Resistance Welder MULTISPOT MI-100

Maintenance

44

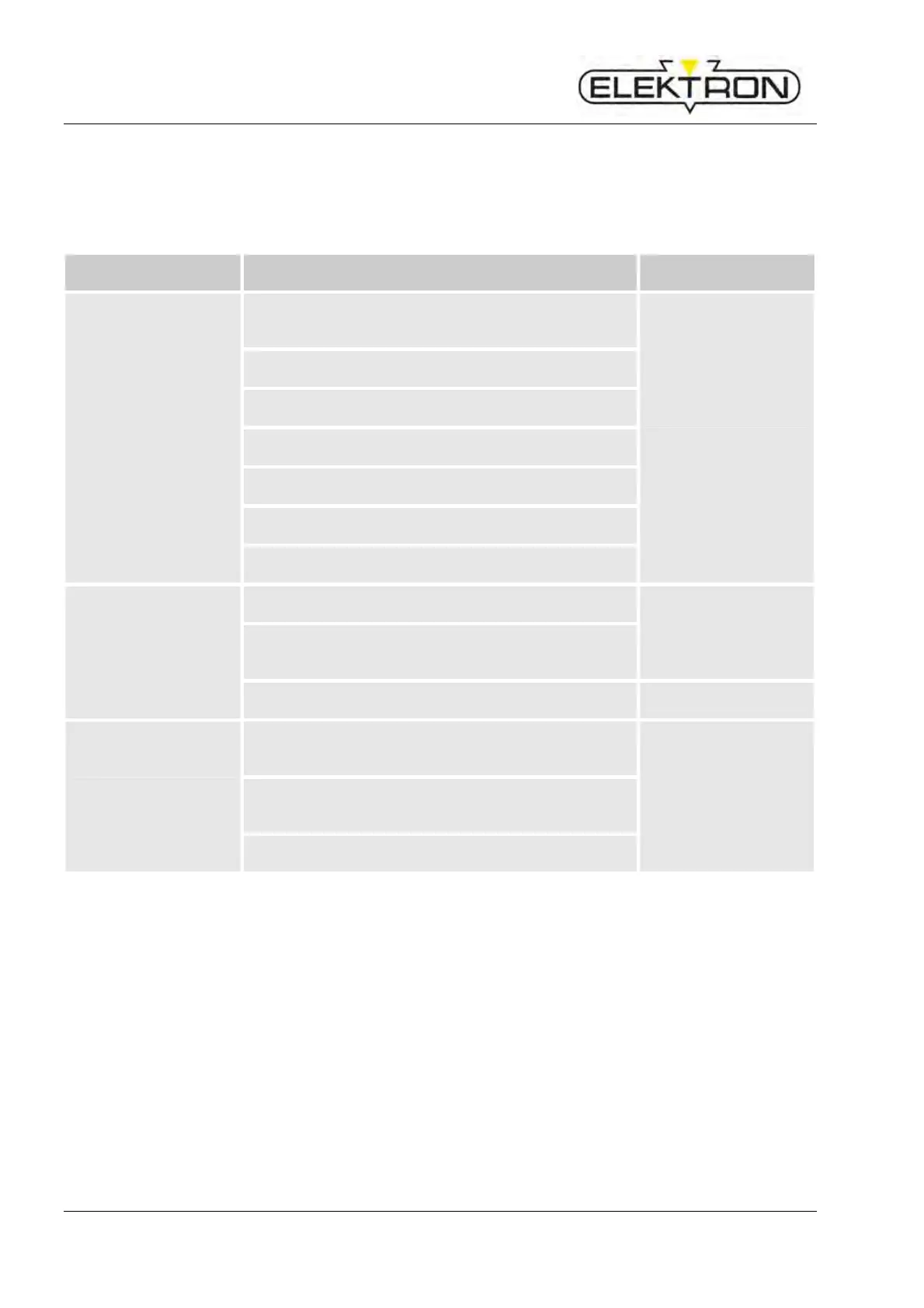

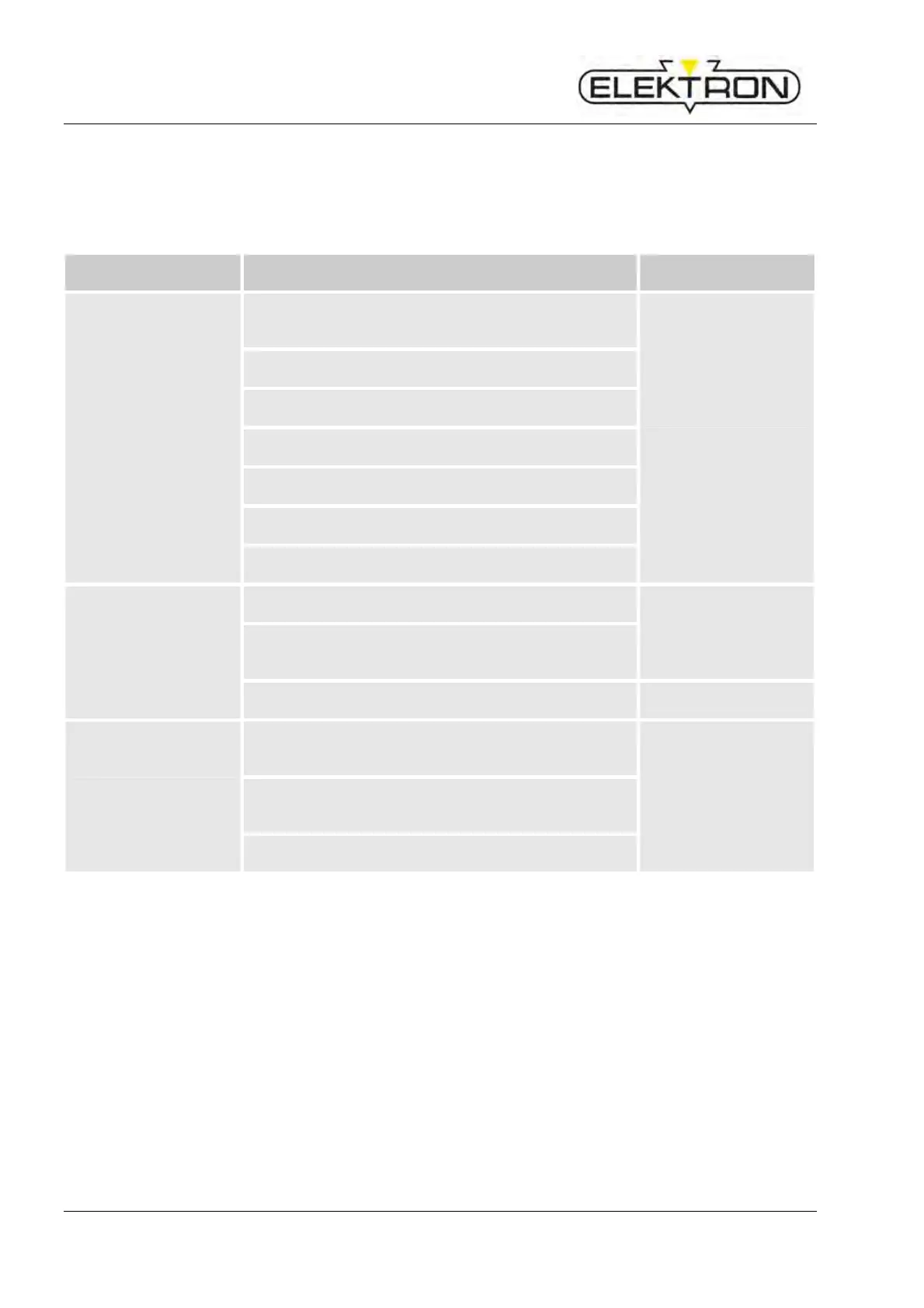

8 Maintenance

8.1 Maintenance schedule

Intervals What must be done? WHO should do

it?

Visually check the welder and its periphery for

damage, dirt, contamination etc.

Clean, if necessary ( see “8.2”).

Check connections for tight fit.

( See “5.4” – “5.6”).

Check compressed-air supply.

( see “5.5”

Check level gauge. Cooling water level okay?

Fill up, if necessary. ( See “5.2”.)

Visually check electrode caps. If necessary, clean,

mill and/or replace. ( See “6.1.2”.)

Check distance and –alignment of electrodes.

( See “6.1.2”.)

Before ANY

maintenance job

Check PPE for functionality. Replace, if and as

soon as necessary.

Operator

Check purity and quality of operating company’s

compressed-air supply.

Check the work environment. Does it still fulfil all

the operating requirements? ( See “9Fehler!

Verweisquelle konnte nicht gefunden werden.”.)

Operator

Every 6 months

Check actual input current and voltage. Take your

own measurements.

Skilled electrician

Visually check the water separator and air filter of

the pneumatic unit. Carry out jobs as required.

( See “8.2.2”.)

Visually check the water filter. Replace, if

necessary.

( See “8.2.3”.)

Whenever

necessary

Empty cooling water tank ( see “8.2.4”). Refill

( see “5.2”).

Operator

8.2 Carrying out maintenance jobs

Personnel

The maintenance jobs described here may be carried out by operators, if not explicitly stated

otherwise.

Have works on electrical equipment carried out by skilled electricians, exclusively.

Loading...

Loading...