These parameters uniquely identify the API table. The selected API table is displayed,

and the meter automatically changes the density unit, temperature unit, pressure

unit, and reference pressure to match the API table.

Restriction

Not all combinations are supported by the API referral application. See the list of API tables in

this manual.

3. Refer to the API documentation and confirm your table selection.

a. Verify that your process fluid falls within range for line density, line temperature,

and line pressure.

If your process fluid goes outside any of these limits, the meter will post a status

alert and will report line density instead of referred density until the process fluid

goes back within range.

b. Verify that the referred density range of the selected table is adequate for your

application.

4. If you chose a C table, enter Thermal Expansion Coefficient (TEC) for your process fluid.

5. Set Reference Temperature to the temperature to which density will be corrected in

referred density calculations. If you choose Other, select the temperature

measurement unit and enter the reference temperature.

6. Set Reference Pressure to the pressure to which density will be corrected in referred

density calculations.

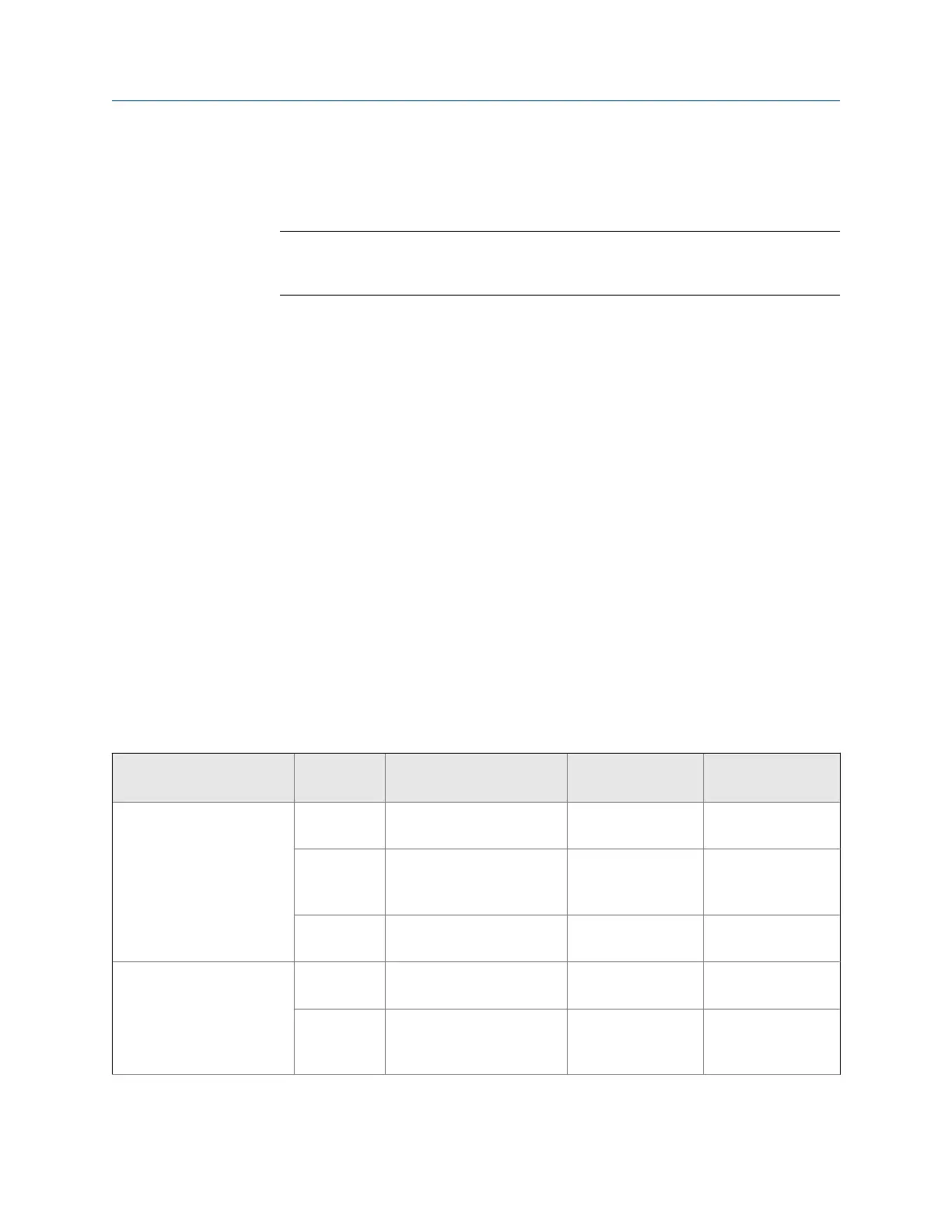

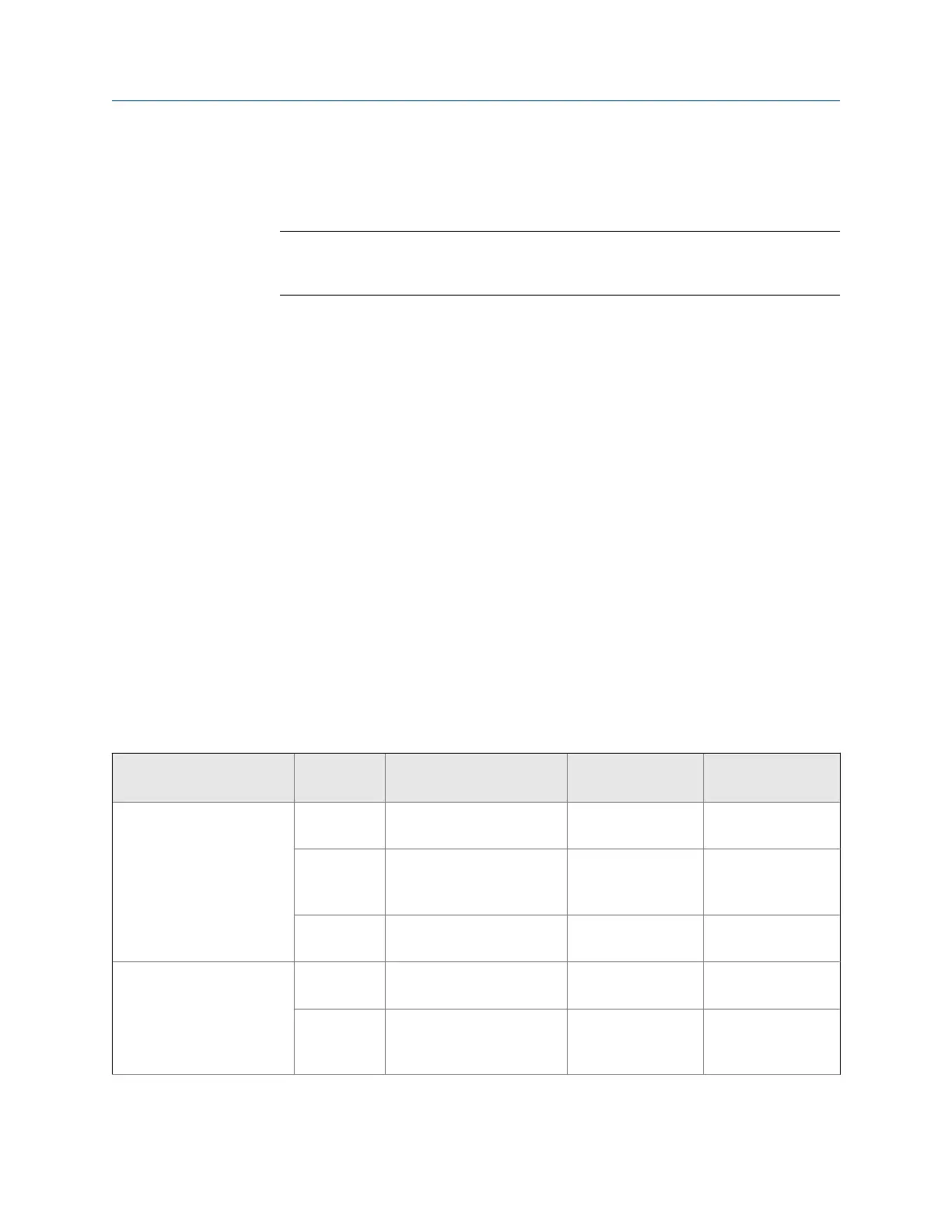

API tables supported by the API referral application

The API tables listed here are supported by the API referral application.

API tables, process fluids, measurement units, and default reference valuesTable 4-4:

Process fluid API table Referred density (API)

Default reference

temperature

Default reference

pressure

Generalized crude and JP4 5A Unit: °API

Range: 0 to 100 °API

60 °F 0 psi (g)

23A Unit: SGU

Range: 0.6110 to 1.0760

SGU

60 °F 0 psi (g)

53A Unit: kg/m

3

Range: 610 to 1075 kg/m³

15 °C 0 kPa (g)

Generalized products (gaso-

line, jet fuel, aviation fuel,

kerosene, heating oils, fuel

oils, diesel, gas oil)

5B Unit: °API

Range: 0 to 85 °API

60 °F 0 psi (g)

23B Unit: SGU

Range: 0.6535 to 1.0760

SGU

60 °F 0 psi (g)

Configure process measurement

36 Micro Motion

®

Fork Density Meters (FDM)

Loading...

Loading...