24. Twist and adjust wire removing all slack and seal. Remove excess wire (see Figure

3-23).

25. If required by the site operations manager, have an electrician fully test the

connections. After the Acceptance Test is witnessed and approved, seal the

conduit.

26. Power down the system and apply the sealing compound to the conduit and allow

to set in accordance with manufacturer specifications.

3.9 Replace the meter electronics

The following procedure should be performed by a qualified service technician or trained

personnel. Observe all warning labels on the meter before starting this procedure.

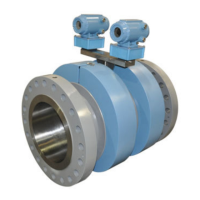

The Daniel 3410 Series Gas Ultrasonic Flow Meter Transmitter Electronics Enclosure

consists of the following:

• CPU Module assembly (P/N 1-360-03-010)

• Optional I/O Module (RS-232 or RS-485)

• I.S. Barrier Board (P/N 360-03-004)

• Power Supply (P/N 360-03-003)

• Backplane Board (P/N 360-03-007)

The Daniel 3410 Series Gas Ultrasonic Flow Meter Base Enclosure consists of the following:

• Acquisition Module (P/N 1-360-03-008)

• Acquisition Cable (P/N 360-01-595)

Should the Daniel 3410 Series Ultrasonic Gas Flow Meter require disassembly in the field

(i.e., check boards, change switch settings, or replace boards), to prevent electrostatic

damage to the electronic boards, always use a ground strap while handling the circuit

boards. If one is not available, make sure you are electrically discharged before touching

the boards by first touching a metal surface such as a ground lug on the meter or a table.

Maintenance and Troubleshooting manual Meter repairs

P/N 3-9000-769 June 2019

Maintenance and Troubleshooting manual 87

Loading...

Loading...