Prosonic S FDU90/91/91F/92/93/95/96

14 Endress + Hauser

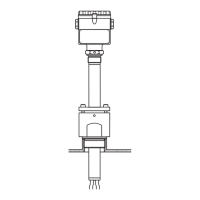

Nozzle installation Install the sensor at a height so that the blocking distance BD is not undershot, even at maximum fill level. Use

a pipe nozzle if you cannot maintain the blocking distance in any other way. The interior of the nozzle must

be smooth and may not contain any edges or welded joints. In particular, there should be no burr on the inside

of the tank side nozzle end. Note the specified limits for nozzle diameter and length. To minimise disturbing

factors, we recommend an angled socket edge (ideally 45°).

L00-FDU9xxxx-17-00-00-xx-006

Maximum nozzle length [mm]

Nozzle diameter FDU90

1)

1) mounted at the rear side thread

FDU90

2)

2) mounted at the front side thread (flush mounting)

FDU91 FDU91F FDU92 FDU93 FDU95 FDU96

DN50/2" 50

DN80/3" 340 250 340 250

3)

3) Valid for flush mounting; for mounting with G/NPT1" and DN100 or higher see FDU91F.

DN100/4" 390 300 390 300

3

DN150/6" 400 300 400 300

3

400

DN200/8" 400 300 400 300

3

400 520

DN250/10" 400 300 400 300

3

400 520 630

DN300/12" 400 300 400 300

3

400 520 630 800

Emission angle α 12° 12° 9° 12° 11° 4° 5° 6°

Blocking distance [m] 0.01 0.01 0,3 0,3 0,4 0,6 0,7 1,6

Max. measuring range

[m)

in liquids

3310102025

Max. measuring range

[m]

in solids

1.2 1.2 5 5 10 15 45 70

L

D

FDU9x

45°

L

D

FDU91F

45°

L

L

D

45°

L

45°

D

FDU90

FDU90

Loading...

Loading...