Emerson Process Management GmbH & Co. OHG 1-11

X-STREAM Non-Incendive

Instruction Manual

HASXENE-IM-EX

12/2014

1

Technical Description

1.6 Measurements Specifi cations

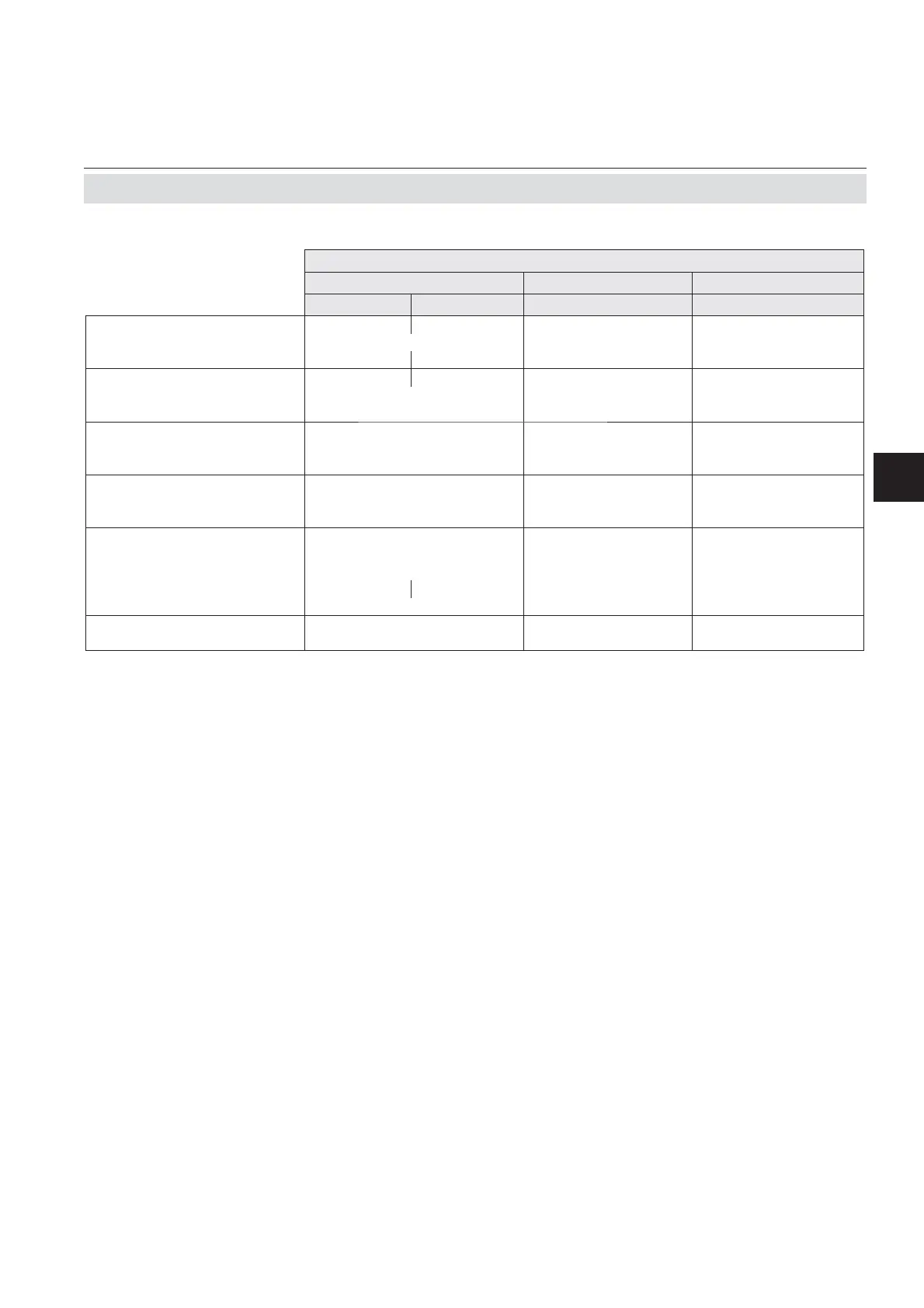

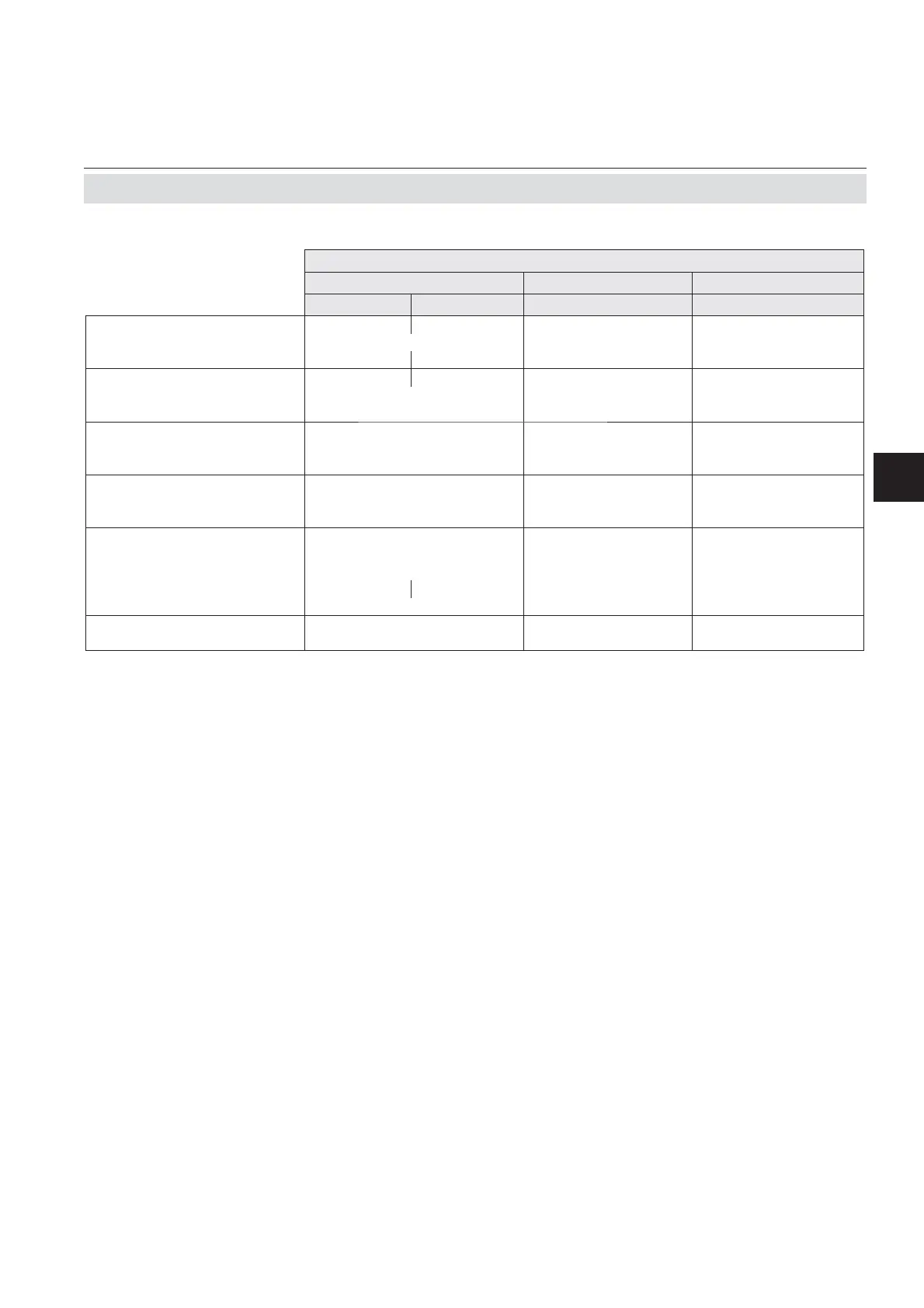

Tab. 1-4: Oxygen - Standard and Enhanced Measurement Performance Specifi cations

Note 1!

Not all data listed are applicable to all analyzer versions (e.g. 60 °C thermostatically controlled

box is not available for electrochemical and trace oxygen).

Note 2!

For NDIR/UV/VIS measurements, take into account that

• sample gas may diffuse or be released by leakages into the analyzer enclosure

• if existent in the analyzer surroundings, the component to be measured may enter the enclosure.

Concentrations then may increase inside the enclosure. High concentrations of the component

to be measured inside the enclosure may infl uence the measurement by unintended absorption,

which could cause drift of the measurement.

A remedy for this issue is to purge the housing with gas not containing the component of interest.

1

Related to full scale

2

Related to measuring value

3

From gas analyzer inlet at gas fl ow of 1.0 l/min

(electronic damping = 0 s)

4

Constant pressure and temperature

5

Range 0–10…200 ppm: ≤ 5 % (5 to 45 °C /

41 to 113 °F)

6

Pressure sensor is required

7

reserved for future use

8

Limited to atmospheric if internal sample pump

9

Temperatures below 0 °C (-4 °F) with thermostat

control only

10

Thermost. controlled sensor: 35 °C (95 °F)

11

For ranges 0–5…100 % and fl ow 0.5…1.5 l/min

12

Optional thermostatically controlled sensor with

temperature 60 °C (140 °F)

13

Temperature variation: ≤

10 K per hour

14

No sudden pressure surge allowed

Note! Take care of the tO

2

sensor‘s documentation, providing important calibration instructions!

Oxygen Sensors

Paramagnetic (pO

2

) Electrochemical (eO

2

) Trace (tO

2

)

Standard Spec Enhanced Spec

Detection limit (4 σ)

1 4

≤ 1 % ≤ 0.5 % ≤ 1 % ≤ 1 %

Linearity

1 4

≤ 1 % ≤ 1 % ≤ 1 %

Zero-point drift

1 4

≤ 2 % per week ≤ 1 % per week ≤ 2 % per week ≤ 1 % per week

Span (sensitivity) drift

1 4

≤ 1 % per week ≤ 0.5 % per week ≤ 1 % per week ≤ 1 % per week

Repeatability

1 4

≤ 0.5 % ≤ 1 % ≤ 1 %

Response time (t

90

)

3

< 5 s approx. 12 s 20 to 80 s

Permissible gas fl ow 0.2–1.5 l/min 0.2–1.5 l/min. 0.2–1.5 l/min.

Infl uence of gas fl ow

1

4

≤ 2 %

11

≤ 2 % ≤ 2 %

Maximum gas pressure

8

≤ 1500 hPa abs. (≤ 7 psig)

14

≤ 1500 hPa abs. (≤ 7 psig) ≤ 1500 hPa abs. (≤ 7 psig)

Infl uence of pressure

2

– At constant temperature ≤ 0.10 % per hPa ≤ 0.10 % per hPa ≤ 0.10 % per hPa

– With pressure compensation

6

≤ 0.01 % per hPa ≤ 0.01 % per hPa ≤ 0.01 % per hPa

Permissible ambient temperature

9

0(-20) to +50 °C (32 (4) to 122 °F) 5 to +45 °C (41 to 113 °F) 5 to +45 °C (41 to 113 °F)

Infl uence of temperature

1 13

(at constant pressure)

– On zero point ≤ 1 % per 10 K ≤ 0.5 % per 10 K ≤ 1 % per 10 K ≤ 1 % per 10 K

5

– On span (sensitivity) ≤ 1 % per 10 K ≤ 1 % per 10 K ≤ 1 % per 10 K

5

Thermostat control 60 °C (140 °F)

12

none none

10

Warm-up time Approx. 50 minutes - Approx. 50 minutes

Note! 1 psi = 68.95 hPa

Loading...

Loading...