73

English

•

Whenever possible, disassemble the hinge or pivot point.

•

Spray penetrating oil containing molybdenum disulphide onto the friction surfaces and allow the oil

to penetrate.

•

Wipe away all traces of old lubricant and dirt.

•

Should some parts not be accessible, use compressed air to remove all traces of old lubricant and

dirt from the joints and pivot points.

•

When pivot points are clean, apply new lubricant.

•

ELIET recommends Novatio Clear Lube as a lubricant for pivot points and rolling bearings. Novatio

PFT lubricant is more suitable for friction surfaces.

• Wipe away any excess lubricant.

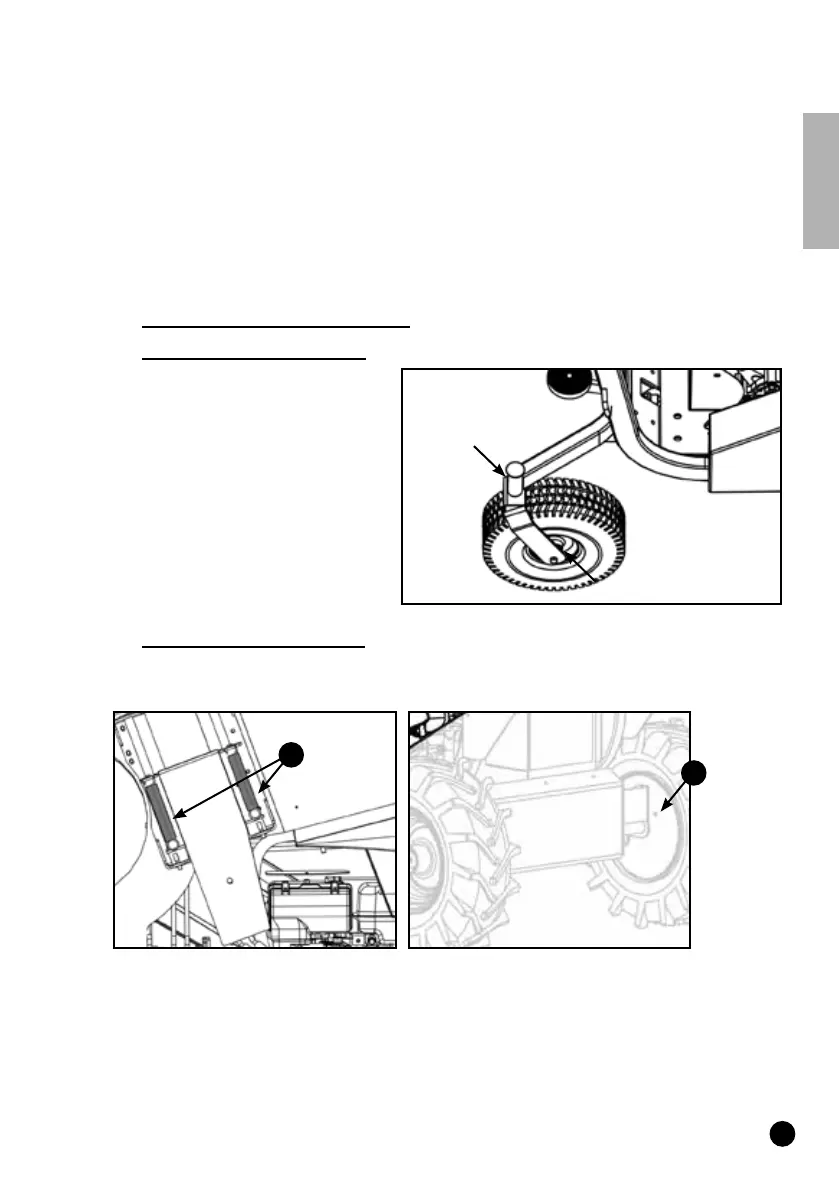

11.5.8.13. Lubricating using the grease fittings

11.5.8.13.1. Grease fittings for small doses

This group includes the following

locations on the machine:

• Grease fitting on the pivot point of

swivel wheels.

• Grease fittings on the bearings of

swivel wheels.

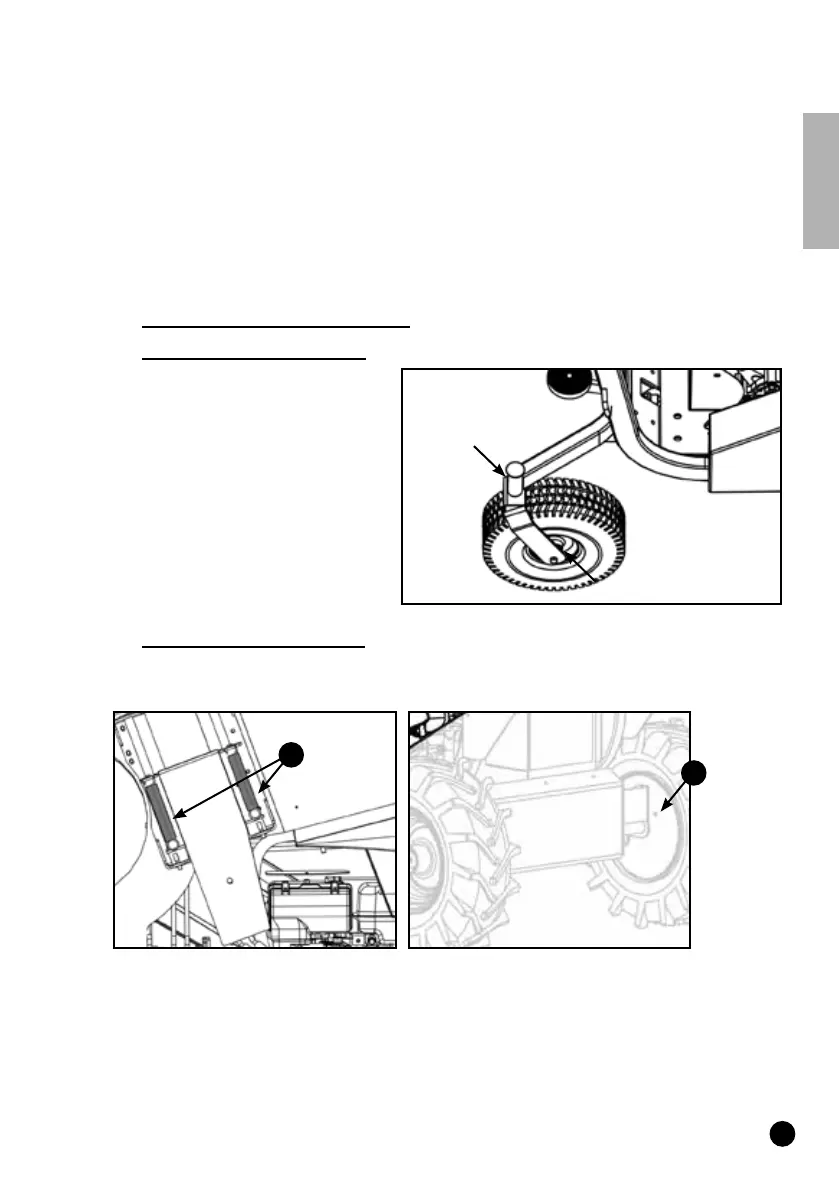

11.5.8.13.2. Grease fittings for large doses

• Grease fittings on the rods of the feeding roller (1)

• Transmission grease fittings in the rear rims (2)

Use the following procedure:

• Clean the grease fitting.

• Use a suitable grease pump to inject fresh grease into the grease fitting.

• ELIET recommends using MOBILGREASE XHP222.

• Pumping the grease gun one or two times is sufficient to inject enough grease.

• Wipe away any grease that comes out of the joints.

1

2

Loading...

Loading...