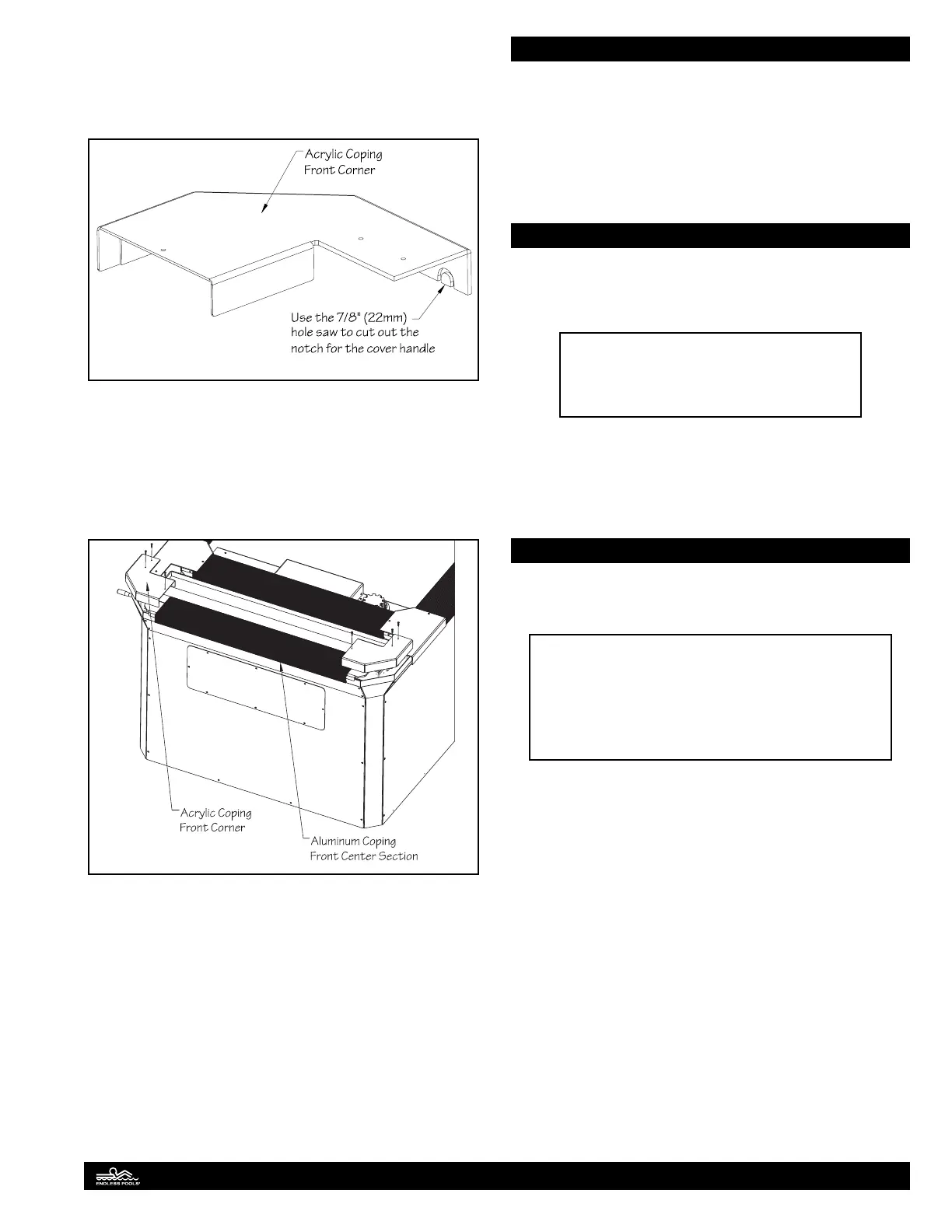

A notch will need to be cut in the acrylic coping front corner on

the side that the cover roller handle will be. ere is a “U” shaped

relief on the back of the front corner to use as a template. Use the

7/8" (22mm) hole saw to cut out the notch. Fig. 103.

Fig. 103

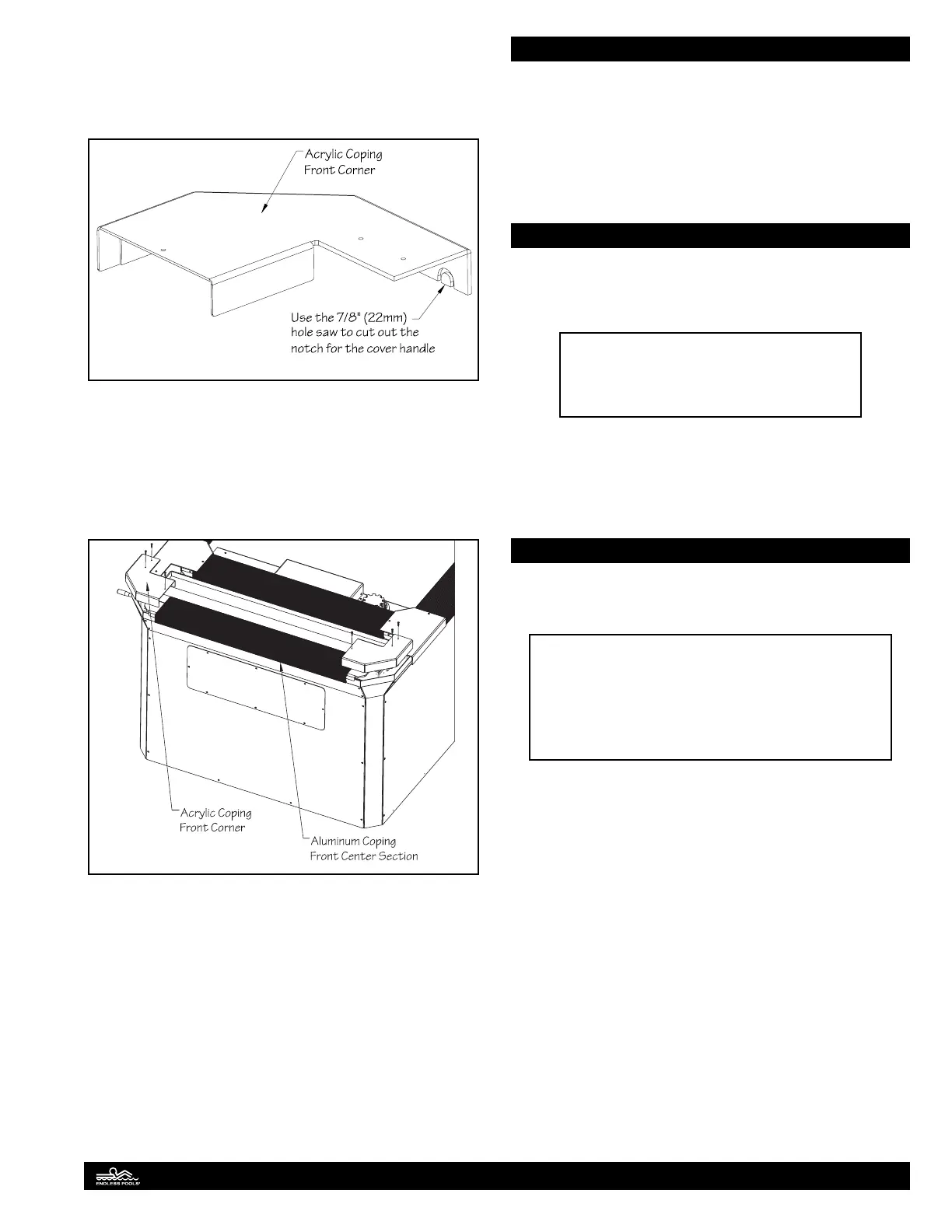

Position and center the nal aluminum coping center section

on the upper support beam. Position each acrylic coping front

corner. Use the 11/64" (4mm) drill bit to drill out the holes using

the pre-drilled holes in each acrylic front corner as a template.

Secure the front coping corners with the 3/4" (19mm) truss head

screws. Fig. 104.

Fig. 104

An additional Streamline Users Guide has been provided with

this pool. is guide provides a full overview on the pools func-

tions and maintenance. It is critical that these guides are refer-

enced on a regular basis.

Product Information Label

Included with the pool documentation is a product information

label (sticker) that MUST be lled out by the installer and ad-

hered to the product.

1. Fill out the Month/Year of Installation.

2. Adhere the label to the skirting access panel at the front of

the pool.

Product Installation Information

e product installation information MUST be completed by

the installer prior to using the product.

1. Fill out the installation information below

MONTH/YEAR INSTALLED_______

2. Hand the installation manual containing the above informa-

tion to the customer to be stored with other important pool

related documentation.

Suction Outlet Fitting Service Instructions

SUCTION OUTLET FITTING INFORMATION:

MODEL: STREAMLINE POOL

SUCTION OUTLET FITTING # 125020

SUCTION OUTLET FITTING FASTENER # 711330

Service Access. e use of adhesives or other attachment meth-

ods that prevent access to suction piping or suction outlet tting

components requiring periodic servicing is prohibited.

e suction outlet tting shall be replaced at or before the end

of the 25 year service life. e suction outlet tting and fasteners

securing the suction outlet tting should be inspected before each

use throughout its service life. e suction outlet tting MUST

be repaired or replaced if it’s missing, loose, dented, cracked, or

broken. e fasteners and corresponding receptacles MUST be

replaced or repaired if damaged.

When service is required to replace the suction outlet tting,

it shall be done so with replacement fasteners provided by the

manufacturer. e fasteners securing the suction outlet tting

are #10 x 3/4” (19mm) 316 Stainless Steel Phillips Truss Head

Screws. e fasteners MUST be installed using a #2 Phillips

head screwdriver. e recommended torque for the fasteners

is 25 inch-pounds. DO NOT USE POWER TOOLS TO

INSTALL FASTENERS. Start installation of the fastener

by hand to ensure proper thread engagement and to prevent

cross threading.

40

Loading...

Loading...