4.6.2 Connect the pump inlet

CAUTION: O-RING SAFETY

Risk of damage t

o the equipment. For iXM200 and iXM3000 variants, do not use a

trapped O‑ring or centering ring for installaon. Use 8 half claw clamps to aach inlet

piping and ghten it to a torque of 5.0 Nm.

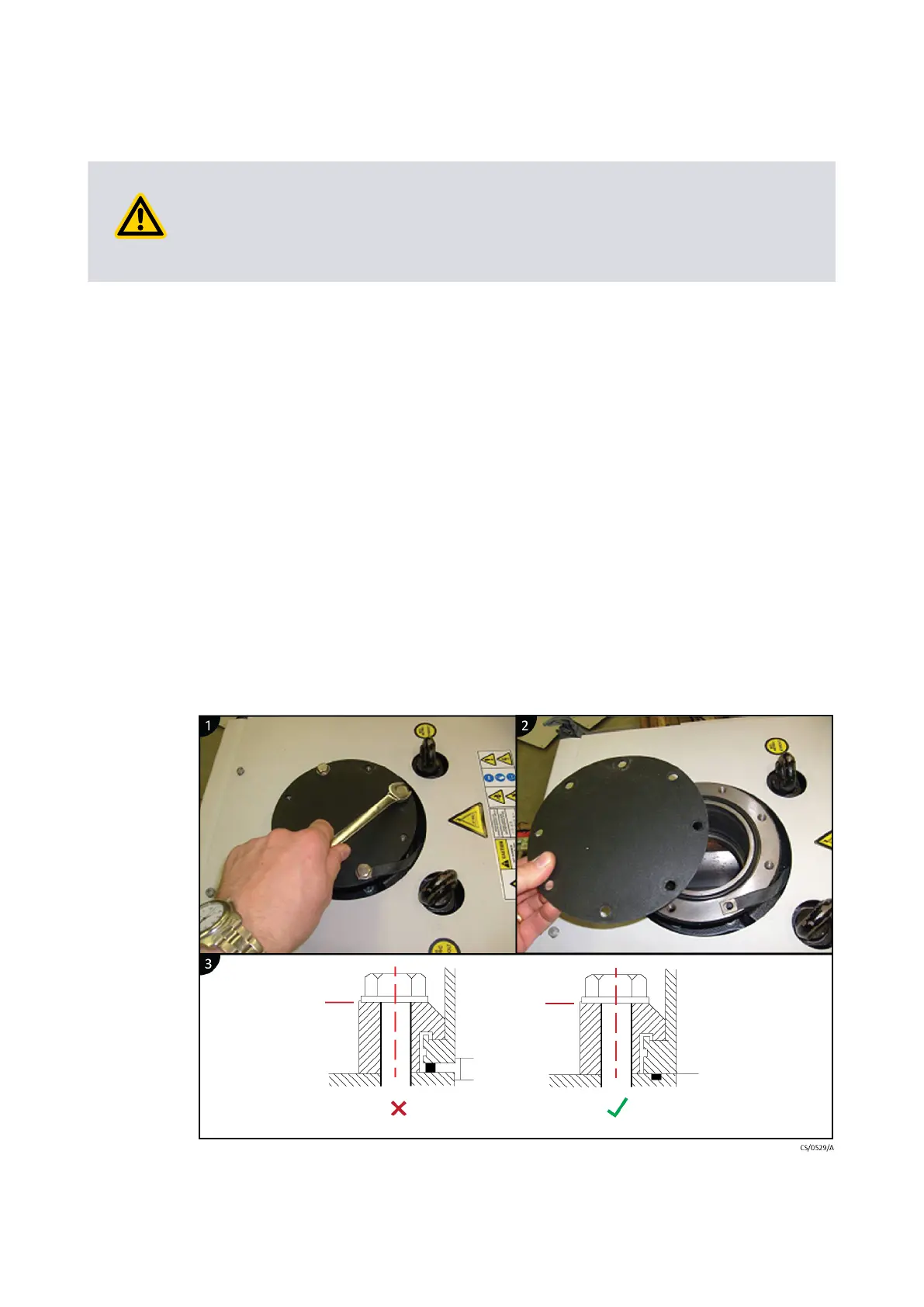

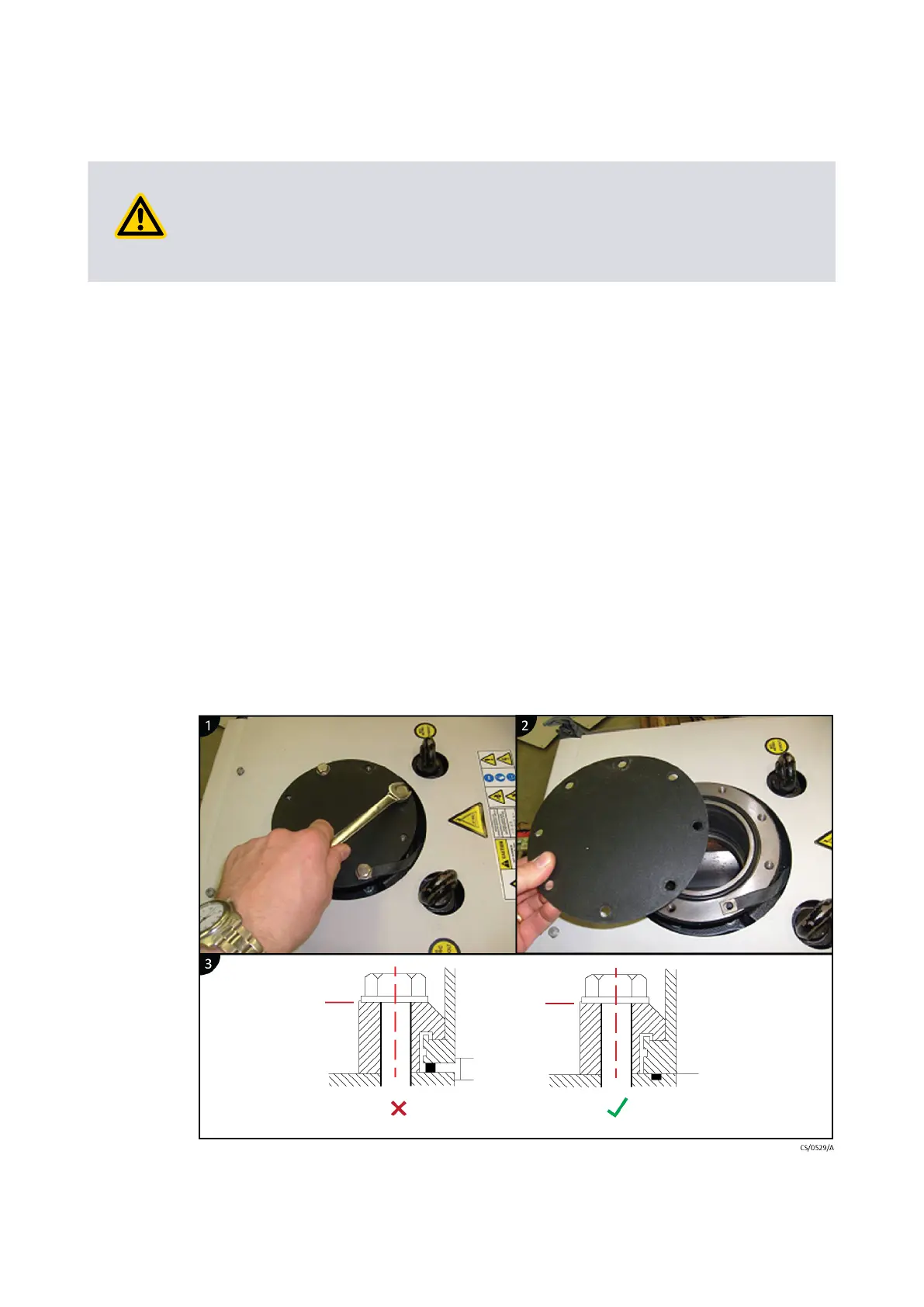

1. Remove the temporary cover or blanking plate from the inlet of the system. Do not

drop screws, tools etc. into the pump inlet.

A. Keep the nuts, bolts, washers and blanking plate for future use.

B. Keep the temporary cover for future use on non‑contaminated pumps only.

2. Connect the inlet ange (Figure: Front view of the system) to the vacuum system.

A. For iXM200 and iXM3000 variants, use the O‑ring (supplied) and applicable

nuts, bolts and washers (not supplied) to connect the inlet ange. The inlet

O‑ring is supplied with the pump and is installed underneath the inlet ange

cover. Refer to Figure: Connect the pump inlet (iXM200 and iXM3000).

B. For iXM600 and iXM1200 variants, use the trapped O‑ring or centre

ring(supplied) and applicable nuts, bolts and washers (not supplied) to

connect the inlet ange. Refer to Figure: Connect the pump inlet (iXM600

and iXM1200).

3. Use half claw clamps when you connect an ISO style foreline ange t

o the dry

pumping system inlet. Refer to Figure: Connect the pump inlet and Table: Half claw

clamps.

Figure 9 Connect the pump inlet (iXM200 and iXM3000)

10/2020 - ©Edwards Limited

Page 33M56635880_D

M56635880_D - Inst

allaon

Loading...

Loading...