In order to become familiar with how to recognise bearing preload aer a service, it is

recommended that the instrucons in Bearing preload familiarisaon on page 10 are

followed.

Bearing preload familiarisaon

CAUTION:

Ensure all tools are clean and free of dirt and grease to avoid contaminaon of the

rotor.

This procedure should be performed with the pump placed in the vercal posion.

1. Place the preload tool onto the inlet of the turbomolecular pump. The force probe

must be located into the centre of the pump inlet with the adjuster legs engaged

onto the magnec bearing adjuster nut Figure 4 on page 10. Supporng the

preload tool body in posion while performing the preload check is recommended.

2. Apply pressure by pushing the test plunger unl a change in preload can be

detected. Releasing the test plunger will return the preload back to its original

posion. Pressing and releasing the test plunger slowly while performing this check

is recommended.

Note:

Detecon of the bearing preload can be recognised by a disnct sound. This may be

accompanied by a sensory feel through the tool and pump body. If a change in preload

cannot be detected, it may be possible to carry on with the service but with cauon.

CAUTION:

If the pump has suered any damage (i.e. the rotor does not spin freely or quietly), it is

recommended that the service is not carried out and that the local service centre is

contacted for advice.

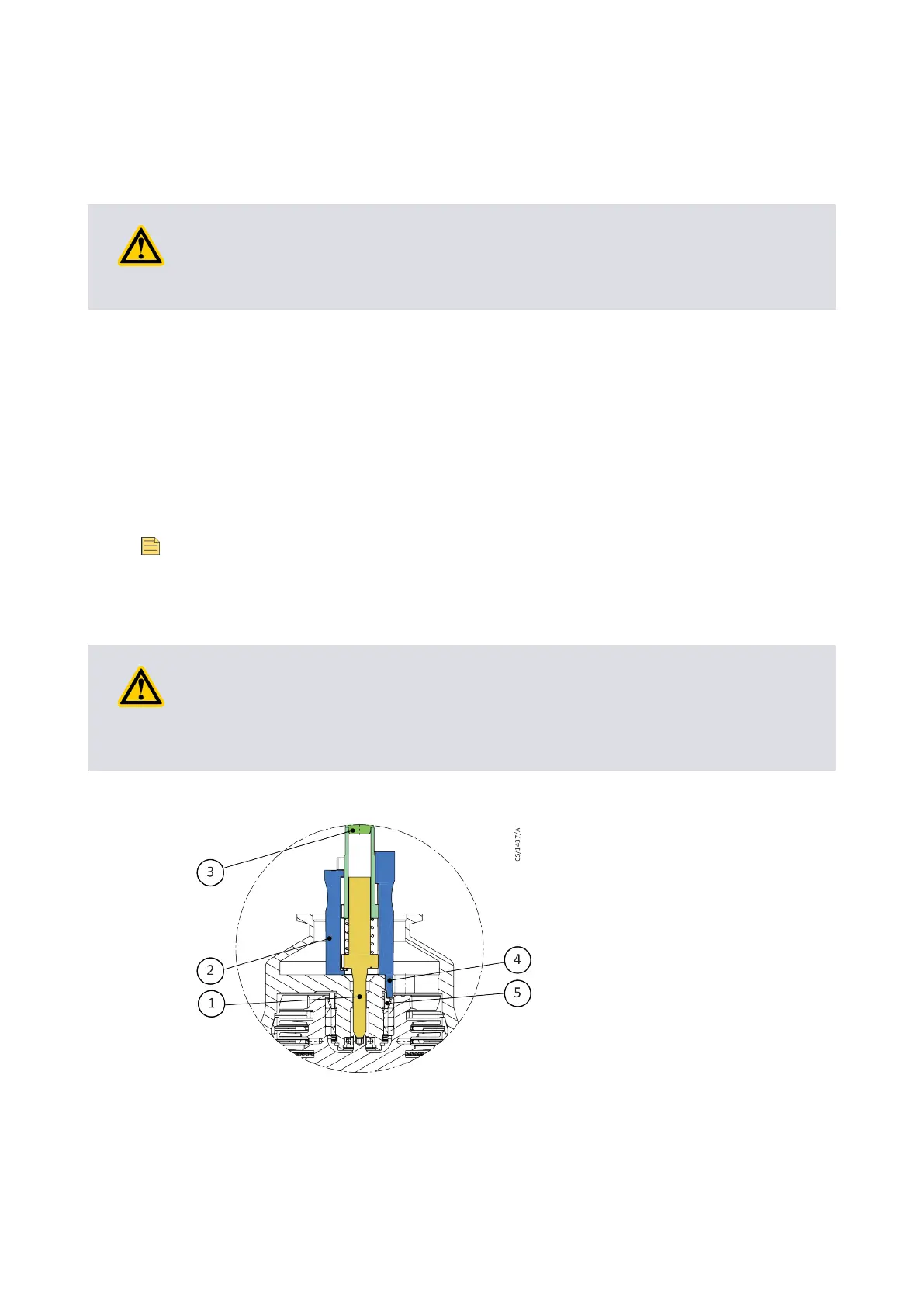

Figure 4

Locang the preload tool (NW40 variant shown)

1. Preload tool force probe

2. Preload tool body

3. Preload test plunger

4. Preload tool adjuster legs

5. Magnec bearing adjuster nut

B8G2-00-840A - Pre-service

Page 10

Loading...

Loading...