Note:

If replacing the oil cartridge only, go straight to Service counter reset on page 18 aer

following this instrucon.

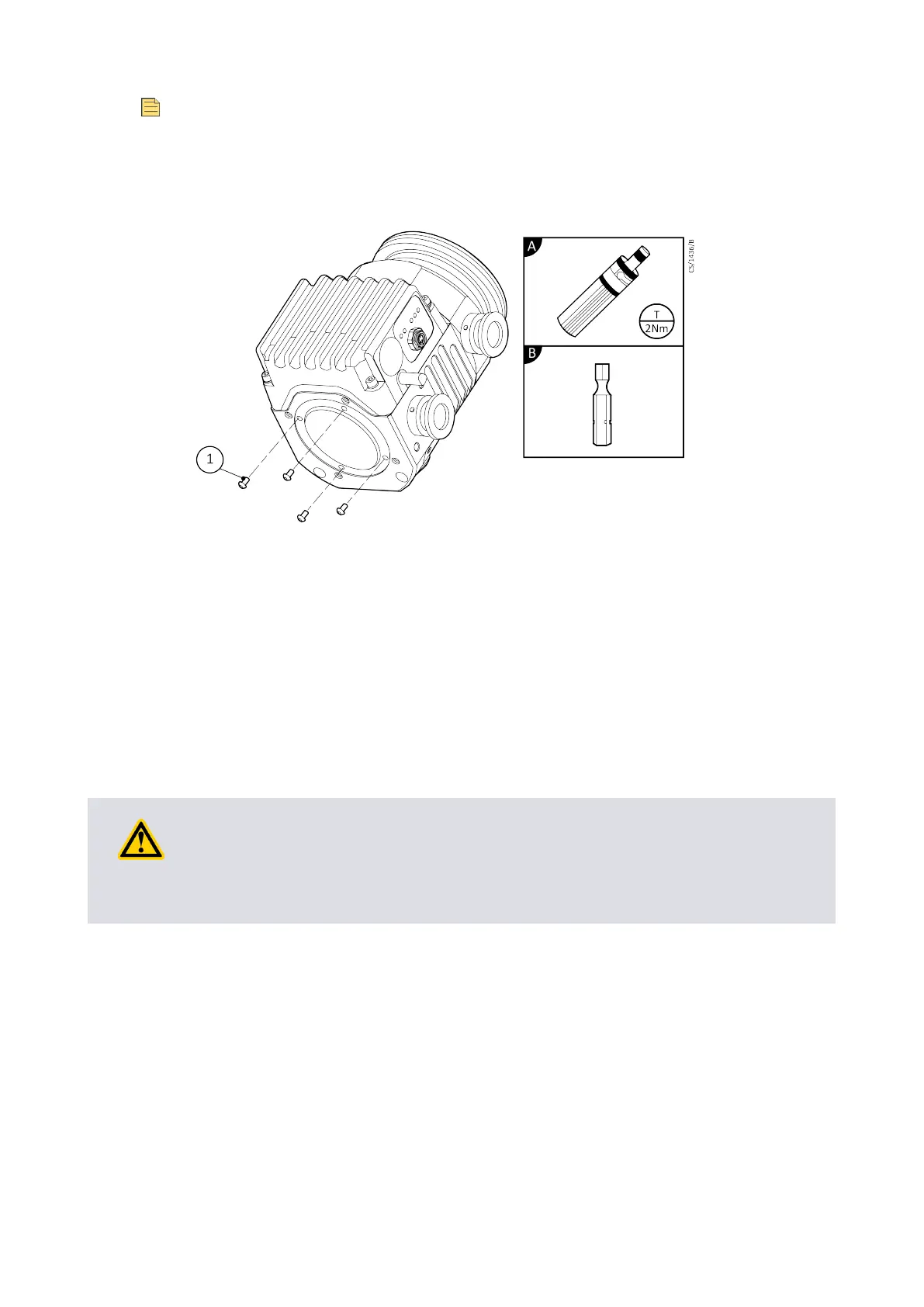

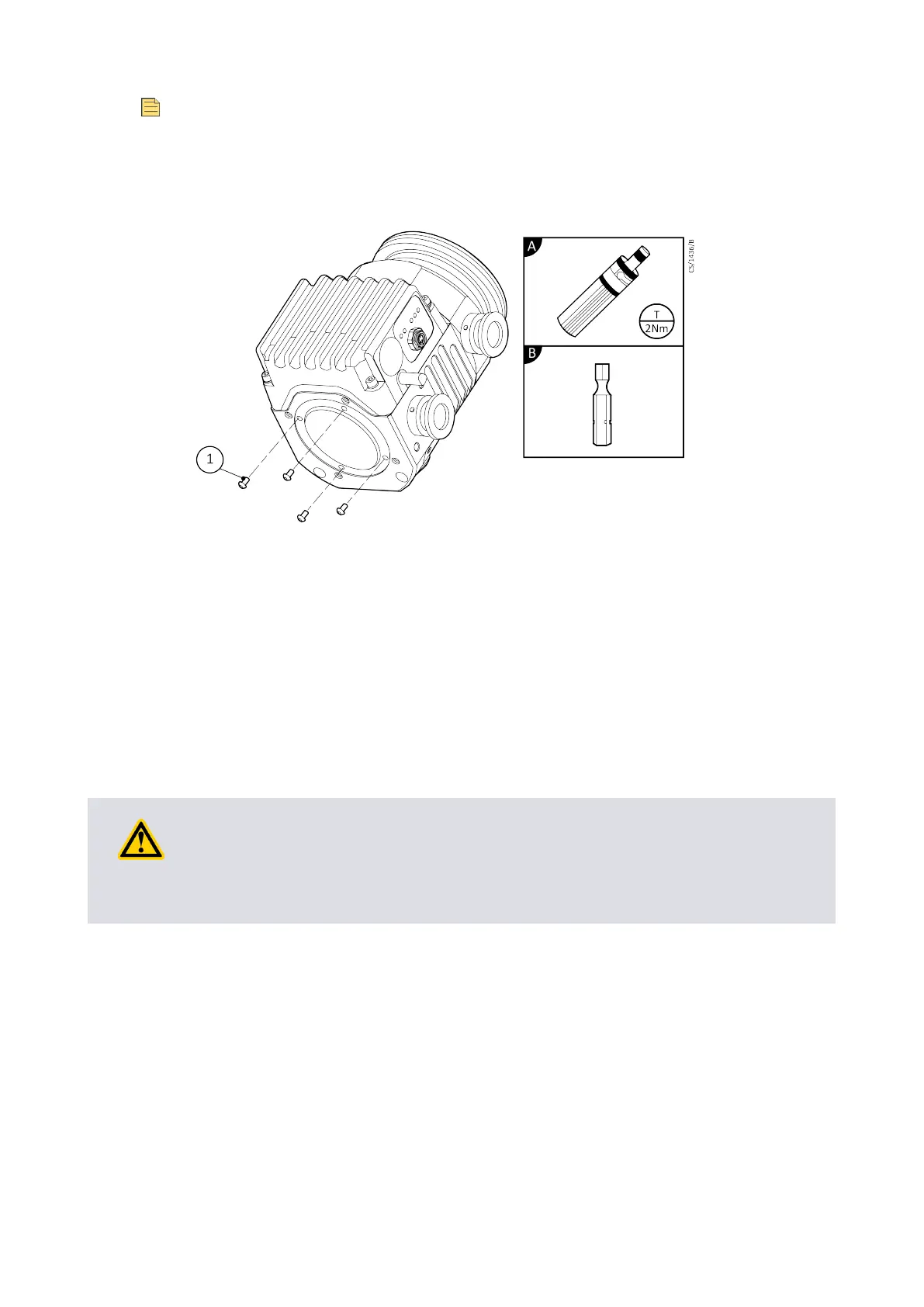

Figure 12

Oil cartridge assembly

1. 4 x M4 buon head screws

Tools

A. Torque driver

B. 4 mm hex bit

Bearing preload check

The bearing preload tool checks that the bearing preload force is correctly set. If necessary,

the tool can be used to correct the bearing preload force if adjustment is required.

CAUTION:

Bearing preload checking is required to check and if necessary set the bearing preload

using the bearing preload tool. Failure to do so may shorten the service life of the

pump.

1. Fit and use the preload tool in accordance with pre-service Preload check on page 9.

While performing this check, the posion of the test indicator must be noted when

a change in preload transion occurs. Refer to Figure 13 on page 18.

2. If the test indicator falls within the pass limit, then no further acon is required.

Proceed to Service counter reset on page 18.

3. Adjustment of the bearing preload force will be required if the test indicator falls

above or below the pass limit when a change in preload transion occurs. Using the

preload tool body, rotate the magnec bearing adjuster nut (viewed from top)

clockwise if the test indicator is above the pass limit and an-clockwise if the test

indicator is below the pass limit.

It is advisable to monitor the preload force using the preload tool test plunger

between 1 mm rotaonal increments. Connue this process unl the test indicator

B8G2-00-840A - Service

Page 17

Loading...

Loading...