6.3.2 Installing a D-sub Pin onto a TC or Tin Copper Wire:

D-sub pins are used in D-sub connectors found on the EDC and the MVP. Most of these pins have already

been installed on the appropriate wires and inserted into the proper connector. To install a D-sub pin requires

a D-sub crimp tool. Most electronic stores carry a reasonably priced D-sub crimp tool. This tool will work

for installing D-sub pins onto tin copper wire but it may not make good crimps on 24 gauge thermocouple

wire. A pull test can be performed to test the crimp. A ratcheting crimp tool from Tyco (P/N: 91503-1) will

crimp both TC and Tin Copper Wire. All crimps must pass a 3 to 4 pound pull test to be considered reliable.

To install a D-sub pin onto a 20 gauge Tin Copper Wire, perform the following steps:

A. Strip the insulation back 1/8.” Be careful not to knick the wire.

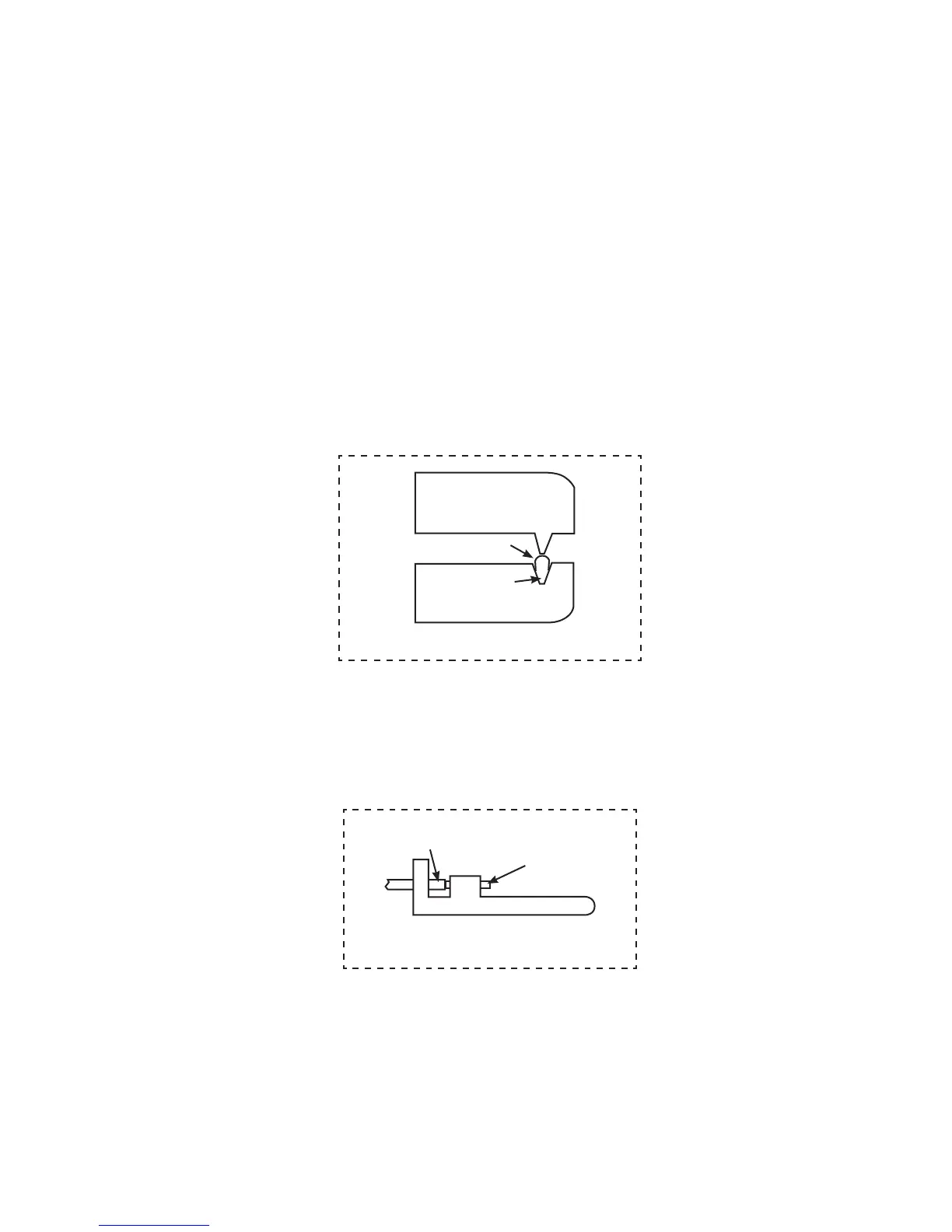

B. Insert the pin into the 24 gauge D-sub Pin Crimper. The crimpers have two cavities; the smaller

one is used to crimp the bare wire and the slightly larger one is used to crimp around the insulation.

Check that the pin is inserted into the crimpers properly. Note: the ears on the pin must be facing

into the center of the crimp tool cavity to produce a good crimp. If the pin rotates even a little

during crimping, the connection will be unreliable.

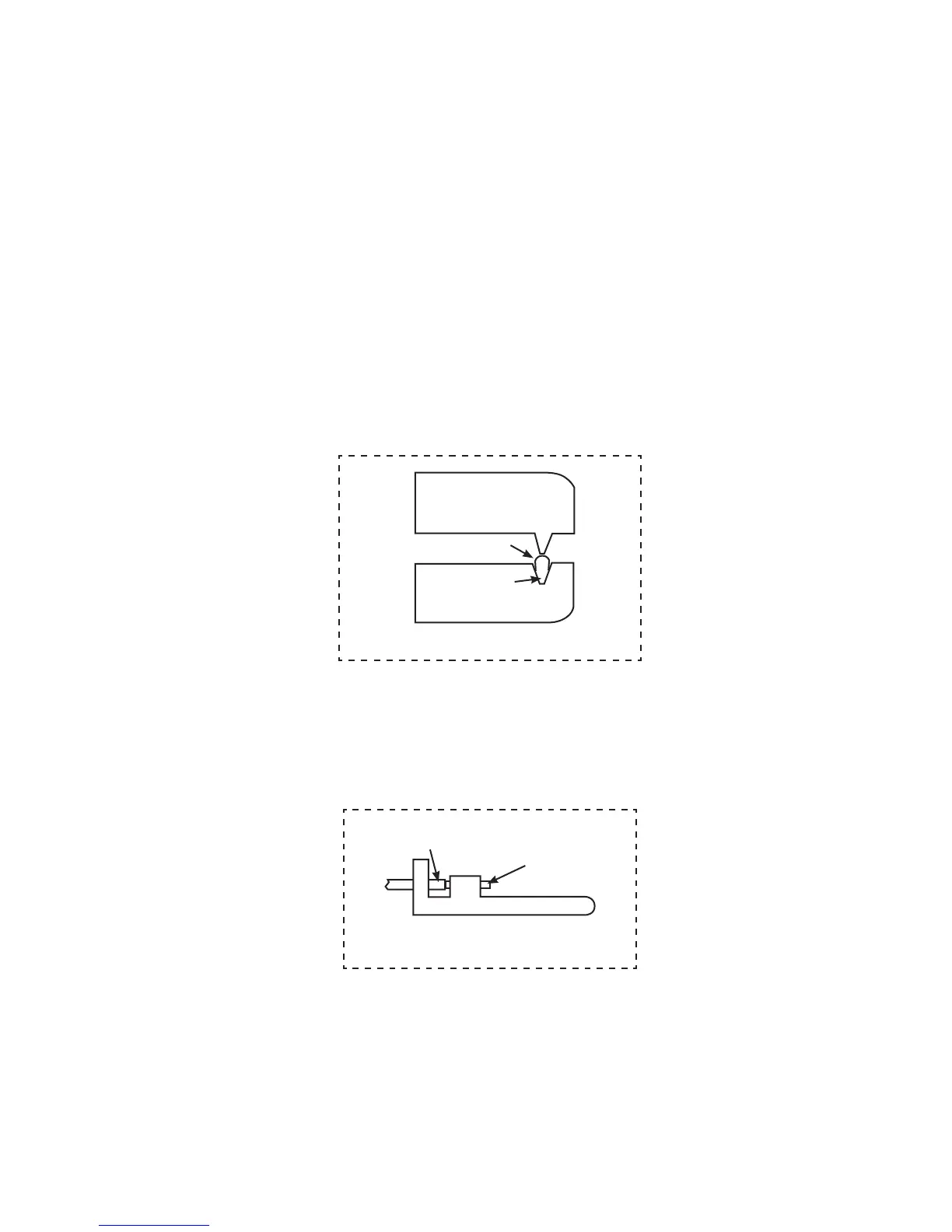

C. Insert the wire into the pin. Check that the insulation is in the strain relief crimp area but not in

the bare wire crimp area. Crimp the pin onto the wire. A good crimp is very important. Poor crimps

will cause jumpy readings and are the biggest source of problems.

End View

D-Sub Pin in the Crimp Tool

Crimp Cavity

Pin Ears face Down

EI D-Sub Pin

Insulation

Bare Wire

D. Pull Test: Pull (approximately 3 to 4 pounds) on the wire near the connector with one hand while

holding the connector with the other hand. If the wire pulls out of the connector, you must start over

using a new connector.

E. A well soldered connection at the crimp can be reliable. Soldering a TC wire requires a lot of heat

to produce a good solder connection. Also, when soldering a TC wire, each wire should be scraped

with a knife to expose fresh metal just before crimping and applying solder. Fluxing the TC will

allow the solder to ow better; however, DO NOT use acid core solder or acid ux.

44

Loading...

Loading...