antiseize compound to the outer threads of the transducer holders before installing

them into the mounts.

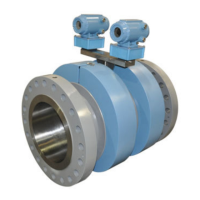

1.2.2 T-200 transducer assembly

Figure 1-2: T-200 transducer assembly

Procedure

1. Leave T-200 transducers installed on the 3410 Series Gas Ultrasonic Meter while the

line is pressurized.

2. Run the field hydrostatic test.

1.3 Routine maintenance

Routine maintenance operations requires adherence to all applicable regulations and laws

and safety training for personnel to perform the maintenance operations. Review your

organization’s best practices procedures before performing routine maintenance.

1.3.1

Maintenance logs and reports

To monitor the performance health of the meter, and ensure it is operating within

acceptable specifications, routine diagnostics should be performed. Collecting a

maintenance log gives you a snapshot of the current health of the meter and you can

compare the inspection reports from previously saved logs. Use the Logs/Reports menu

Maintenance Maintenance and Troubleshooting manual

June 2019 P/N 3-9000-769

14 Gas Ultrasonic Flow Meters

Loading...

Loading...