A705-40-880 Issue B

Page 36 © Edwards Limited 2011. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

5.3 Check the gearbox oil-level and fill the gearbox with oil (if

necessary)

Note: If you need to pour oil into the gearbox frequently, or if there is a sudden loss of a large amount of oil, this

may indicate that the pump has a fault. In these circumstances, we recommend that you shut down the

pump as soon as possible and contact your supplier or Edwards for advice.

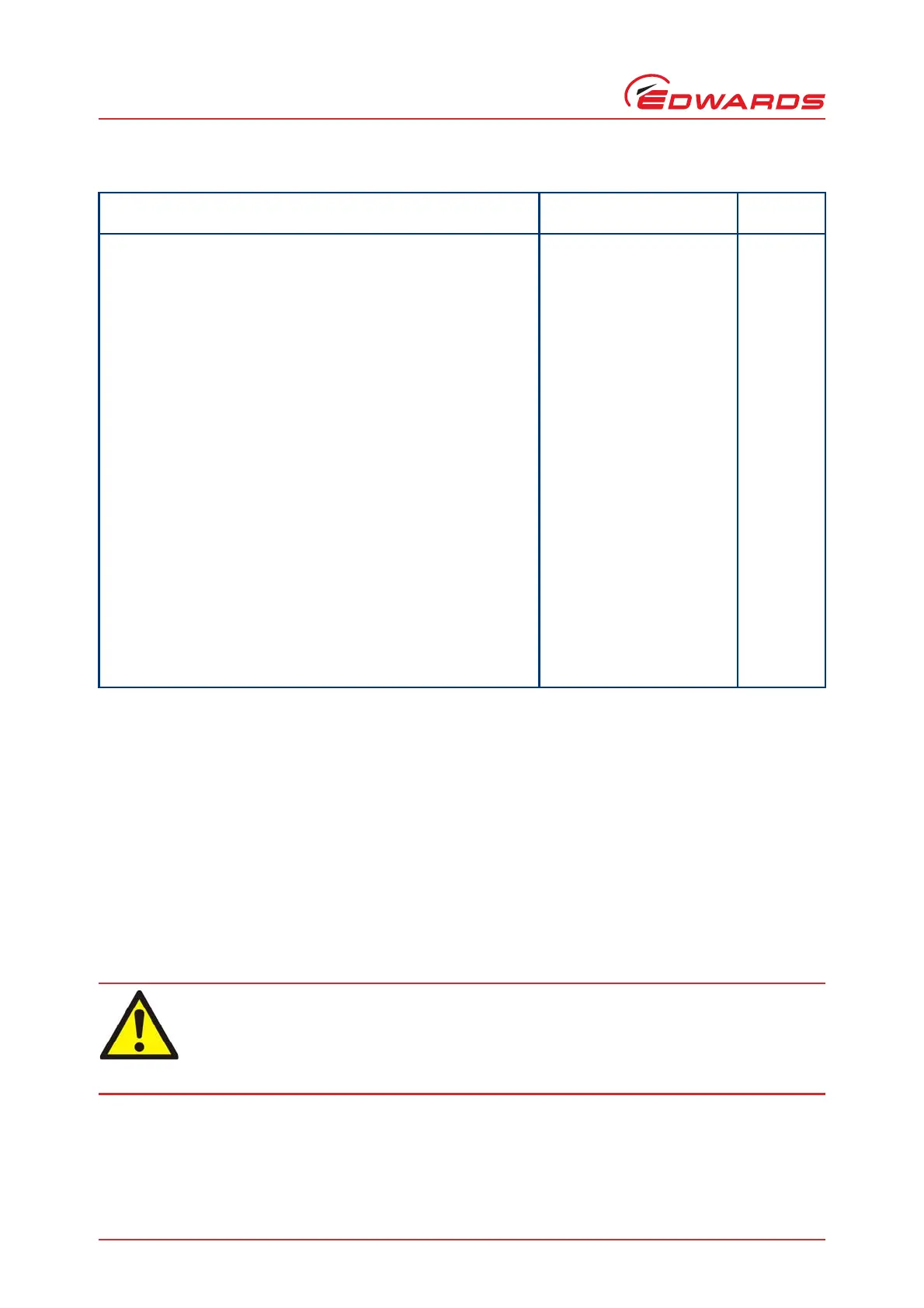

Table 14 - Maintenance plan

Operation Frequency

Refer to

Section

Check the gearbox oil level and fill the gearbox with oil (if

necessary)

Weekly (non-flammable

processes)

Daily (flammable processes)

5.3

Check the shaft-seals purge supply Weekly 5.4

Remove the inlet filter After 1 month of operation 5.5

Inspect the pipelines and connections 3 monthly 5.6

Inspect the pressure relief valve and replace the hinge bushes, flap

and 'O' rings (if necessary)

*

*

EDP250 and EDP400 only.

Yearly or when necessary 5.7

Change the pump oil and clean the oil-level sight-glasses

†

†

You will need a Routine Maintenance Kit to do these maintenance operations.

Yearly or when contaminated,

whichever occurs first

‡

‡

If the gearbox oil is contaminated (indicated by a change in colour of the oil, for example, water

contamination will turn the oil a white colour), you must change the oil. You may be able to remove the

contaminants from the oil by filtration. For maximum pump reliability, we recommend that you change the

gearbox oil when you relubricate the rotor bearings: refer to Table 15 in Section 5.9.

5.8

Relubricate/inspect the rotor bearings

†

When necessary

**

**

The frequency of maintenance depends on the operating temperature of the pump: see Section 5.9.

5.9

Check the coolant level and refill if necessary Yearly 5.10

Flush the pump with cleaning solution When necessary 5.11

Clean the cooling system

†

Yearly or when necessary 5.12

Overhaul the pump

††

††

You must have an Upper Bearing Kit, a Lower Bearing Kit, a Swept Volume Kit and (for the EDP250 and

EDP400 only) a Swing Pressure Relief Valve Overhaul Kit to overhaul the pump.

3 yearly 5.13

Replace the pressure relief valve

*

When necessary 5.14

Inspect the torque limiter

‡‡

‡‡

Pumps with a torque limiter only.

Yearly 5.15

Inspect the torque limiter coupling element Yearly

Replace the pump-motor and drive coupling element

***

***

You must have a new pump-motor and a Motor Fitment Kit to do this maintenance operation.

When necessary

Fit a replacement service module When necessary 5.16

The gearbox may be pressurised. To remove the oil filler-plug, undo it slowly until the vent hole

is visible, allow the gearbox to vent to atmosphere to reduce the pressure in the gearbox, then

fully undo and remove the oil filler-plug. If you do not, hot (up to 90 °C) oil may be ejected under

pressure from the gearbox and cause injury.

Loading...

Loading...