16

F

i

r

s

t

c

l

o

s

e

t

h

e

c

a

p

w

el

l

.

T

h

e

n

s

t

a

r

t

t

h

e

u

n

i

t

F

i

r

s

t

c

l

o

s

e

t

h

e

c

a

p

w

el

l

.

T

h

e

n

s

t

a

r

t

t

h

e

u

n

i

t

Max 40g

WOLF-RIA

R

2S

Water

Water

Power

Airflow

Verwijder het poeder van de schroefdraad voor-

dat u het deksel er op draait.

Controleer of het deksel niet beschadigd

is. Vervang beschadigde onderdelen direct.

Controleer of het poederreservoir stevig

dichtgeschroefd is. Er zou anders lucht en / of

poeder kunnen uitlekken.

Controleer de o-ring van het deksel. Raad-

pleeg de informatie in het hoofdstuk "Normale

reiniging en Onderhoud".

Čistitenavojespremnikazaprahprijenego

pritegnete vijak kapice.

Provjeritedakapicanijeoštećena.Odmah

zamijeniteoštećenedijelove.

Provjeritedajespremnikzaprahčvrstoza-

tvoren. U suprotnom zrak i/ili prah mogu istjecati

kroz otvor.

Provjerite o-prsten kapice. Slijedite upute

naznačeneupoglavlju“Redovitočišćenjei

održavanje”.

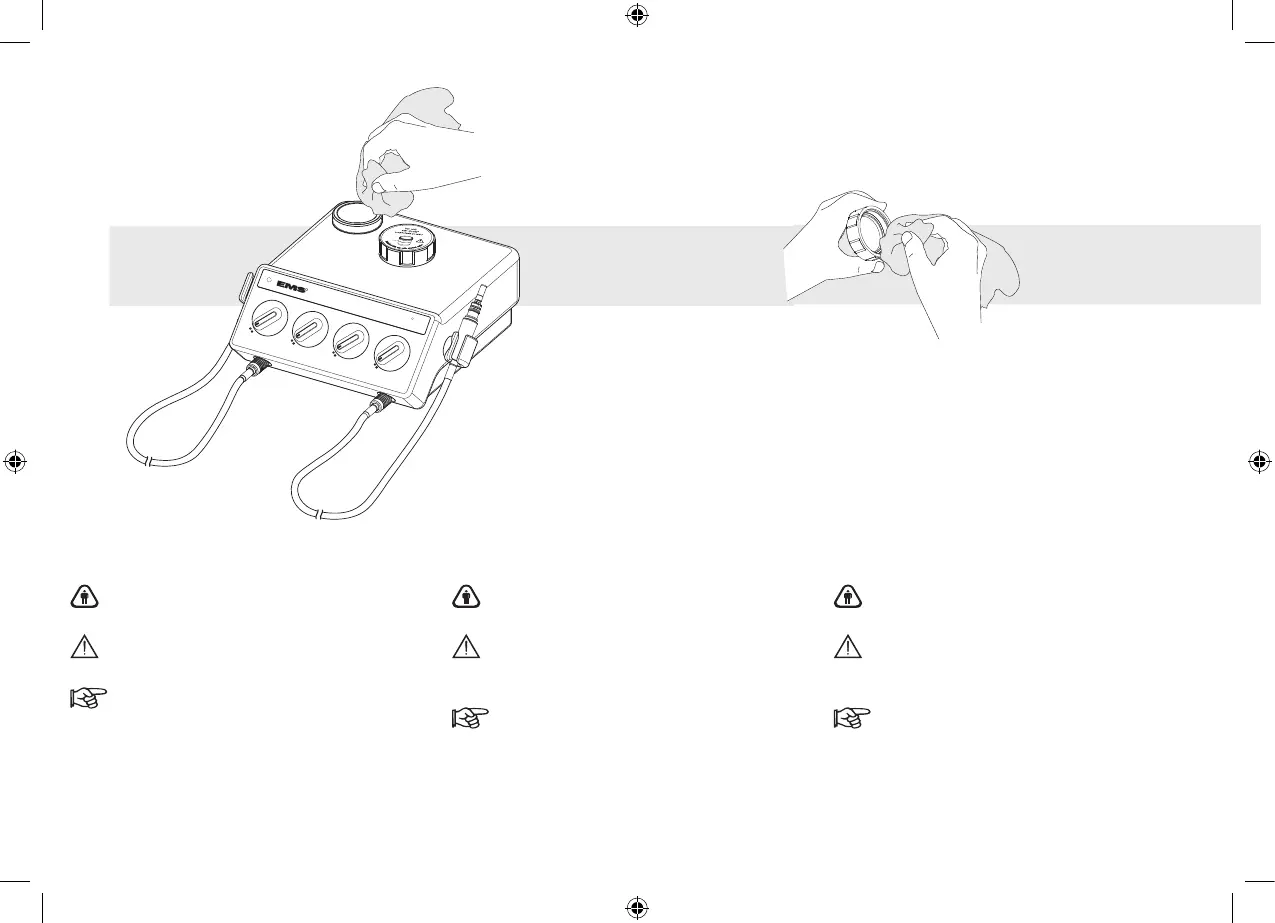

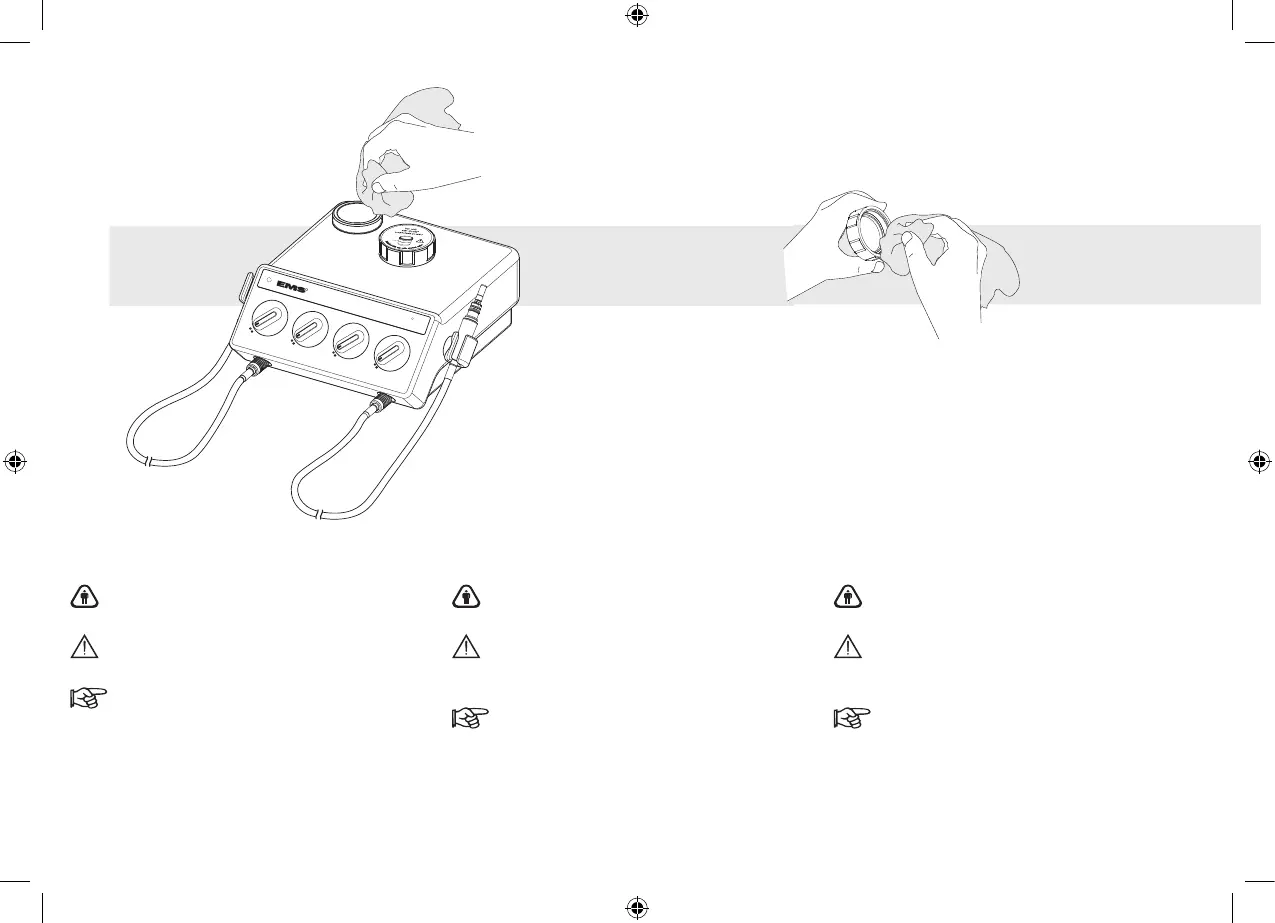

Clean the threads of the powder chamber before

screwing on the cap.

Ensure that the cap is not damaged. Re-

place faulty parts immediately.

Ensure that the powder chamber is closed

tight. Otherwise air and / or powder could leak.

Check the o-ring of the cap. Please refer to

the information provided in the chapter "Regular

Cleaning and Maintenance".

Loading...

Loading...