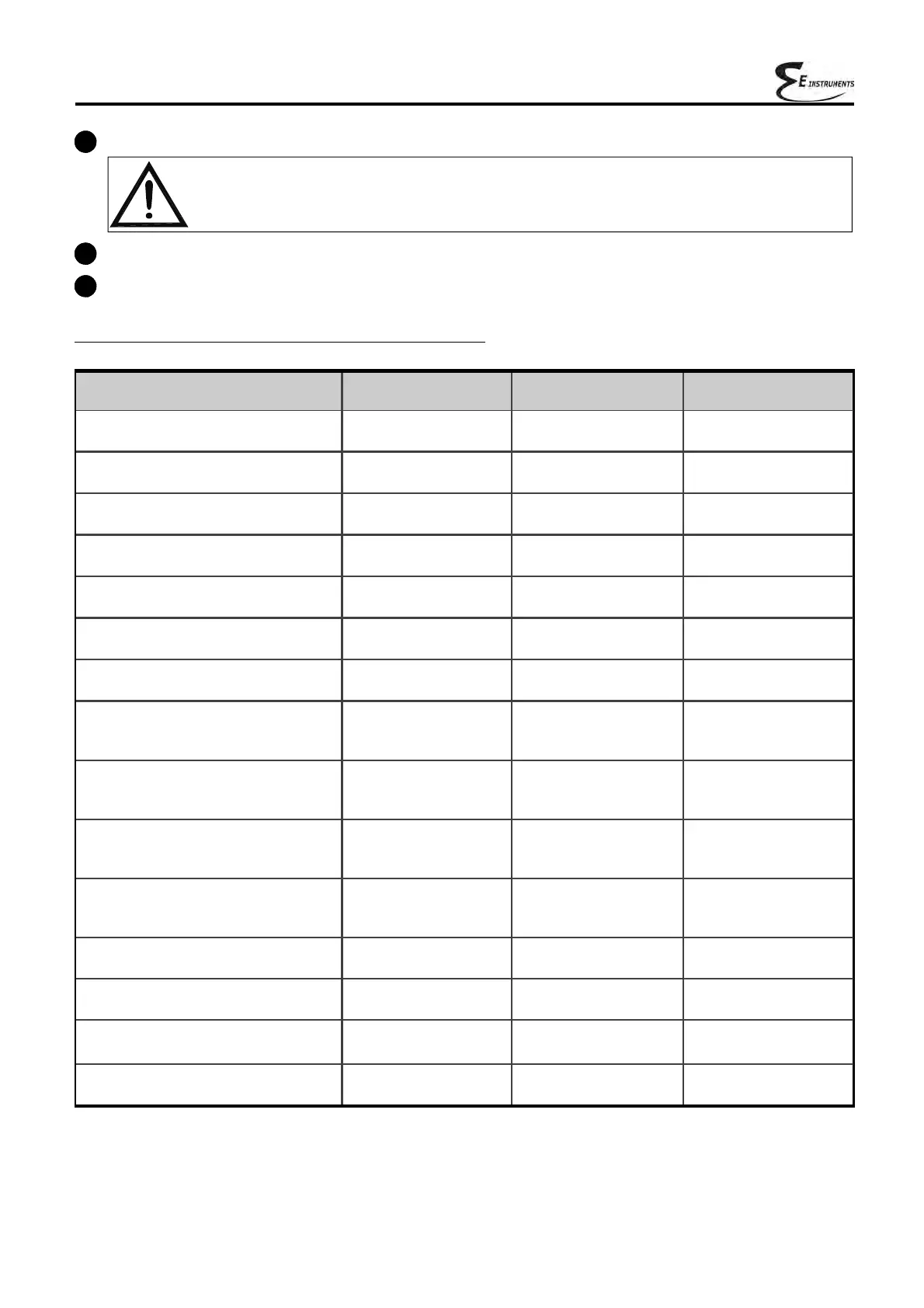

Turn on the instrument to check the new sensor works correctly through the menu "Sensor Troubleshooting".

It is normal if a newly installed sensor gives a 'current error'

: it is necessary to wait some time, so that the sensor

polarization can settle. The table here below shows the minimum settling time for each sensor.

Note:

(1)

2 hours’ settling time is recommended.

(2) 48 hours’ settling time is recommended; should the sensor be equipped with an external polarization battery, the

settling time is reduced down to 2 hours.

(3) 1/2-Hour settling time is recommended.

CODICE GAS RILEVATO POSITION

TEMPO DI

ASSESTAMENTO

Flex-Sensor O

2

Cod. AACSE11

O

2

Oxygen

S1

2 hours

(1)

Flex-Sensor O

2

Cod. AACSE15

O

2

Oxygen

S1

2 hours

(1)

Flex-Sensor CO+H

2

Cod. AACSE12

CO

Carbon Monoxide

S2

2 hours

(1)

Flex-Sensor CO high (H

2

Comp)

Cod. AACSE20

CO

Carbon Monoxide

S2/S3/S4

2 hours

(1)

Flex-Sensor NO

Cod. AACSE10

NO

Nitrogen Oxide

S3

48 hours

(2)

Flex-Sensor NO

2

Cod. AACSE14

NO

2

Nitrogen Dioxide

S2/S3/S4

2 hours

(1)

Flex-Sensor SO

2

Cod. AACSE13

SO

2

Sulphur Dioxide

S2/S3/S4

2 hours

(1)

Flex-Sensor CO

100,000 ppm

Cod. AACSE17

CO

Carbon Monoxide

S2/S3/S4

2 hours

(1)

Flex-Sensor CO

20,000 ppm

Cod. AACSE18

CO

Carbon Monoxide

S2/S3/S4

2 hours

(1)

FLEX-Sensor CxHy

0-5.00% vol. referred to CH4

Cod. AACSE23

CxHy

Unburned hydrocarbons

S4

1/2 hour

(3)

Flex-Sensor CO+H

2

low range

Cod. AACSE24

CO

Carbon Monoxide

S2

2 hours

(1)

Flex-Sensor NO low range

Cod. AACSE25

NO

Nitrogen Oxide

S3

48 hours

(2)

Flex-Sensor NO

2

low range

Cod. AACSE26

NO

2

Nitrogen Dioxide

S2/S3/S4

2 hours

(1)

Flex-Sensor SO

2

low range

Cod. AACSE28

SO

2

Sulphur Dioxide

S2/S3/S4

2 hours

(1)

Flex-Sensor CO

2

Cod. AACSE29

CO

2

Carbon Dioxide

S3/S4

2 hours

(1)

9

Reconnect the sensor (See point 3).

10

Close the back door of the sensor compartment again, and tighten screws again (See point 1).

8

Rotate the sensor clockwise until hearing a click (See point 4).

While rotating the sensor, take care not to exert any pressure onto the printed circuit

above: exert pressure onto the plastic body only.

Loading...

Loading...