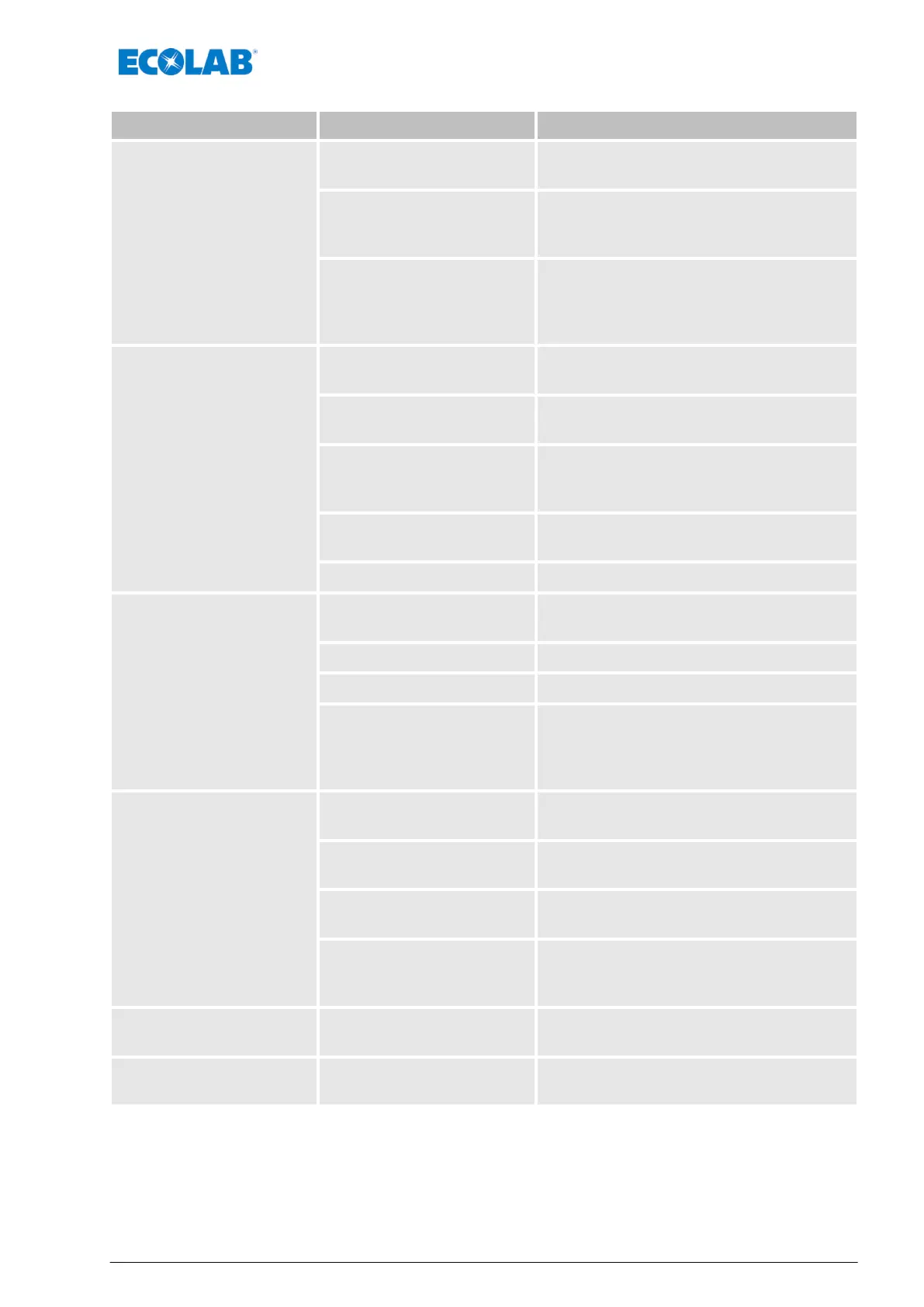

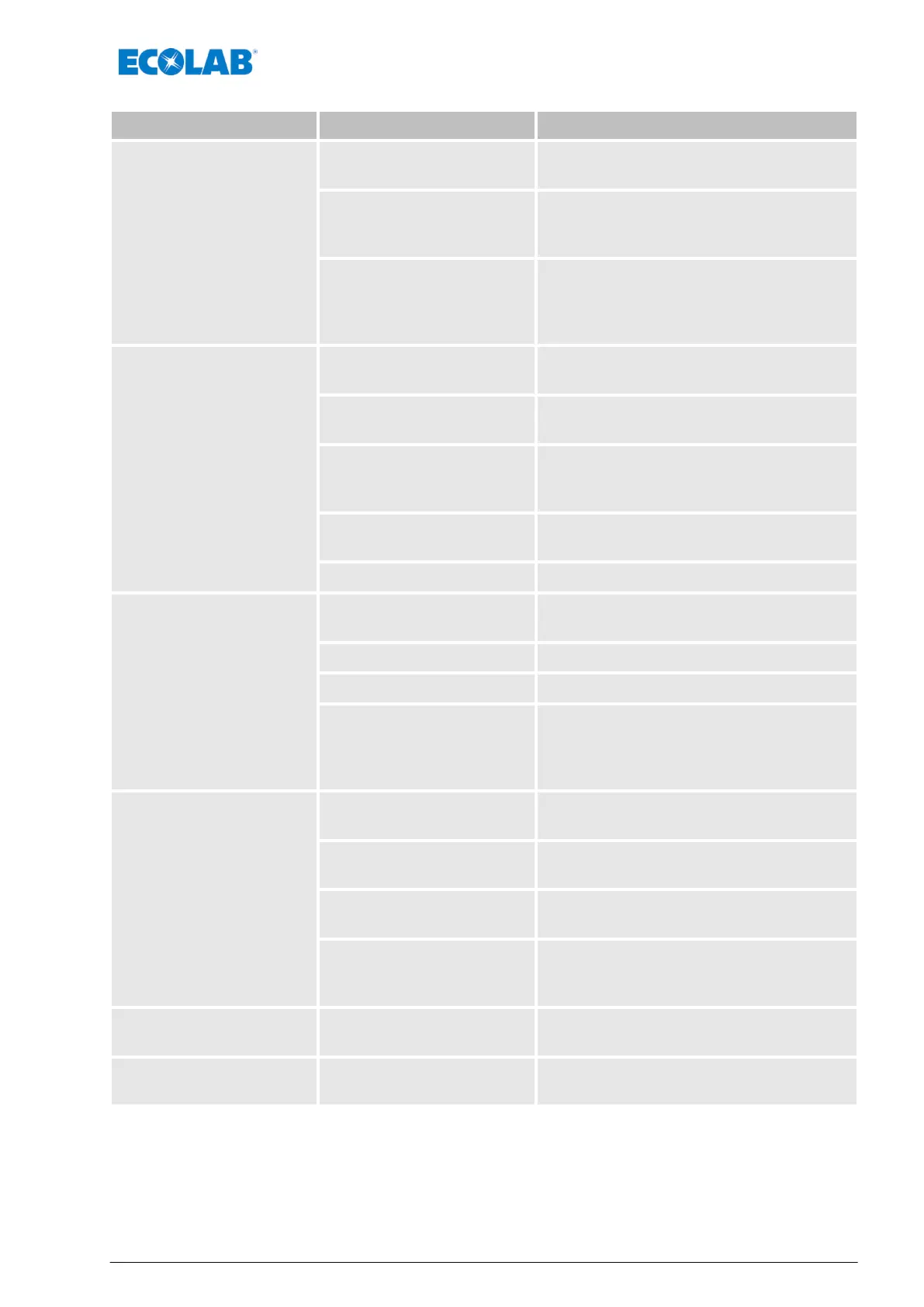

Fault description Cause Remedy

No metering - dosing

pump rattles.

Counter-pressure too high. Reduce pressure at pressure retention

valve.

Discharge line and/or valve

blocked.

Disassemble and clean valve(s) and

lines on the pressure side, and clear

blockage.

Actual counter-pressure in

equipment (= total of all

pressure losses) is too

high.

Determine and calculate pressure loss of

entire system, and compare/check pump

system layout

Dosage is too small. Dosage setting incorrect.

increase output (

Ä

Chapter

6.1.1 ‘Setting the flow rate’ on page 33).

Suction line leaking. Check/service connections and suction

line, and replace if necessary.

Dosage counter-pressure

too high.

Check actual counter-pressure (= total of

all pressure losses) and valves and lines

on pressure side - clear bottlenecks.

Viscosity setting incorrect.

Check jumper position and viscosity (

Ä

‘

Setting’ on page 33).

Wrong pump head. Install correct pump head.

Dosing pump does not

work.

Operating voltage too low /

not on.

Check operating voltage / control.

Power cord damaged. Replace power cord.

Motor / electronics faulty. Replace pump module (II).

Switched-mode power

supply (SMPS) faulty (in

230 V back cover

modules).

Check SMPS: OK = LED lights up,

replace SMPS if necessary.

Pump doesn't draw. Suction line leaking. Check and service suction line and

connections, and replace if necessary.

Storage container empty /

fill level too low.

Fill / replace storage container.

Air in pump head and

suction line.

Briefly reduce dosage counter-pressure

and bleed pump.

Sediment, valves sticking

or blocked.

Flush pump head via suction line;

remove and clean dispensing head, or

replace if needed.

Pump head leaking. Pump head mounting

screws loose.

Tighten pump head screws crosswise

(M = 3,75 Nm).

Medium leaks from

diaphragm failure drain.

Diaphragm is torn. Replace pump head and diaphragm.

Malfunctions / Repairs

43 Rev. 5-06.2018

Loading...

Loading...