falls within the pass limit. When condent that the preload force has been correctly

set, proceed to Service counter reset on page 18.

4. If no preload is detected, slowly turn the preload tool body clockwise unl preload is

established in accordance with Preload check on page 9. When the preload has been

veried, measure the preload force by following the corresponding instrucons

above.

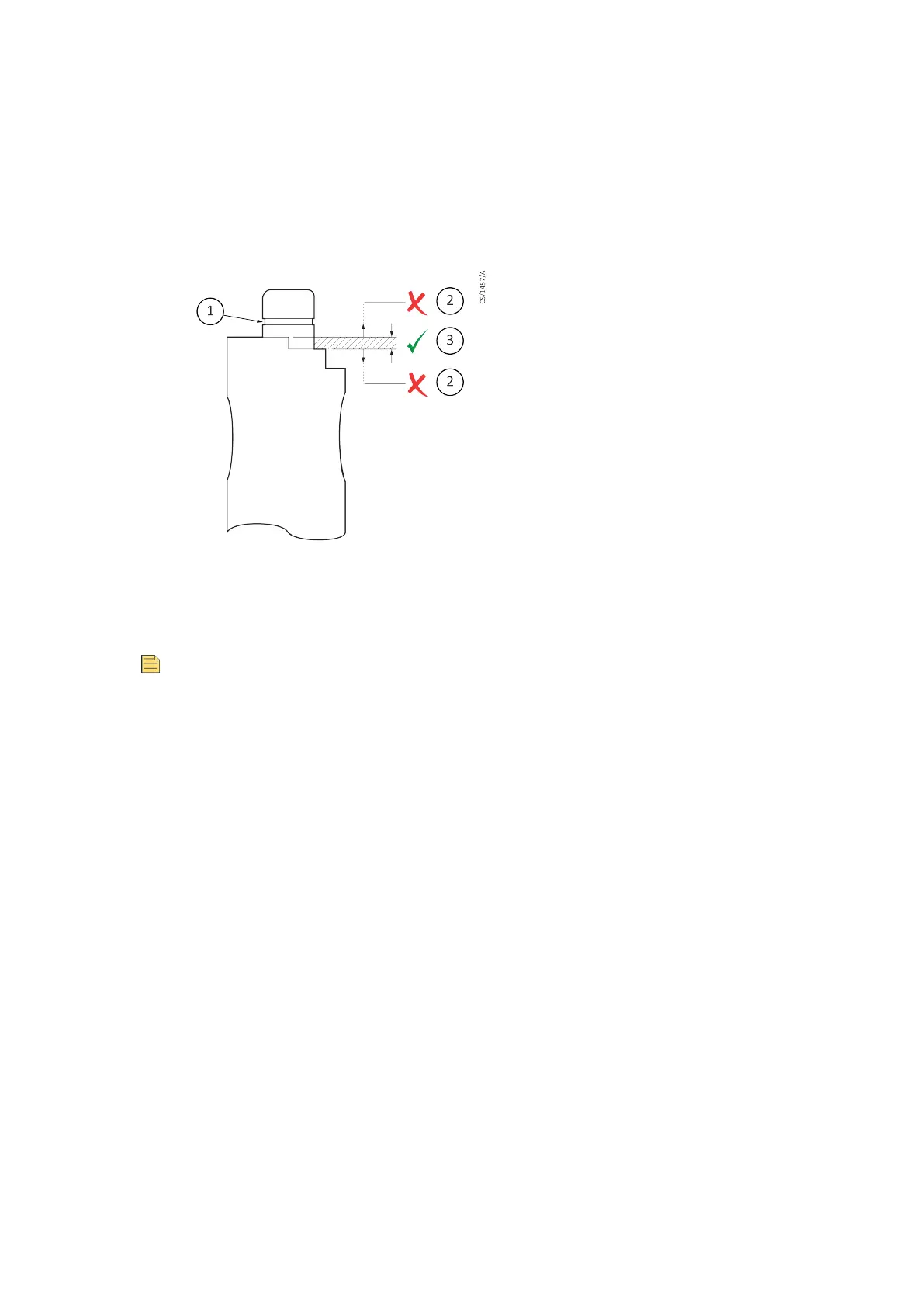

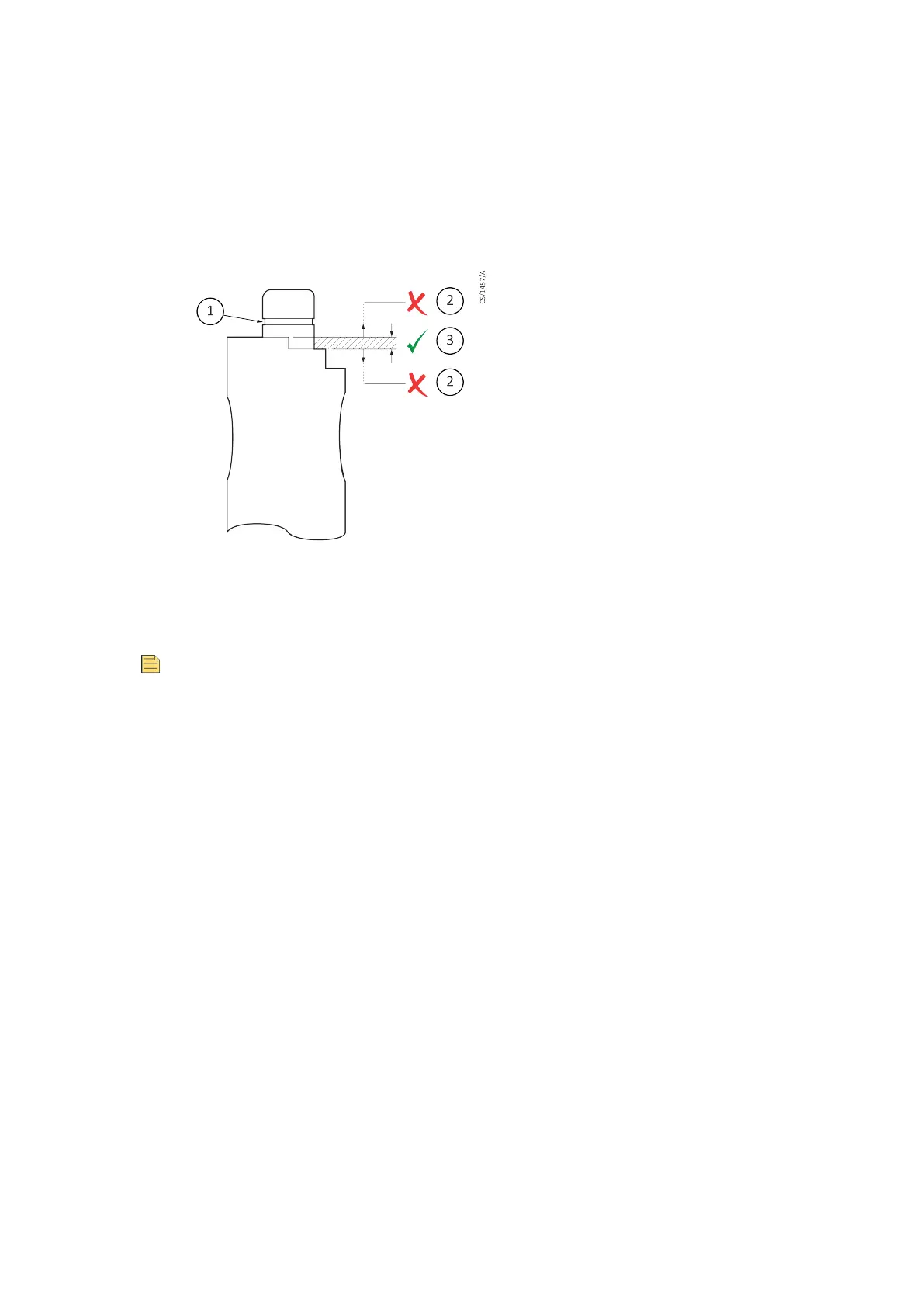

Figure 13

Preload tool (pass / fail indicaon)

1. Pass/ Fail test indicator

2. Fail

3. Pass

Note:

To check if the bearing is set to the correct preload force, the test indicator must be within

the pass limits when the preload transison occurs.

Service counter reset

Aer compleng an oil cartridge change or an oil cartridge and bearing module change, it is

important to reset the service interval in order to schedule the next service and reset the

status LED.

Depending on the set up and equipment availability, a choice of 4 opons are available to

perform a service counter reset.

Choose one of the following opons:

1. Turbo instrument controller

2. PC serial command

3. nST PC program

4. nEXT turbo controller

B8G2-00-840A - Service

Page 18

Loading...

Loading...