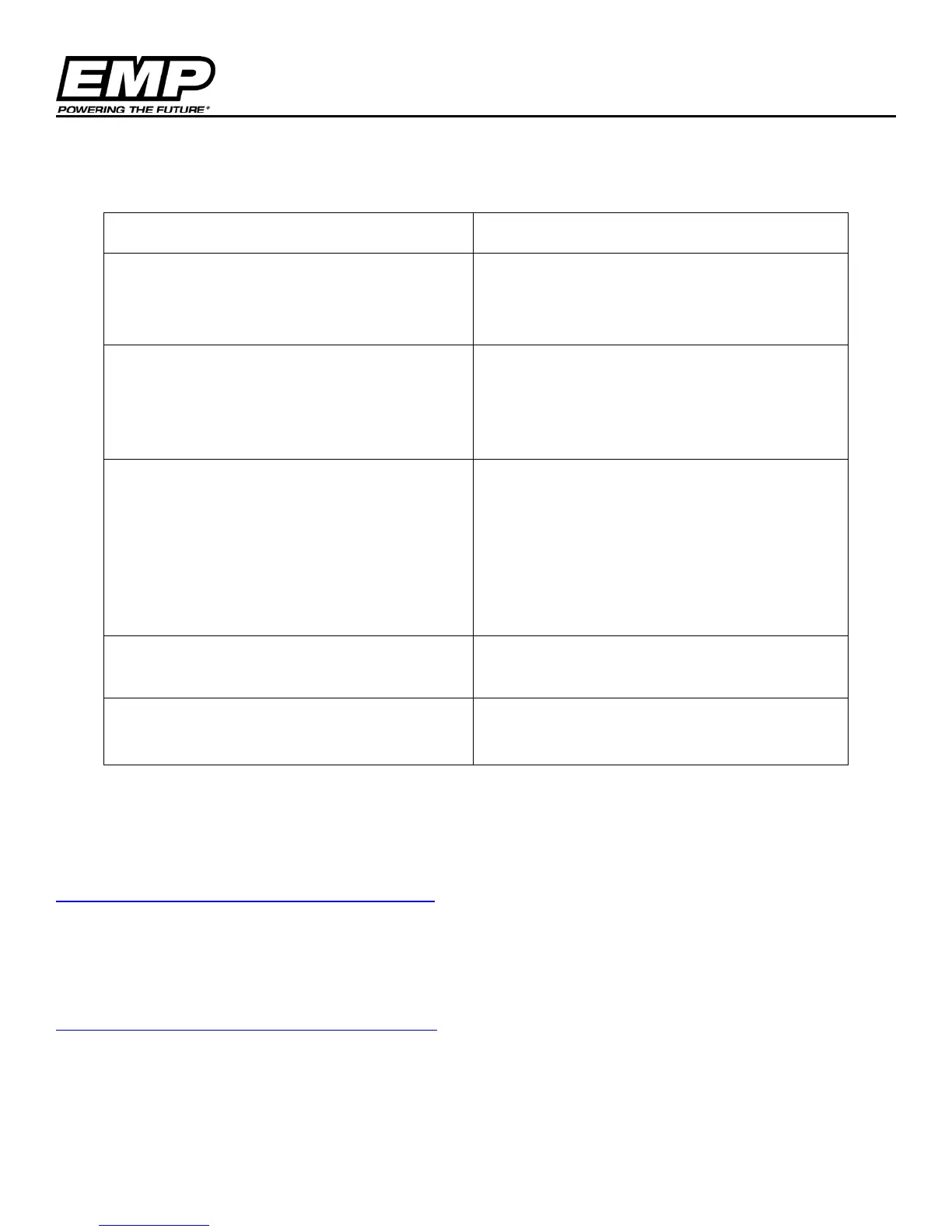

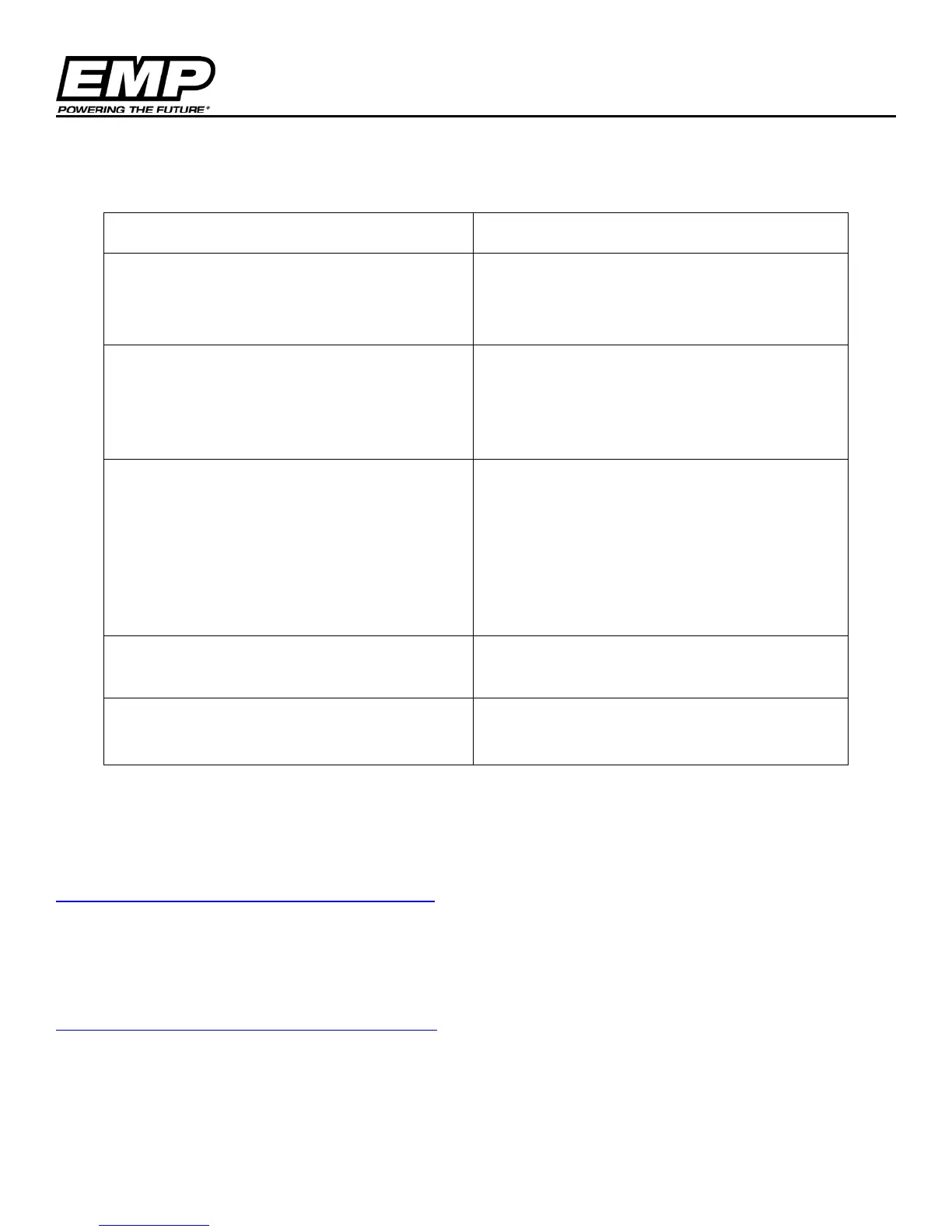

Troubleshooting

© 2013 EMP, Inc 20

Troubleshooting

Symptom Check

Pump not running.

• Check electrical connections

• Check ignition wire

• Check if ignition wire is “on”

•

Pump is running but not pumping fluid.

• Check system fluid level

• Check for tubing restrictions (kinks)

• Make sure pump is primed

• Check for collapsed inlet or outlet hose

•

Check pump inlet for trapped debris

No CAN communication and/or pump not

responding to CAN commands

• Check communication harness wiring.

• Verify that CAN messages are being

transmitted in the proper formats (see

online Technical Guide or contact EMP

Technical Support for CAN message

details).

• Verify that the proper component CAN

P

ump bearings are making a grinding noise

when running

Pump is leaking excessively while running

• Replace pump. No action is required by

customers for pumps exhibiting acceptable

EMPower Connect™ Service Tool

Monitoring operation and manual control of the pump can be accomplished using the service tool

EMPower Connect which is part of the EMP Service Suite available at no cost on our website at:

http://www.emp-corp.com/support/downloads/ . To use EMPower Connect download and install on

your PC. If the pump is being run standalone you will also need an interface cable from the 6 pin

Deutsch connector on the pump and an EMP USB/TTL converter. Both are available as a kit P/N

7500038001. If the pump is on a J1939 CAN bus EMPower Connect™ can be run using a Data Link

Adapter (DLA) to interface to the CAN bus.

A user guide for EMPower Connect™ can be found here:

http://www.emp-corp.com/support/documents/

Loading...

Loading...