Electrical

© 2013 EMP, Inc 16

Wiring

Wire Sizing

- For complete connector body sealing the

ignition wire should be 16ga minimum and

the power and ground wires should be 12ga

minimum

Recommended Wiring Practices

- Wiring or electrical harness must not rub on

sharp edges.

- The electrical harness should not be

stressed at connections (see Figure below)

-

- The voltage drop between the battery and

the fan should not exceed 5% of the rated

battery voltage. This should be verified at

the pump’s maximum current draw.

Wiring or electrical harness must not rub or

make contact with a hot surface. There

should be 5" minimum clearance from the

exhaust.

- Wiring or electrical harness should be

supported at least every 18" to 20".

- To avoid possible fire or shock, do not pinch

any wiring or electrical harnesses.

-

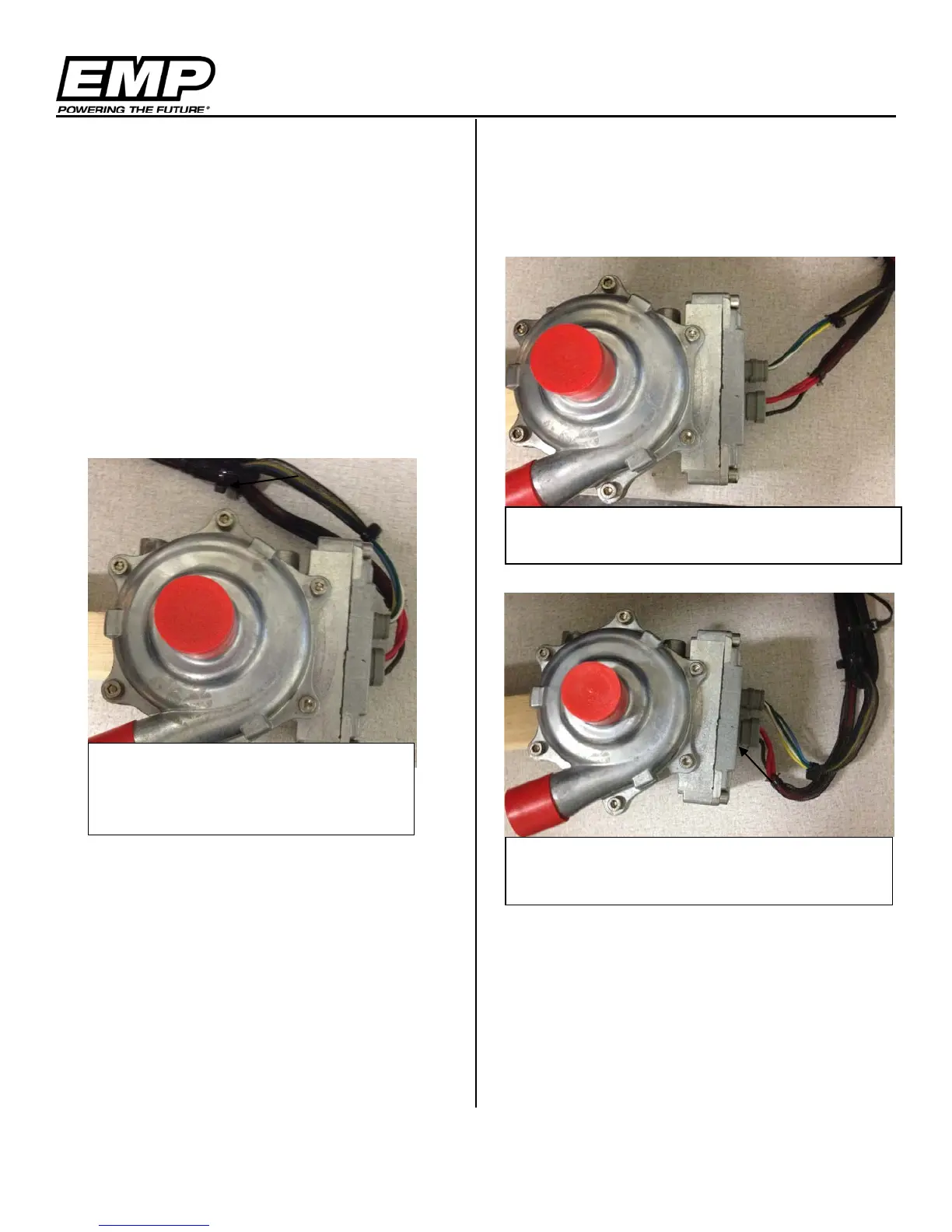

- Incorporate Drip Loops into wiring designs

(see Figure below). The pump connectors

are environmentally sealed. However, good

wire management can help ensure a good

seal over the life of the product

- The use of Dielectric Grease such as Dow

Corning DC-4 is acceptable as long as the

connection is mated directly after grease

application to prevent dirt from being

captured by the grease

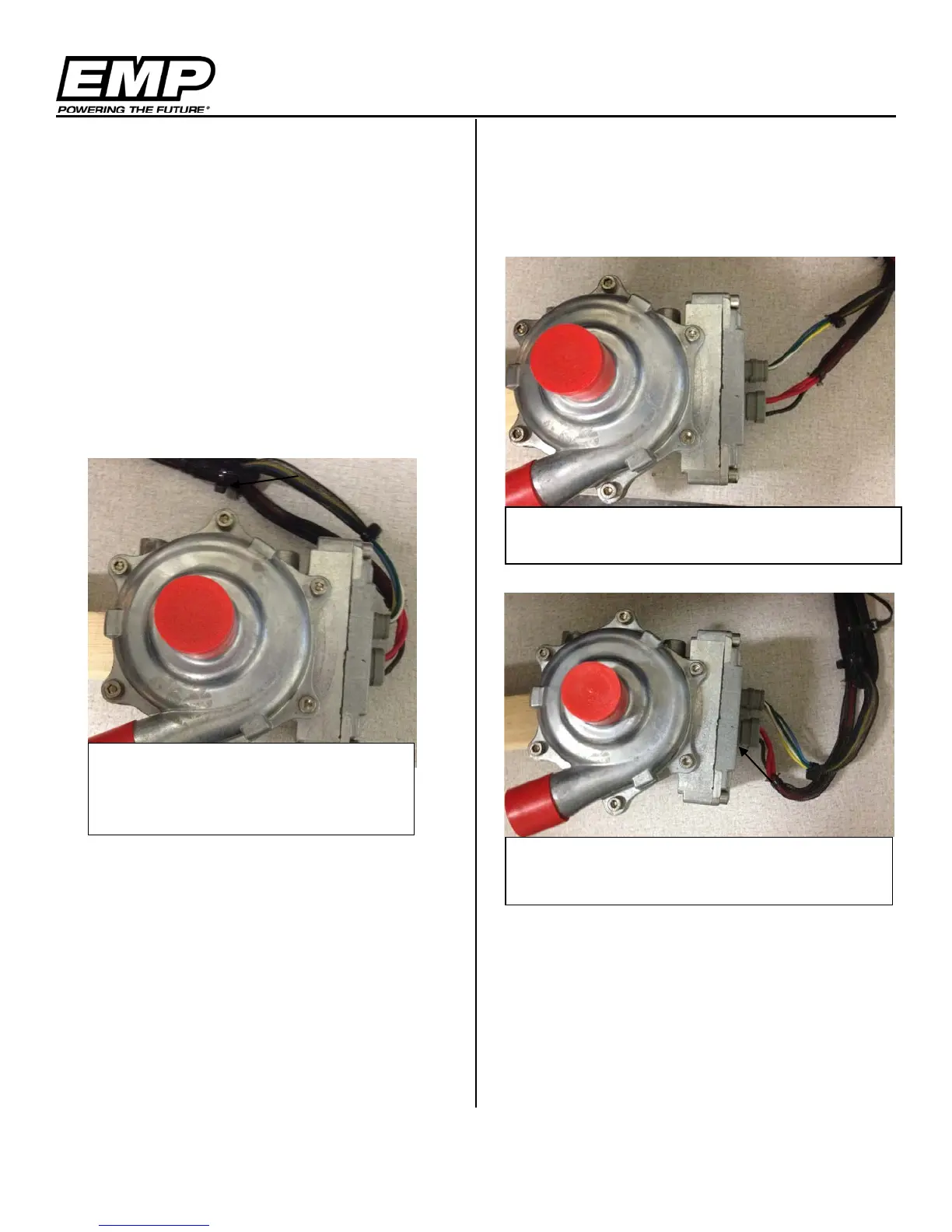

Wires pulling on connectors can

compromise the connector body seal

and possibly create a water intrusion

Wire routing provides a path for water to flow

down into connector

Drip loop collects water and sheds it away

from connectors

Loading...

Loading...