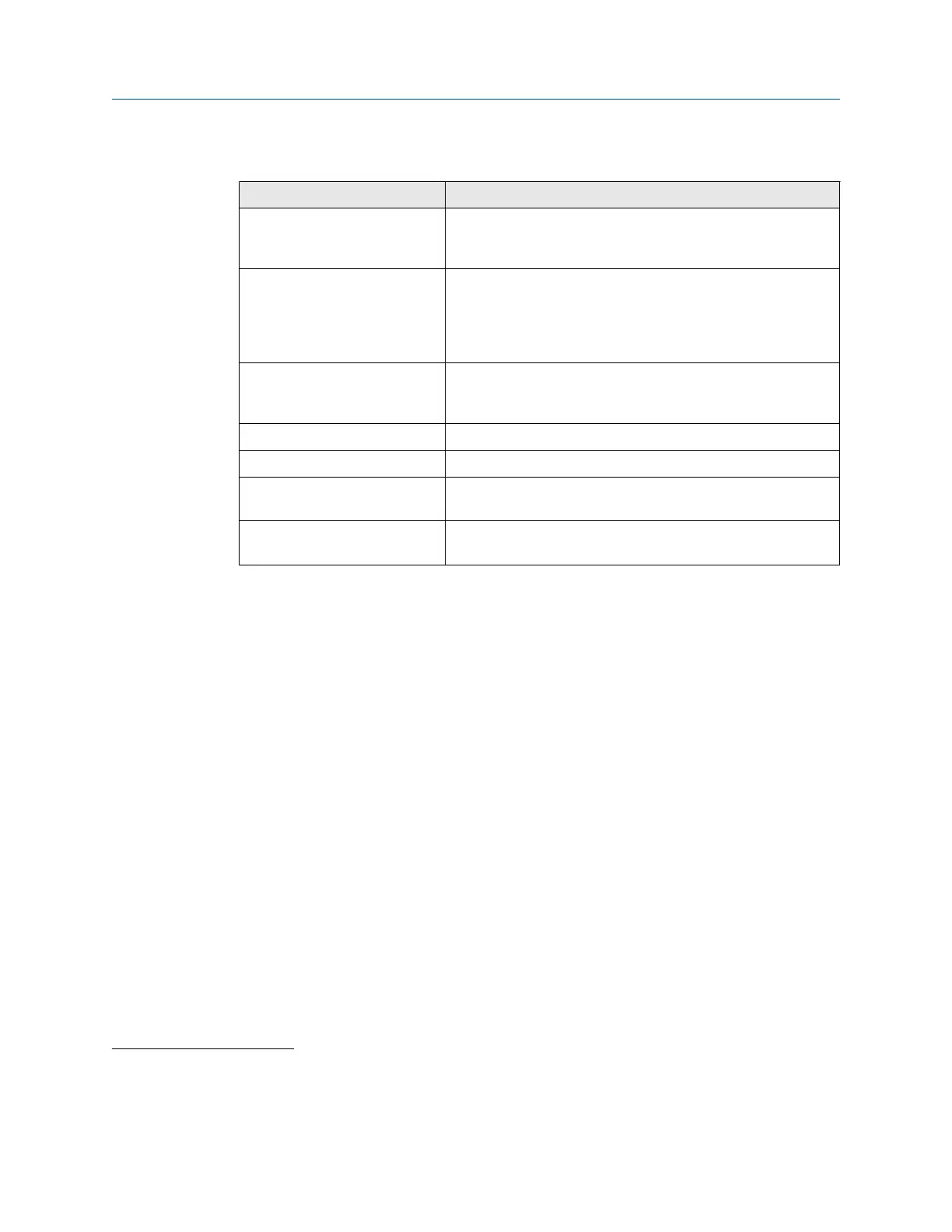

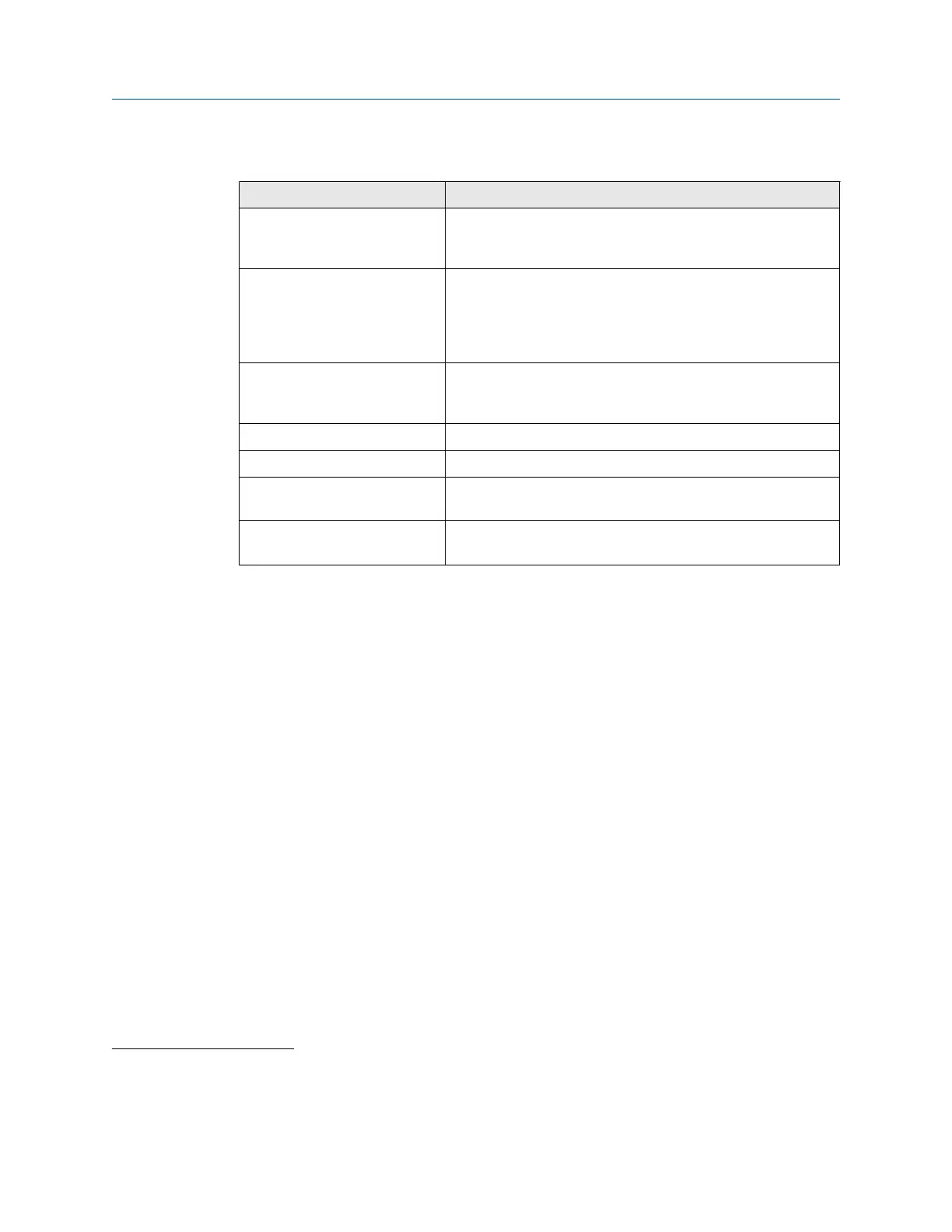

Table 2-2: Environmental conditions (continued)

Parameter type Description

Low and freezing temperatures Low specific gravities or high viscosities reduce the flow range of

the turbine meter. Refer to Operating parameters for the LTM

for more information.

Populated areas For new installations, locate the turbine meter to an area that

has fewer than 10 buildings intended for human occupancy,

within an area that extends 200 meters (220 yards) radially from

the turbine meter. (Reference: Class 1 location. U.S. DOT, CFR

Title 49: Part 192.5)

Closed, poorly ventilated areas

and combustion sources

Install the turbine meter in a well ventilated area, not less than

one meter (approximately 3 feet) from source of ignition or

source of heat which might damage the unit.

Elevation No limit.

Humidity No limit.

Proximity to open flame Provide fire prevention measures and equipment per local

regulations.

Proximity to vehicular traffic The design of the turbine meter has not been assessed for the

effects of traffic loads.

2.1.3 Operating parameters for the LTM

Turbulant flow is detrimental and affects turbine meter linearity

(1)

. It can cause non-

homogeneous fluid cross-section and inconsistant back pressure, possibly resulting in

cavitation

(2)

. To correct the flow characteristics, use upstream and downstream piping

lengths per Figure 2-3).

Pipe fittings such as elbows and tees, and piping components such as valves and strainers

should be located far enough upstream to dissipate any flow disturbance before it reaches

the turbine meter. The use of flow straighteners or a flow conditioning plate greatly

influences turbine meter performance.

Specific gravity

The turbine meter is affected by specific gravity which may influence performance. The

effect of specific gravity on the turbine meter may be evidenced when it is below 0.7. As

specific gravity decreases, the lift forces on the turbine blade decreases. Likewise as

velocity decreases, lift forces decrease. These reduced lift forces are overtaken by bearing

friction as low rates are approached. Subsequently, linearity deteriorates at low flow rates

while measuring light fluids.

(1) Linearity is the total range of deviation of accuracy, expressed as a curve, between minimum and maximum flow rates.

The ideal accuracy curve of a volumetric meter, such as the turbine, is a straight line denoting a constant meter factor.

(2) Cavitation is the formation and collapse of vapor-filled cavities that result from a sudden decrease and increase in

pressure. Refer to Back pressure calculation for more information.

User manual Operating conditions and specifications

P/N 3-9008-515 March 2019

User manual 43

Loading...

Loading...