Resistance Welder MULTISPOT MI-100

Operation

31

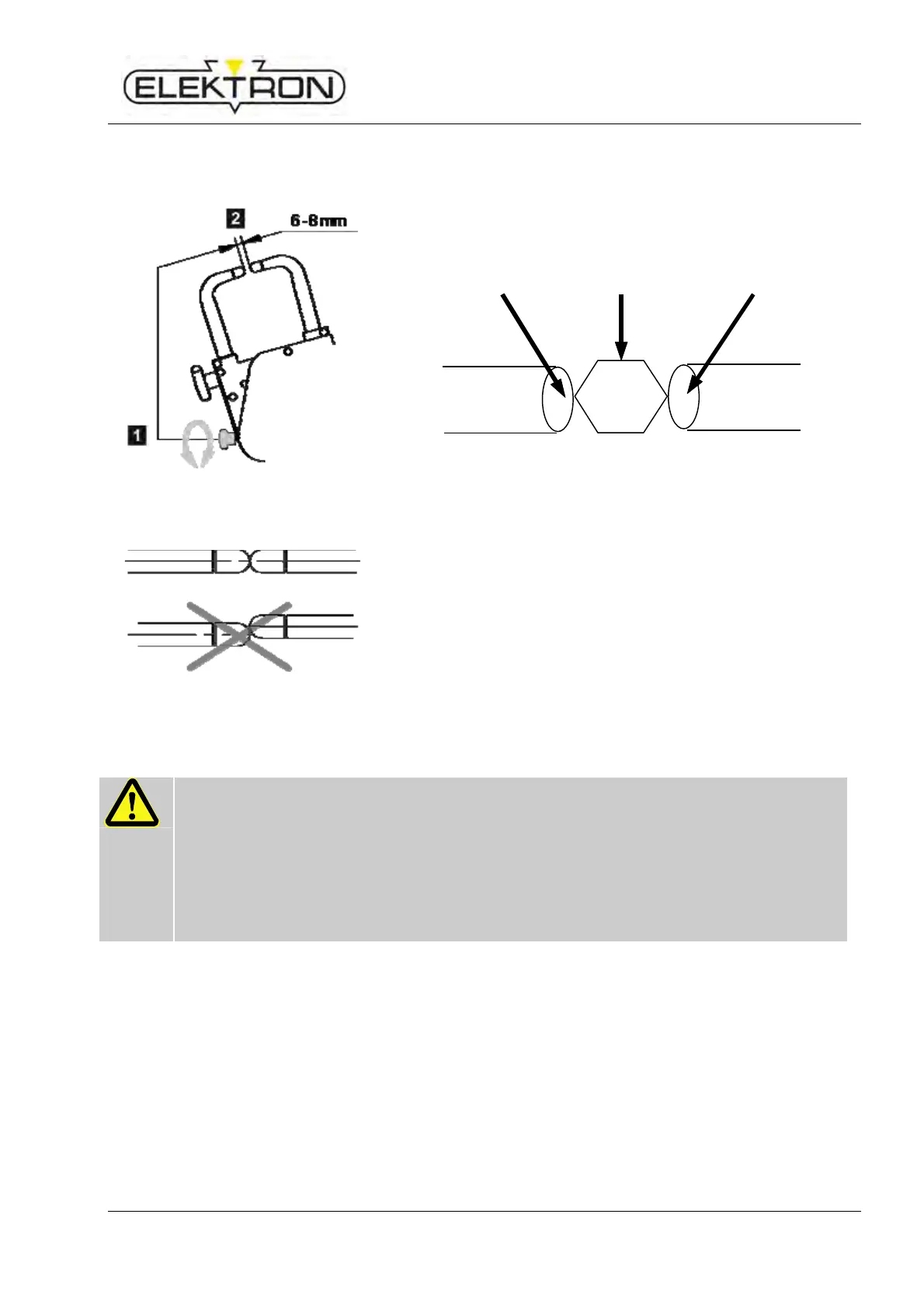

Adjusting the distance between

electrodes

Fig.35: Adjusting the distance between

electrodes

Make sure the distance between the electrodes is 6 to 8 mm.

Carry out the first welds, and then check the distance again.

Re-adjust, if necessary.

Use an Allen key SW5 as gauge in between the tips:

Electrode tip Allen key Electrode tip

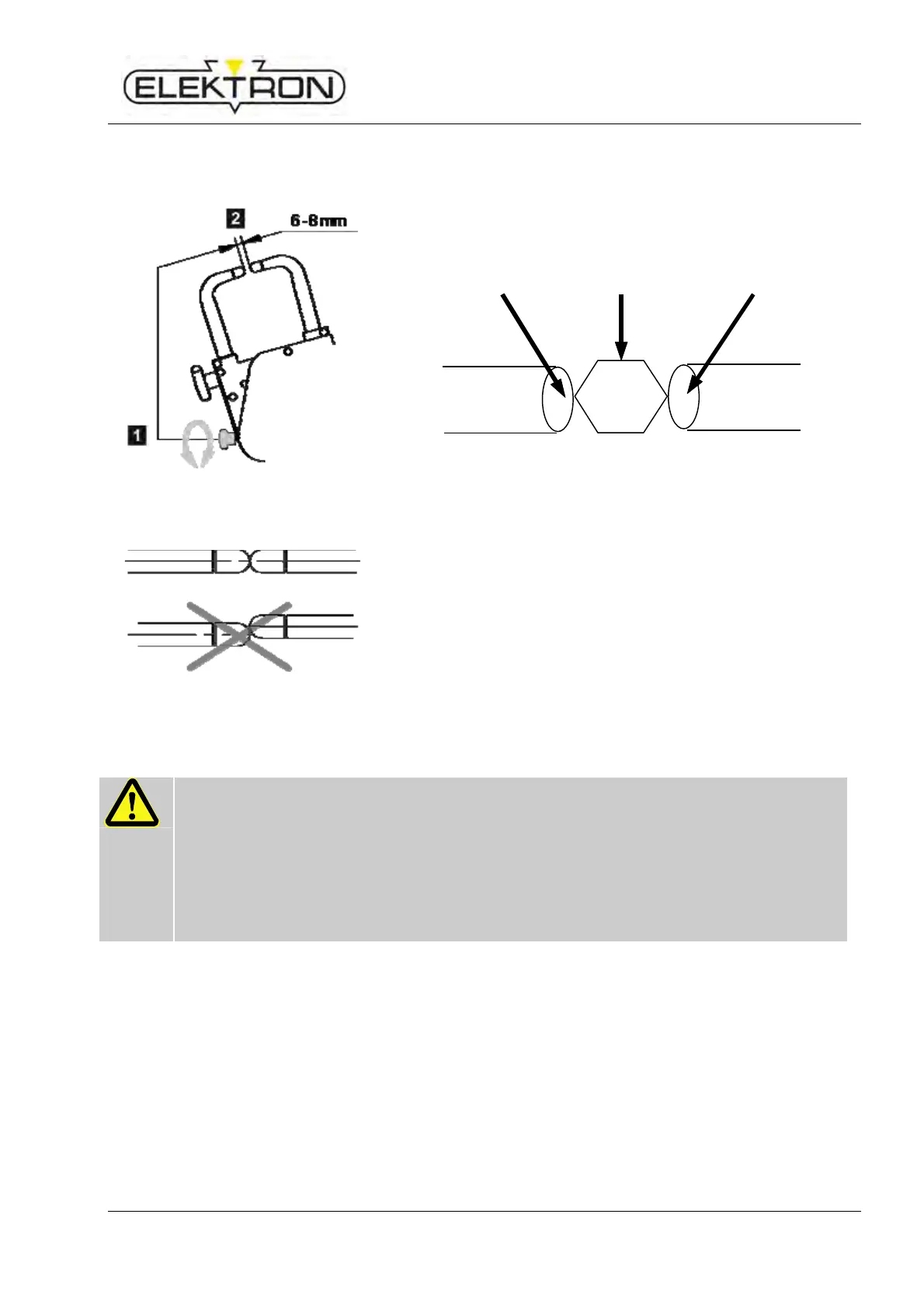

Aligning electrodes

Fig.36: “Electrode must be in true

alignment”

Be sure to look from different angles. Electrodes must align no

matter how you look.

6.1.3 Checks before switching on

WARNING ! Unskilled employees may hurt themselves and others. Inexpert operation

constitutes a hazard of injuries.

Inexpert and/or negligent handling of this equipment and/or ignorance of hazards and dangers

may entail the most severe injuries. Therefore:

Make sure this equipment is put to use by skilled welding operators with sufficient training

and experience in spot welding, exclusively.

Before operation, consult the manual and make sure any and all preconditions are fulfilled,

any and all checks and preliminary works etc. have been carried out.

Work place must be clean and tidy – no clutter. Make sure you have enough room to move.

Be sure to be wearing adequate PPE. ( See “2.2.3”.)

Check any and all connections. ( See “5”.)

Check input pressure. ( See “5.5”.)

Check cooling water level. ( See “5.2”.)

Check your tools / welding pliers). Re-tool now, if necessary.

( See “6.1.2” and/or separate operating instructions for welding pliers.)

Loading...

Loading...