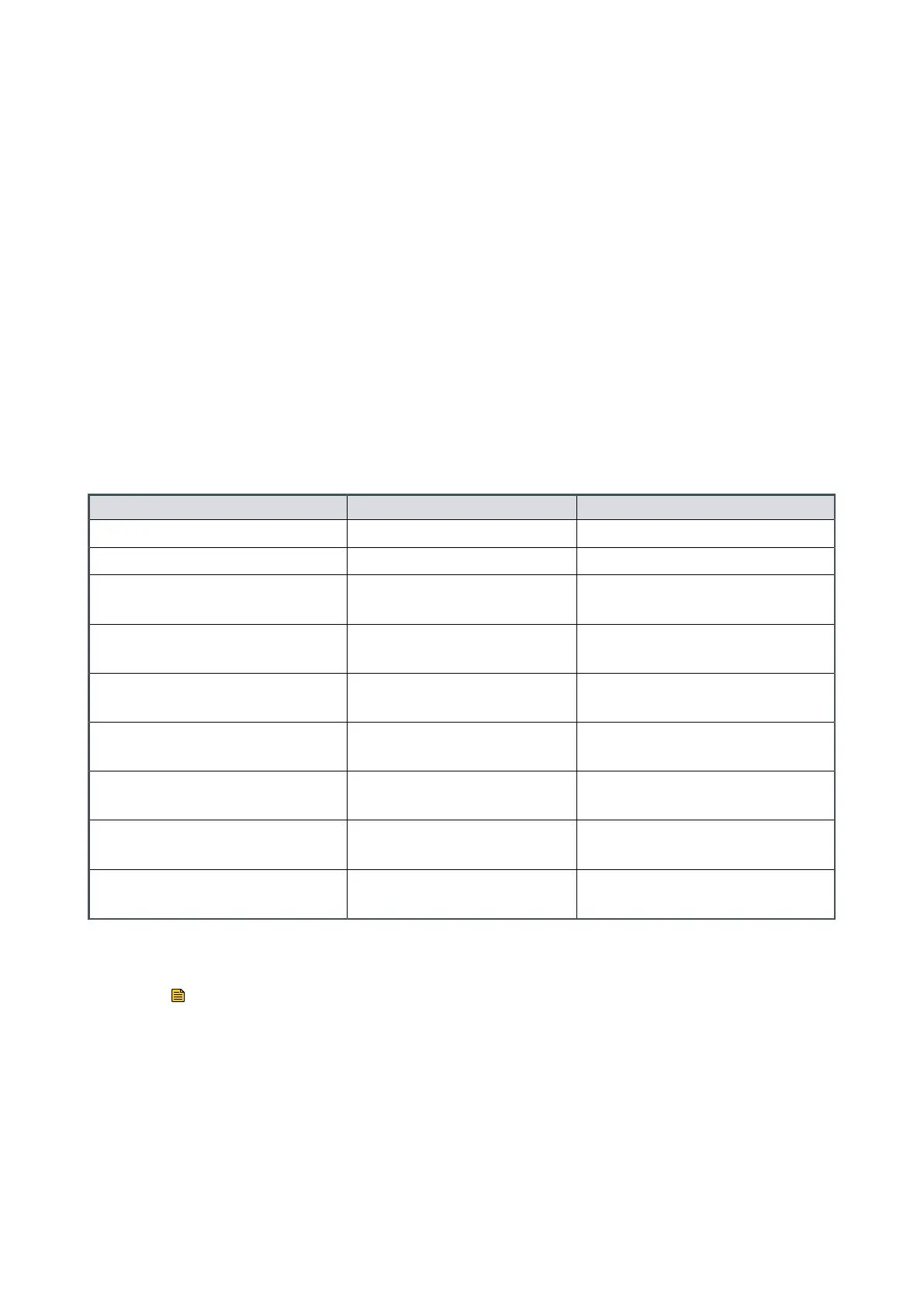

6.2 Maintenance plan

The plan shown in Table: Maintenance plan on page 37 details the roune maintenance

operaons necessary to maintain the pump in normal use. Instrucons for each

operaon are given in the secon shown.

More frequent maintenance may be required if the pump is used to process corrosive or

abrasive gases and vapours, in these circumstances, we recommend you to replace the

pump seals every year. If necessary, adjust the maintenance plan according to

experience.

When carrying out maintenance on the pump, use our spares and maintenance kits,

these contain all the components necessary to complete maintenance operaons

successfully. The item numbers of the spares and kits are given in Spares.

Examine the condion of any external accessory, lters or traps (if ed) when carrying

out maintenance on the pump. Refer to the instrucons supplied with these accessories

for the necessary maintenance procedures.

Maintenance plan

Operaon Frequency Refer to secon

Check the oil level As required; at least monthly Check the oil level on page 37

Replace the oil Every 3000 hours of operaon Replace the oil on page 38

Inspect and clean the inlet lter Every oil change Inspect and clean the inlet-lter

on page 38

Clean or replace the gas-ballast

lter

Yearly Clean the gas-ballast lter on

page 39

Clean the motor fan-cover and

enclosure

Yearly Clean the motor fan-cover and

enclosure on page 40

Clean and overhaul the pump Every 15000 hours of

operaon

Clean and overhaul the pump on

page 40

Replace the run capacitor Every 4 years Replace the run capacitor and test

the motor on page 40

Test the motor condion Every 15000 hours of

operaon

Replace the run capacitor and test

the motor on page 40

Fit new blades Every 30000 hours of

operaon

Fit new blades on page 40

6.3 Check the oil level

Note:

1. If required, it is possible to check the oil

‑

level while the pump is operang, however

the pump must be switched o. Isolate the pump and other components in the pumping

system from the electrical supply before pouring oil into the pump.

2. Do not mix hydrocarbon lubricants with PFPE or vice versa. If the oil is mixed, drain

and rell with clean oil as described in Replace the oil on page 38.

Refer to Figure: General view of the pump on page 11 for the items in brackets.

Page 37

A34310880_T - Maintenance

Loading...

Loading...