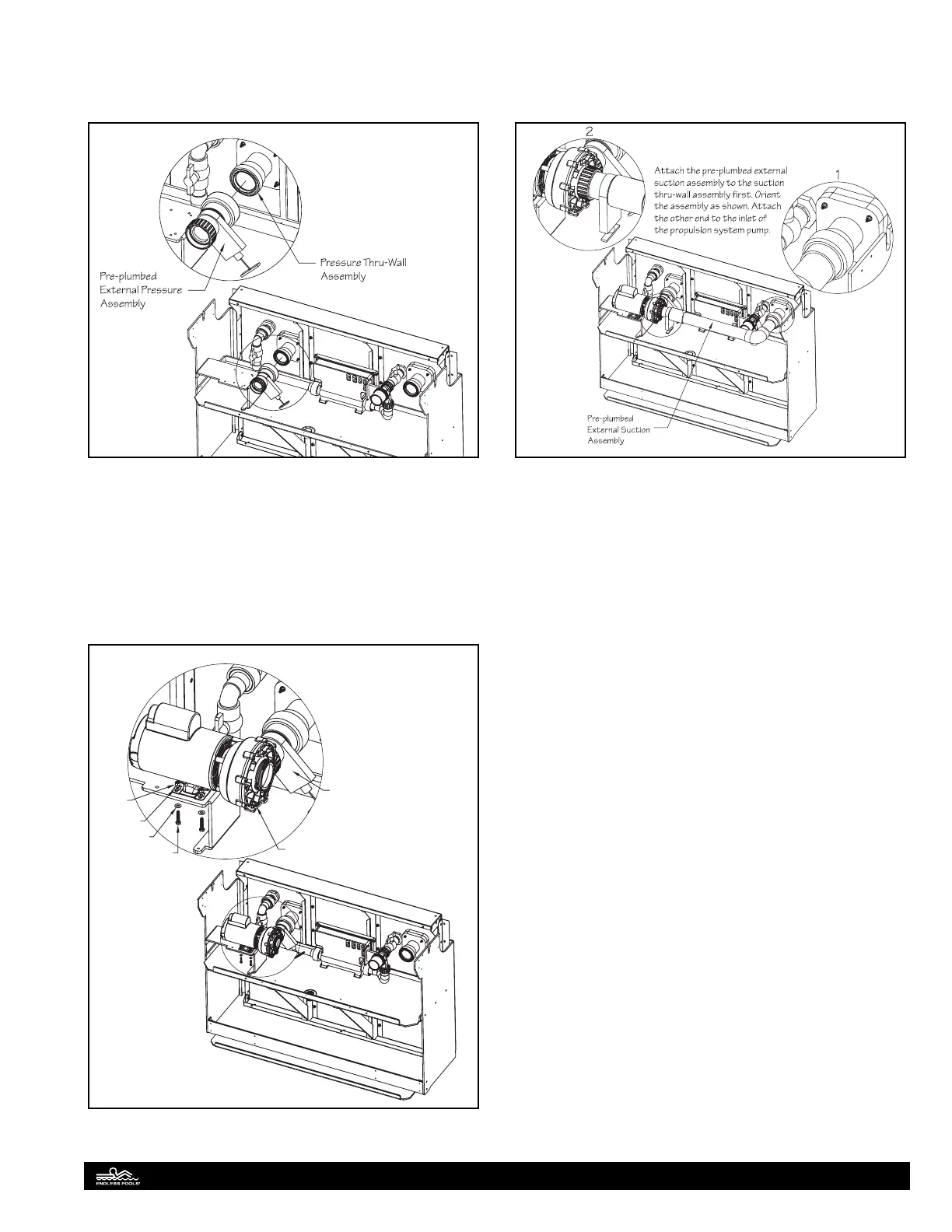

Propulsion System Plumbing

Attach the pre-plumbed external pressure assembly to the pres-

sure thru-wall assembly. Orient the assembly so the slide valve is

positioned as shown. Fig. 44

Fig. 44

Position the propulsion system pump on the pump support and

attach the pre-plumbed external pressure assembly to the outlet

of the pump. Fig. 45. Align the holes in the foot of the pump

with the holes in the pump support. Domestic (60Hz) pumps

will use the inside holes and Internatinal (50Hz) pumps will use

the outside holes. Secure the pump with the provided hex head

bolts, washers, and nuts located in the pump attachment hard-

ware bag.

Washer

Hex Head

Bolt

Propulsion System Pump

Pre-plumbed

External Pressure

Assembly

Washer

Nut

Fig. 45

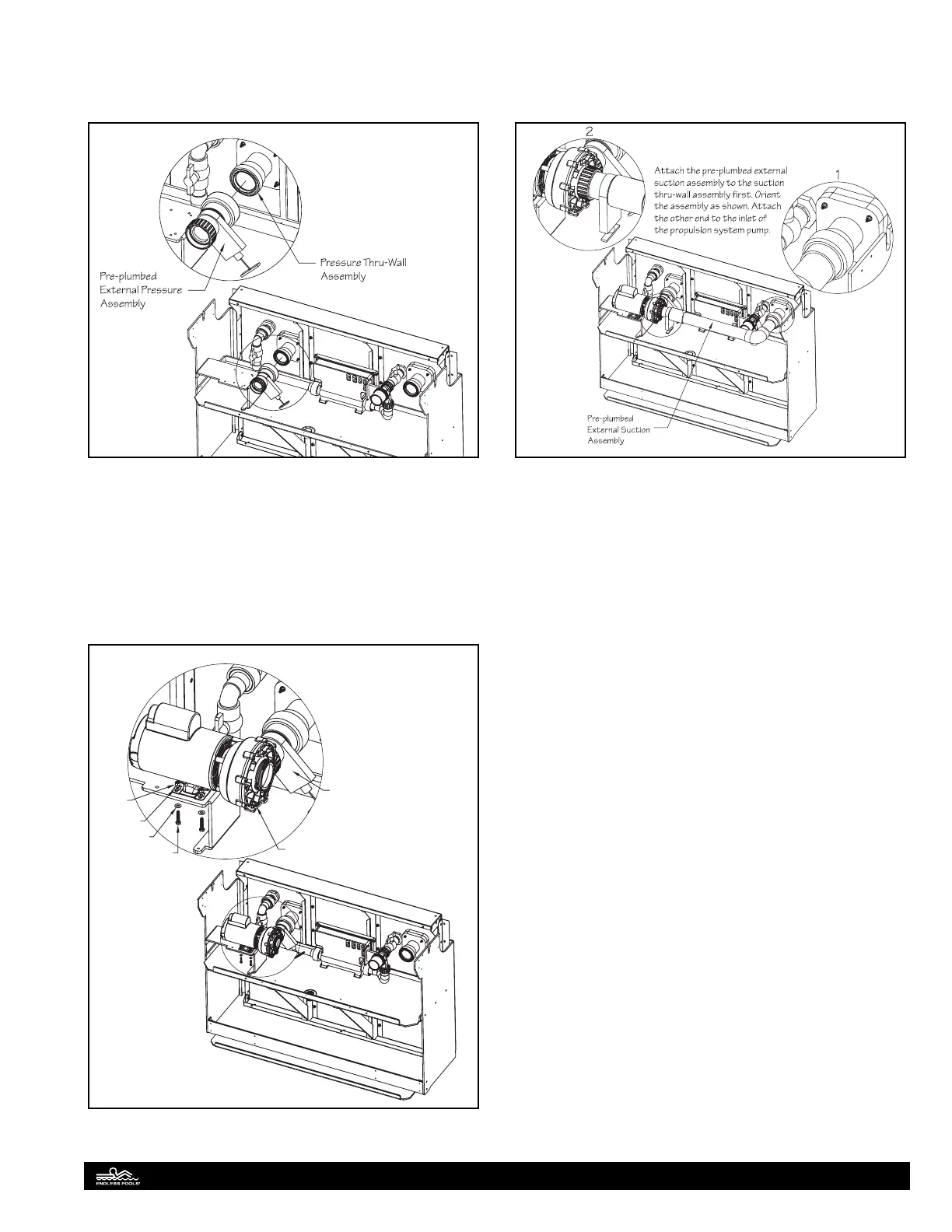

Attach the pre-plumbed external suction assembly to the suction

thru-wall assembly. Orient the assembly so that the slide valve is

facing down. Attach the other end of the assembly to the inlet of

the propulsion system pump. Fig. 46.

Fig. 46

Bonding

All of the electrical equipment supplied is UL or CSA approved

and must be installed in accordance with local electric codes by

a licensed electrician. Bonding and grounding is an important

part of the process. All electrical components have bonding lugs

and should be bonded together and to the steel pool enclosure.

A bonding conductor shall be solid copper not smaller than 8

AWG and may be insulated, covered, or bare. If new construction

is involved where reinforcing rods are installed in the concrete,

this should be included in the bonding circuit. Each piece of

equipment should be separately bonded.

A #8 AWG bare copper wire and bonding kit is provided to

bond each piece of equipment. Attach lengths of bonding wire

to the bonding lugs located on each pump (circulation pump and

propulsion system pump) and connect the bonding wires to the

bonding bar located at the base of the heater-controller. Included

in the bonding kit is a bonding lug, machine screw, nut, and drill

bit. Attach the bonding lug to one of Z braces (vertical braces of

the front panel) above the heater controller. Feed the bonding

wire through the bonding lug and then connect the wire to the

bonding bar on the heater-controller.

20

Loading...

Loading...