Turbimax CUS51D Operation

Endress+Hauser 35

Calibration of the sensor

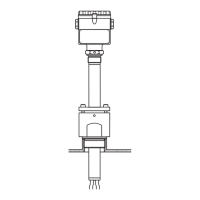

A0020487

33 Immersing the sensor

Preparing the sensor for calibration:

1. Clean the optical components (windows) of the sensor with water and a brush or

sponge.

2. Place the sensor into the calibration vessel.

3. The sensor must be placed in the sample at an angle, not vertically. → 33, 35

This prevents air bubbles from adhering to the windows.

Observe the following:

• Sensor LEDs are directed at the center of the calibration vessel.

• The minimum distance of the sensor to the vessel wall is 10 mm (0.4 in).

• The distance to the vessel floor is as large as possible. The sensor must be immersed in

at least 10 mm (0.4 in) of the medium, however.

‣

Secure the sensor in this position (ideally using a laboratory stand).

A0030900

34 Positioning the sensor. Dimensions: mm (in)

1 Beam direction of LEDs

2 LEDs

Note the following during calibration:

• The calibration points should cover the complete measuring range.

• During calibration, ensure that the medium is well homogenized (use a magnetic

stirrer).

• Determine the laboratory measured values with utmost care (the quality of the

laboratory measurement has a direct influence on the accuracy of the sensor).

• Apply maximum precision when dosing volumes for the sample and the dilution water

(use a graduated cylinder).

• Air bubbles on optical components significantly interfere with the calibration result. For

this reason, remove air bubbles before every calibration action.

Loading...

Loading...