• Communicate with the nEXT85

• Perform a service reset

Note:

The oil cartridge and bearing service counter can be reset individually depending if one or

both parts have been replaced.

To conrm that the service reset has been successful, check that status LED has been reset

and is no longer ashing. Once the service counter reset has been completed, a power cycle

must be performed to complete the process.

Reset the service interval using the turbo drive standby speed control

buons

The service interval may be reset using the nEXT85 drive standby speed control buons.

1. To proceed, ensure the drive is powered. Using a suitable implement such as the

end of a ballpoint pen, press both the increase and decrease standby speed buons

simultaneously for more than 5 seconds.

Note:

This method will reset both the oil cartridge and bearing module service interval.

2. To conrm that the service reset has been successful, check that status LED has

been reset and is no longer ashing. Once the service counter reset has been

completed, a power cycle must be performed to complete the process.

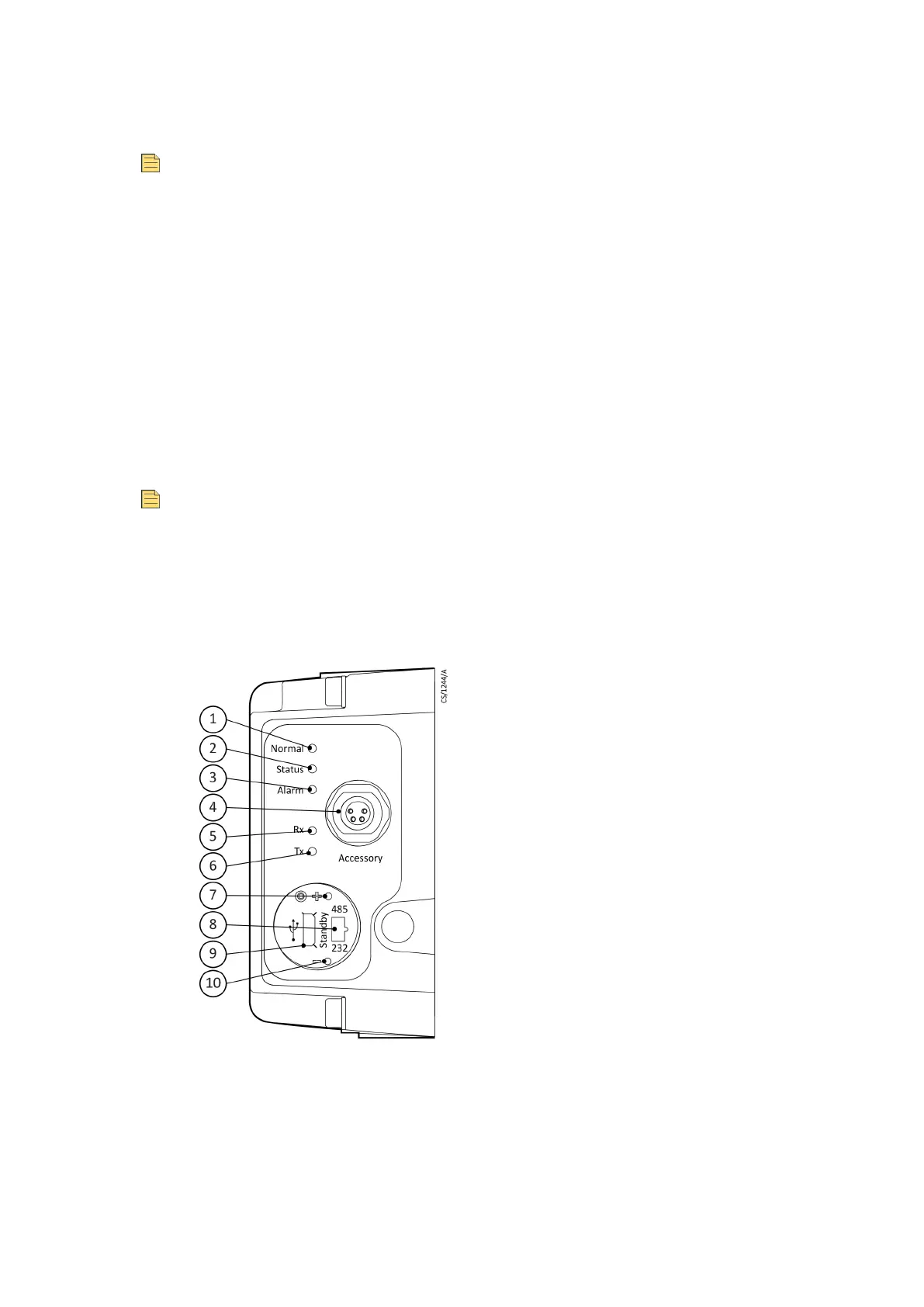

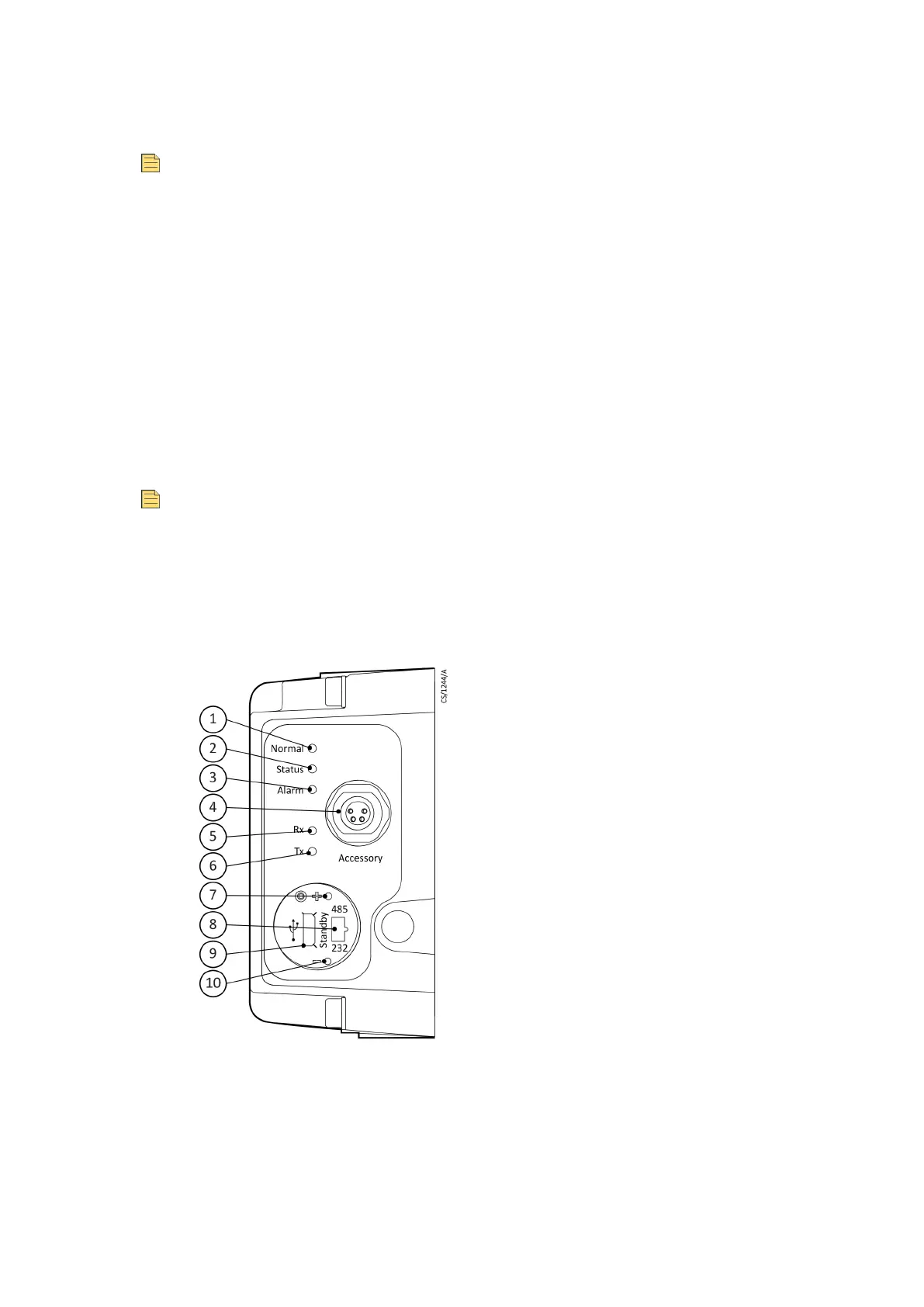

Figure 14

Motor controller status informaon

1. Normal LED

2. Status LED

3. Alarm LED

4. Accessory connector

5. Serial receive LED

6. Serial transmit LED

7. Standby speed increase buon

8. RS232/RS485 slide switch

9. USB connector

10. Standby speed decrease

buon

B8G2-00-840A - Service

Page 21

Loading...

Loading...